Toyota Motor Manufacturing, Texas, Inc. (TMMTX)

Employment 27

Deep in the heart of our leading-edge San Antonio manufacturing facility, you'll find 2,600 Toyota team members proudly building some of the toughest trucks on the road: Our full-size Tundra and compact Tacoma Pickup. 5 The San Antonio plant is also our first plant to integrate production facilities for many of our suppliers on the same grounds, and some under the same roof. It's truly state-of-the-art. And the Lone Star State deserves nothing less.

1 Lone Star Pass San Antonio, TX 78264

https://www.tourtoyota.com/texas

Vehicles Produced 5

Sequoia Hybrid

Assembled Here 5

Cookie Consent

We use the following categories of cookies on our website:

Necessary and Performance Cookies

Necessary cookies are essential to provide you with the website’s core functionality. Performance cookies collect information about the performance of our website and how our website is used (e.g., basic site usage analytics, such as number of visits and time spent on the site).

Functional Cookies

Functional cookies enable us to provide enhanced website functionality, including Local Specials, Offers, Dealer Locator, etc. They also enable us to personalize the website with more relevant content related to your interests.

Targeting Cookies

Targeting cookies (also known as advertising cookies) collect information about your online activities for the purpose of delivering relevant advertisements across websites or online services.

- 0 . Includes all dealers and suppliers.

- 1 . Data as of 1/31/23.

- 2 . Represents "Outside-Company-Time" for CY 2020.

- 3 . All data as of December 2021, except where noted.

- 4 . Toyota vehicles and components assembled using U.S. and globally sourced parts (CYE2022).

- 5 . Parts, materials and components (CY2021). Goods and Services (CY2021).

- 6 . Represents direct dealer and Toyota-dedicated supplier employees (CYE2021).

- 7 . Includes U.S. (not HI) and Puerto Rico.

- 8 . As of CYE2023.

- 9 . Includes direct, dealer and supplier employees and jobs created through their spending.

- 10 . All data as of December 31, 2021, except where noted. All figures are rounded and reported as U.S. dollars, except where noted. State and location investment figures are based on different parameters; therefore, figures may vary.

- 11 . CY 2020.

- 12 . Cumulative to Date.

- 13 . As of December 31, 2020. May represent more than one location. Canada dealer totals include Lexus and Toyota dealers.

- 14 . Represents only a selection of parts purchased.

- 15 . As of August 2023.

- 16 . Figure is projected.

- 17 . As part of the brand transition beginning in August 2016, model year 2019 Scion vehicles will be rebadged as Toyotas.

- 18 . Based on Toyota data. Includes direct employees and dealer employees.

- 19 . Shown in U.S. dollars to reflect investment from US based operations of TEMA.

- 20 . As of CYE2021.

- 21 . Including our joint venture plant in Alabama.

- 22 . 2015 Center for Automotive Research Study. Includes direct, dealer and supplier employees, and jobs created through their spending.

- 23 . Employment and Investment are reflective of the combined TMMMO and TMMTN numbers.

- 24 . Data is CYTD as of 2/6/23.

- 25 . Data is CYTD as of 1/31/23.

- 26 . As of March 1, 2022. Includes on-site suppliers.

- 2012 Tundra Review

- 2011 Tundra Review

- 2010 Tundra Review

- 2009 Tundra Review

- 2008 Tundra Review

- 2007 Tundra Review

- New Tundra Buyer's Guide

- 10 Most Popular Accessories

- Cold Air Intakes

- Exhaust Systems

- Lift / Leveling Kits

- Tonneau Covers

- TRD Parts & Accessories

- Install Guides

- Exhaust Sound Clips

- Accessory Installs

- Diesel Tundra

- Hybrid Tundra

- 2014 Tundra News

- Tundra Links

- Tundra Events

THQ Tours Toyota Motor Manufacturing Texas Plant in San Antonio, Texas

Tim Esterdahl | Sep 20, 2016 | Comments 6

A common topic of discussion among Toyota Tundra and Tacoma fans is the Toyota Motor Manufacturing Texas (TMMTX) plant. Specifically fans want to know how the trucks get built, what the product mix is and how much capacity the plant truly has. Recently, Toyota flew me down to San Antonio, Texas to learn all of that and more.

A recent tour of the Toyota Motor Manufacturing Texas plant really showed how well the Tundra and Tacoma are built.

Now THIS is how you put wheels on!

Entering the TMMTX Plant

Passing through a security booth, the plant’s immense size is the first thing that grabs your attention. The second is more subjective for me. Let me explain. I visit plenty of manufacturing facilities and one of the things I’m always looking for is what vehicles the employees drive (I do the same thing at dealerships). My reasoning is simple: if the employees don’t believe in the product and personally own it, then why would consumers buy it? While this isn’t always the case since employees come and go and one can’t expect them to sell their old vehicle when starting at a new job, I do think it is still a good gauge of the product. Plus, the variety of vehicles can also speak to employee turnover. (note: photography is not available due to privacy concerns.)

After surveying the parking lot, I saw row after row filled with Toyota product and ALL the Tundra trucks featured the “Built in Texas, By Texans” sticker. Incidentally, I’ve been really surprised each time I’ve gone to Texas in the past year at seeing so many Tundra trucks on the road.

Watching robots work is pretty fascinating.

The Guided Tour

While I’m not often sure what I’m always staring at, I’m a manufacturing nerd really and love checking out how things are built especially trucks. I’ve toured Boeing, Nissan and many GM facilities. Many of these plants have things in common like moving assembly lines, safety lines to walk, workers trading off jobs and parts bin constantly refreshed. TMMTX is no different.

Throughout the tour, the assembly lines is in constant movement moving the vehicle to the worker rather than the worker walking to the truck. This allows them to complete their job before the truck moves to the next person. It is incredibly efficient and, as the story I was told by Boeing goes, Toyota was one of the pioneers of this system and shared its assembly line knowledge with Boeing. The aircraft builder uses the moving line as well with the massive planes moving really slowly throughout their plant. Toyota uses the same philosophy, as do other plants these days, and a new Tundra or Tacoma rolls out of the factory about every 26 hours.

All sorts of different cab configurations, trim levels and Tundra/Tacoma models pass down the line.

Quality checks this one are very common throughout the assembly process.

Lastly, the Kaizen philosophy is in full effect. Kaizen is Toyota’s core belief in continual improvement. This is evident along the line where there are different wires hanging overhead. At any point, an employee can pull the line to either indicate a problem, indicate a quality issue with the truck and/or pull the line to alert their supervisor of a way to improve the production assembly. At the end of the day, the supervisors get together to discuss each time someone pulled the line and discuss ways to improve the process with the employees feedback. Then, the next day, they implement changes. This dynamic improvement helps improve the entire process and creates happy employees who feel empowered by their work.

Flex Schedule and Staffing

One of the interesting parts of the TMMTX plant is the fact it sits in a non-industrial area. This is farm and ranch country. Hiring, training and developing assembly workers has been a constant challenge for TMMTX and it is also why it takes them time to ramp up to a third-shift. It simply takes time to find those employees. Also, keeping these employees is a big reason why the TMMTX plant found creative ways to keep the employees working during the downturn in 2009 when the plant basically shut down for several months. Employees did mock runs, maintenance and even community projects to keep a steady paycheck coming.

While I saw a lot of smiles on the tour, one does wonder how long morale will hold up with the schedule.

Finally, one item really caught my attention. There are several TV screens in the facility as well as other materials that talk about the automotive segment – recent sales, top stories, etc… It was interesting to me to see how much the employees are engaged with their industry and how they keep up on the latest news. In fact, I would wager many of them read this blog – so… good job ladies and gentleman! I was impressed.

One of these days, I hope to make a trip to the Indiana facility as well as other manufacturing plants. What do you think? Which assembly plant would you like to see?

The Million Mile Tundra got lots of attention from three waves of journalists.

Filed Under : Tundra News

Tags : toyota texas • toyota texas manufacturing plant • toyota texas plant tour

Comments (6)

Leave a Reply | Trackback URL

A tour of the plant is on my bucket list. Someday, plan to make the trip.

No question the assemble is first class. My Tundra has held up better than any truck I have owned before; in a class all by itself.

I’d be curious to see how the Tijuana plants compares to San Antonio.

That would be really interesting.

Thanks for building this beautiful car!

Greeting’s from Switzerland

I used to have a contract gig (IT, not mfg) at the Toyota Forklift plant in Columbus, Indiana. I imagine it is similar to what you saw. Clean, quality, etc. One thing I noticed was the nursery rhyme music constantly playing in the background. Was that going on at TMMTX? (BTW, they use a 4 or 5 letter acronym for all of their plants including industrial mfg). Also, as I understood it, every mfg facility ties into the same AS400 mainframe system globally and that system runs the mfg process. In Indiana they used a separate SAP instance (ERP software, does ordering, billing, etc.) but everyone interfaces into the AS400 system in Japan for mfg. That system drives the production you see on the floor. And only the Japanese are allowed to modify it. Others can extract data from it or interface from it, but only the Japanese in Japan can touch it – very tight control.

Anyway, some interesting nerdy IT stuff for those interested.

Yep, the nursery rhyme music is an audio code for supervisors to know the status of the line. When someone pulls the cord, the music changes and a supervisor is able to “hear” where the problem is.

- Most Popular

RSS Feed | Comments Feed

Get the latest updates via email.

Privacy guaranteed. We will not share your information.

This feature is not currently active.

Recent Tweets From TundraHQ

Most popular posts.

- Buying a Tundra

- Featured Vehicles

- Maintenance Tips

- Toyota Tundra Accessories

- Toyota Tundra Reviews and Comparisons

- Tundra Bed Liner

- Tundra Exhaust

- Tundra Hybrid

- Tundra Leveling Kit

- Tundra Lift Kits

- Tundra Lowering Kits

- Tundra News

- Tundra Recalls

- Tundra Supercharger

- Tundra Towing

- Tundra Videos

- Tundra Wheels and Tires

- TundraHeadquarters.com

"TOYOTA" and "TUNDRA" are registered trademarks of Toyota Motor Corporation . TUNDRA is used in the title of this website solely to identify the subject of interest to the website. Toyota Motor Corporation, Toyota Motor Sales, U.S.A., Inc. and their affiliated companies are not responsible in any way for the contents of the site, which are solely the responsibility of the publisher. The contents of the website do not reflect the policy or opinions of Toyota Motor Corporation, Toyota Motor Sales, U.S.A., Inc. or any of Toyota's affiliated companies. This website is not affiliated with, endorsed, sponsored, or supported by Toyota Motor Corporation, Toyota Motor Sales, U.S.A., Inc. or any of Toyota's affiliated companies .

Latest: Essential Truck Camper Glossary

Toyota Texas Truck Plant Factory Tour

Truck Camper Magazine tours the Toyota Motor Manufacturing Texas (TMMTX) plant in San Antonio, Texas. See truck bodies grabbed by Godzilla and Tacomas and Tundras made by man, machine, and a precision-guided fleet of roving robots.

In the spring of 2014, we contacted Toyota Motor North America to request a tour of the Toyota Motor Manufacturing Texas (TMMTX) plant in San Antonio, Texas. Specifically, we asked for an extended guided tour with unrestricted photography access for a feature story in Truck Camper Magazine.

Our original request was denied on several grounds. First, we hadn’t allowed for enough time for the required approval process. Toyota advised us to resubmit our request at least 90-days in advance the next time we would be in Texas.

Second, it was almost unheard of for outside media to be granted unrestricted photography access. We later learned that many major media outlets had been denied photography access and were provided Toyota approved photography for their visits.

Fast forward to the spring of 2017. We were scheduled to tour Capri Campers in Bluff Dale, Texas and attend the Texas Truck Camper Rally. Since we were already going to Texas, we once again engaged Toyota for a factory tour.

This time our request was granted, with two restrictions. I had to complete a Toyota security camera pass application right down to the camera model and serial number. The pass was only for my Nikon DSLR as no camera phones are allowed.

Additionally, there was a detailed safety dress code for the plant; no skirts, no shorts, no exposed midriffs, and no heels taller than one-inch. Well there goes the standard Truck Camper Magazine uniform!

1 Lone Star Pass

With the required forms submitted and the Stilettos safely back at the ranch, we arrived at 1 Lone Star Pass in San Antonio, Texas on April 3rd, 2017. After winding our way around the 2,000 acre Toyota Motor Manufacturing Texas (TMMTX) complex, we parked towards the back of the visitor’s center.

A few minutes later we were greeted by Melissa Sparks, External Media Affairs for Toyota Motor North America. Melissa handed me a laminated, signed, and date-restricted camera security pass with my full name and aforementioned camera serial number. Then she said, “If anyone asks you about your camera, show them this.” That’s right people. TCM got a unrestricted photo pass!

Melissa then had us board a 2017 Toyota Tundra, one of many Toyota trucks used around the TMMTX facility. She explained that these trucks were referred to as, “scrap” or text vehicles and had no VIN numbers.

Above: The TMMTX campus – photo provided by Toyota Motor North America

About thirty seconds later we were driving past the Toyota Family Heath Center, an on-site medical group practice for Toyota employees and their dependents including primary care, optical, dental, physical therapy, and a pharmacy.

The fact that Toyota made a medical facility part of their facility really impressed us. The $5 co-pay completely blew us away. If every major company took this forward-thinking approach to health care in the United States, we would have a much better health care situation today.

Two Story Truck Trains

The next stop on our tour was the shipping yard. Here the Toyota Tacomas and Tundras are loaded onto two-story rail cars and trucks for distribution throughout the United States and Canada. About 90-percent are shipped by rail.

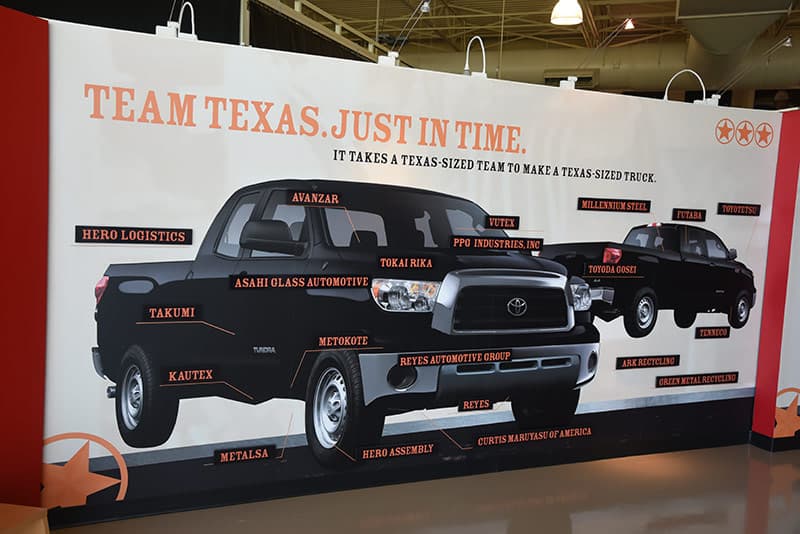

As we drove towards the main assembly building, we passed dozens of on-site suppliers. The Toyota Texas Truck Plant was the first automotive facility to position suppliers on the same grounds as the main assembly plant.

These automotive suppliers manufacture door glass, seats, headliners, door panels, steering wheels, switches, carpet, windshields, fuel tanks, exhaust systems, stamped parts, tire and wheel assemblies, and more. This on-site supplier integration saves time and shipping costs, improves overall manufacturing efficiency, and allows for a better partnership between the suppliers and Toyota.

Another thing we noticed on the Toyota campus was a lot of large empty lots surrounding the various buildings. Melissa explained that Toyota purposefully left these empty lots for future expansion. Japanese companies are well known for their long term planning sometimes stretching decades into the future.

Stop That Guy With The Camera!

The main entrance to the main assembly building looks more like a large hotel lobby entrance than your typical automotive factory. Having been to a few other major automotive factories, they don’t normally look like this.

Once in the door, the security guys immediately noticed my Nikon. Thankfully, Melissa quickly explained that I had a one-day camera pass. No need to tackle the magazine publisher. He’s legit!

Melissa then introduced us to Mario Lozoya, Director of Government Relations and External Affairs for Toyota North America. Mario and Melissa then led us to a room off the main entrance to be fitted with steel tipped shoes, hard hats, safety glasses, and belt-buckle covers. This last item was not my favorite fashion accessory of the day.

The Blue Double-Doors

From there we walked past the 1-millionth Toyota Tundra produced at TMMTX, through blue double-doors, and into the truck plant. We were finally in the building.

The first thing we saw were a series of large monitors displaying production data for the plant. We were asked not to show this information, but essentially these screens detailed where the plant was in efficiency and other critical metrics, over time.

The fact that Toyota puts this information upfront for all employees to see and study is an important part of the Toyota culture. They strongly believe in measuring every facet of efficiency, and then empowering the entire workforce with this information.

Stop, Look, and Point

Walking paths are clearly defined throughout the plant. When you’re about to cross an area used by delivery vehicles, forklifts, and automated robotics, you find a white circle like the one pictured above.

At these white circles, Toyota team members stop and physically point and look towards the left, right, and straight ahead before proceeding. At first it seems really weird to have grown adults stopping, pointing, and looking before walking across a pathway. Everyone in the plant follows this safety protocol no matter their rank. It’s the law at Toyota.

“It does seem funny at first,” explained Melissa. “But it’s how we prevent our team members from stepping out in front of a robot or vehicle.” She went on to reveal that she’s caught herself pointing and looking at the end of grocery store aisles and parking lot crossways.

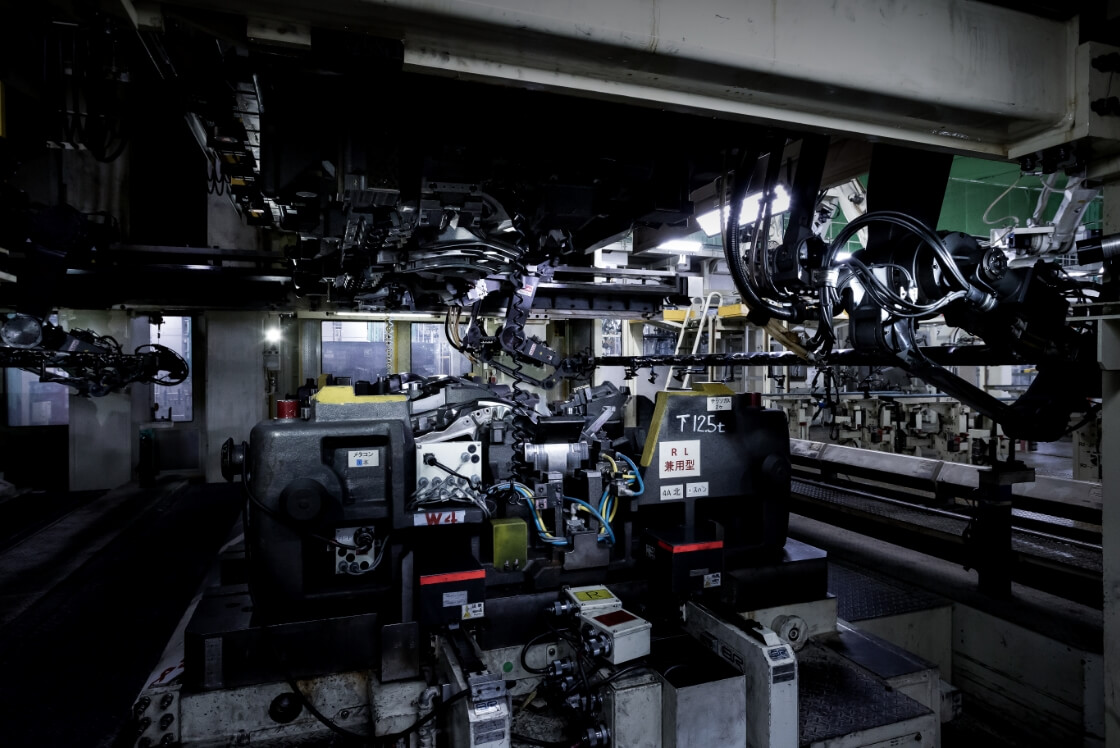

Robots Running

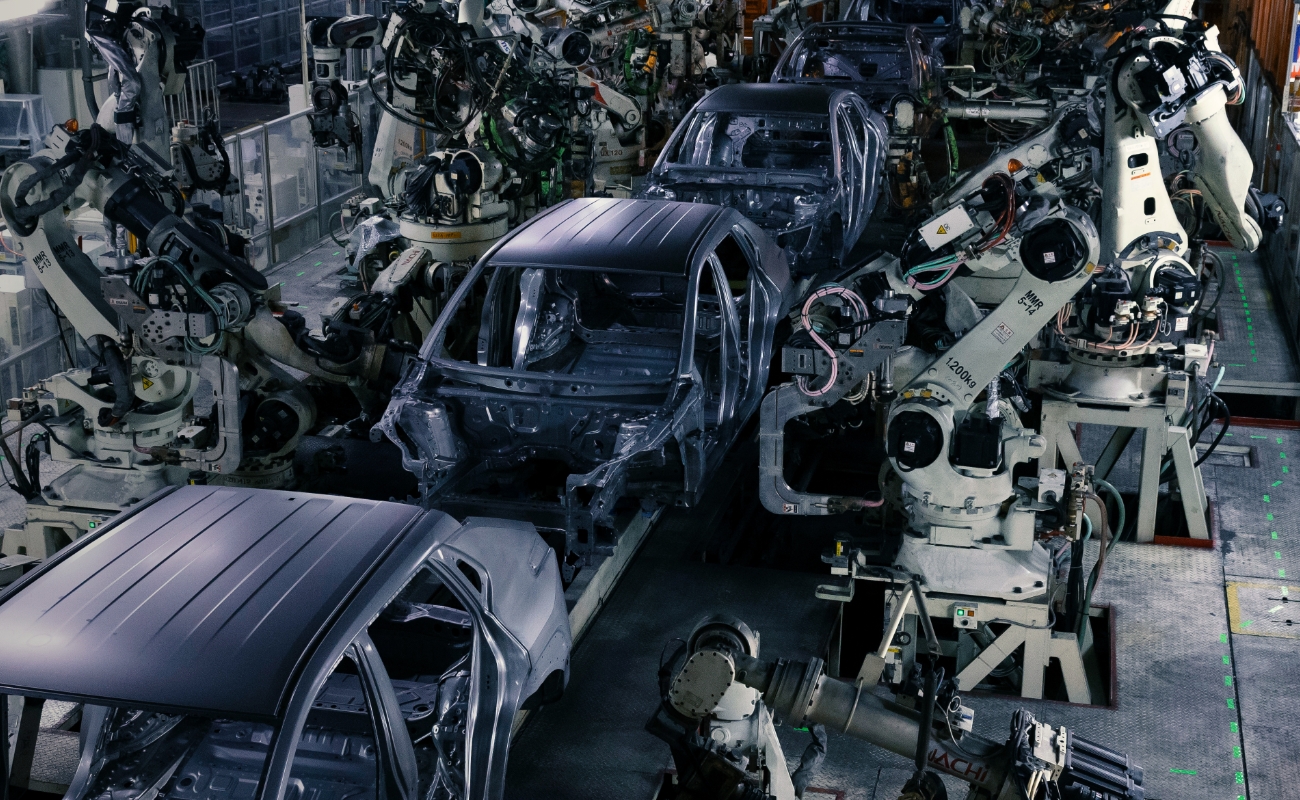

Speaking of robots, they were everywhere at Toyota.

The first robots we saw looked like long industrial skateboards emblazoned with the Toyota logo and blinking away with red and green lights.

These skateboard robots were ferrying around stamped Tacoma body panels.

As a life-long fan of science fiction, it was surreal to see these seemingly autonomous robots go about their business.

Melissa stated that the robots were following tracks laid into the floor and delivering parts to the production line just-in-time. This automated and reliable just-in-time delivery eliminates the need for storing inventory inside the plant.

Progressing deeper into the plant, we asked about where we might see metal stamping and welding. Mario answered that those processes were 100-percent robotically controlled and inaccessible for photography. This was disappointing, but it’s Toyota’s plant, and rules.

Dashboards In a Dash

Mario then proceeded to where the dashboards are installed.

Along side the production line, more skateboard-like robots delivered the exact right dashboard, to the exact right place, at the exact right time.

The entire factory runs like a Swiss watch; robotic and human gears intermeshing in perfect rhythm. It works so well that you almost don’t appreciate it.

As we observed, human Toyota team members used robotic arms to lift the dashboards off their robot cradles and smoothly guide the dashboards to a truck on the production line for installation.

When a dashboard was removed from a cradle, that robot sped away and another robot pulled up with the next dashboard. Tic-Toc, Tic-Toc.

Godzilla – King of the Monsters!

Centrally located in the Toyota factory is the largest robot in the plant; a giant robotic arm that picks up freshly welded truck cabs from the second story and gently lowers them onto the first floor production line.

Watching Godzilla go about its routine is beautiful and a bit terrifying. The robot’s motion is as fluid and graceful as it is direct.

As you watch Godzilla effortlessly pick up truck cabs that weigh north of 1,000 pounds, you wonder what all that power could do unleashed on the streets of San Antonio.

Look out Texas! Run for your lives!

Immediately following Godzilla, the unpainted truck cabs enter a shine bay and are thoroughly inspected prior to paint. This continues the pattern of man and machine working side-by-side to serve the ultimate goals of quality and efficiency.

Brass Knuckle Vending Machine

As we were walking through the plant, an odd vending machine caught our attention. Usually when you see a vending machine in a factory it’s dispensing candy and soda pop. Well, we found this vending machine in the Toyota plant offering brass knuckle safety gloves.

At first blush, brass knuckle gloves sound more like something Johnny Bananas and Frankie Fingers would wear to a mob hit than anything they might need at Toyota.

As turns out brass knuckle gloves are light weight, highly flexible, and cut-resistant safety gloves. From our own observation, the majority of production line team members wear these special gloves.

Engine and Transmission

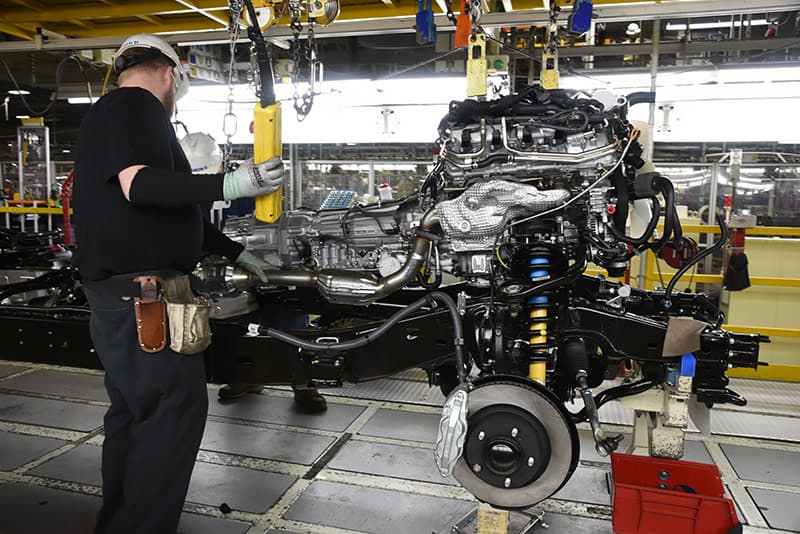

Heads up! Big heavy things regularly appear and drop out the ceiling at Toyota. One of the more impressive examples are the truck engine and transmission assemblies.

About ten feet above the production line, yellow gate doors open allowing a truck engine and transmission assembly to descend directly over a corresponding truck chassis.

Once hovering above the chassis, a two man team guides the engine and transmission into the truck chassis. The next station inspects the installation and secures the engine and transmission into place.

Marriage Ceremony

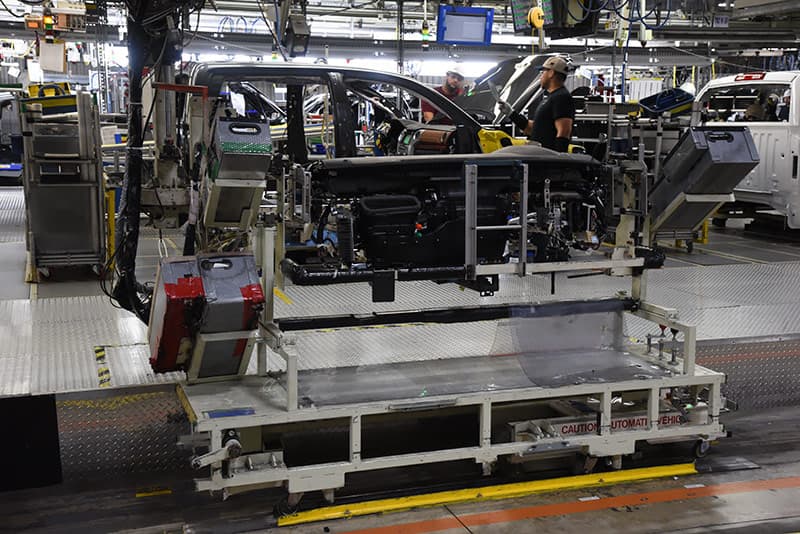

Trucks are assembled in two large sections; an upper section (truck cab and bed), and a lower section (chassis, transmission, and engine).

These two sections run on separate production lines and then are married together by an enormous two-story robot. All of this precision flying is done as the truck moves down the production line.

“Do you 2017 Barcelona Red Metallic Tacoma and bed take this truck chassis, transmission, and engine to be your lawfully wedded underbody?”

I took about 35 photos of the marriage ceremony and assembled them into the animated GIF/video above. Note how the upper section is brought down from the second floor to meet the lower section in a series of smooth motions.

It’s amazing that the right cab and bed always marry the right chassis, transmission, and engine. No prenup necessary.

Wheels and Tires On

Another area where man and robot work hand-in-machine together is the wheel and tire installation. The first amazing fact is how the right wheel and tire are delivered down a tire elevator as the truck arrives on the production line.

The wheel and tire are then picked up by a human Toyota team member using a robotic arm and guided towards the next truck as it moves down the line. Notice the truck is elevated for efficiency and ergonomic comfort for the human workers.

Once the wheel and tire is properly placed, the same Toyota team member guides a specialized robot that precisely tightens the wheel bolts.

This wheel tightening robot moves with the truck down the production line tightening the bolts, and then back into position for the next truck. The whole process is beautifully orchestrated, like a dance between man and machine.

The complexity of the landscape within the plant is often mesmerizing. Just as you’re getting accustomed to robots and humans working hand-in-machine, you notice the myriad of truck bodies, seats, doors, and other truck elements moving along the ceiling, raised cat walks, and between the production lines on computer controlled conveyor systems.

Final Inspection and Truck Whacking

As the Tundras and Tacomas roll toward the end of the production line, they are meticulously inspected from hood to tailgate.

To check various exterior tolerances, the team uses calibrated foam wands that reveal any sheet metal or body fitting that is out of specification.

The team also uses their sense of touch and hearing opening and closing the hood, cab doors, and tailgate feeling and listening for an incorrect fit. If you open and close a Tundra hood a few thousand times, you know exactly what that’s supposed to feel and sound like.

To make minor adjustments to a hood or door installation, the team uses soft rubber mallets to give exactly the right tap at the exactly the right place to put a truck into perfect alignment. If these guys ever get tired of trucks, they’d make great chiropractors.

Truck Hospital

At the very end of the production line is an area Melissa described as the Truck Hospital. Here trucks that did not pass final inspection are held, have their issues addressed, and are then re-inspected.

Speaking of inspection, we saw an amazing number of shine bays at Toyota. Some, like the shine bay shown above, are off the production line and designed for a whole truck inspection.

Others exist on the production line and focus on various aspects of the truck; underbody, sheet metal, etc.

Music On the Line

A few times during our tour we heard music playing in the factory. This wasn’t exactly Beethoven, but rather melodic computer tones. Melissa said this music only plays when the production line has been halted somewhere in the plant. This happens when a team member recognizes an issue on the production line.

The employees are encouraged to stop the line anytime they see a quality control issue. These incidents are part of Toyota’s renown quality-control practices and are later studied for opportunities to improve.

Before we left the production line, Melissa took us into a room just off the factory floor with hundreds of charts and graphs tracking these and other factory efficiency information sources. Every slice of data in that room was displayed visually for quick analysis. Team leaders gather around these charts and graphs daily to discuss ways to improve.

As a side note, we didn’t hear any other music playing on the production line. In most RV factories, the team is permitted to play classic rock or whatever gets them through the day. Not at Toyota.

The Kaizen Lab

Towards the back of the plant Melissa showed us an area devoted to Kaizen – the Japanese word meaning “constant improvement”.

This research and development laboratory studies the efficiency data, quality control reports, work station ergonomics, and team feedback and finds ways to constantly improve quality, efficiency, safety, and worker comfort. Kaizen is literally applied to all functions of management and production at Toyota.

Much of what you find at Toyota is the direct result of their dedication to Kaizen – from the robots moving materials throughout the plant to cradles and conveyor systems that bring a work process to exactly the right height for a team member. Melissa explained that Toyota employees are encouraged to find Kaizen approaches to everything they do, even the arrangement of their desks.

The totality of Kaizen really comes into focus when you realize that every Toyota factory has a Kaizen laboratory and has been working on continuous improvement – and sharing their Kaizen research with other Toyota factories – for decades.

Imagine if the RV industry adopted Kaizen as deeply as Toyota. How much better would the quality, efficiency, and profitability of the RV industry be today?

To be fair, some RV manufacturers have embraced elements of what is commonly referred to as the Toyota Method or Toyota Production System (TPS). The most popular TPS concepts within the RV space are just in time production and lean manufacturing.

The difference between what some RV manufacturers practice and what Toyota practices is in the depth, breadth, and culture. Where the RV industry might apply a few elements of TPS when it’s practical to do so, Toyota applies it to every facet of management and production every day.

Thank You, Toyota!

Above: Melissa Sparks of Toyota Motor North America and Angela White of TCM

We want to thank Mario Lozoya and Melissa Sparks of Toyota Motor North America for their time and effort. They went out of their way to give us an extended private tour of the TMMTX facility and were a fountain of helpful information before, during, and after our visit. Thank you!

Recommended for you

Home » Factory Tours » Toyota Texas Truck Plant Factory Tour

Campers for Sale

- Request Information

- Subscribe Free

- RV Shows & Rallies

- 31.2k Followers

- 45.8k Followers

- 6.1k Followers

- 22.5k Followers

Latest Content

The essential truck camper glossary.

TCM presents 35 critical terms and expressions for every truck camper owner. This is...

Safer Stairway to Heaven

Chuck Ramsey installed Torklift Stow N’ Go scissor steps on the Fox Landing platform...

PowerMod Contest Winner: March 2024

Mark Joslin has won the third PowerMod contest of 2024 with his Compact and...

6 Easy Ways To Load Your Truck Camper

Looking for a faster, easier, and more reliable way to load your truck camper? ...

TCM EXCLUSIVE: 2024 Grumpy Bear Arctos Sport

Grumpy Bear reinvents their fiberglass truck camper process and debuts an all-new hard side...

More Latest Content

- New Camper Arrivals

- Used Truck Campers

- Closeout Campers

Manufacturers

- Lance Camper

- Northern Lite

- Hallmark RV

- Alaskan Campers

- Palomino RV

- Soaring Eagle

- Cube Series

- Supertramp Campers

- Northstar Campers

- Four Wheel Campers

- Phoenix Campers

- Capri Campers

- Overland Explorer

- Rugged Mountain

- Grumpy Bear

- Total Composites

- Hotomobil US

Gear Companies

- Torklift Intl.

- Rieco-Titan

- Hellwig Products

Toyota Motor Manufacturing Visitor Center

Location & Hours

Suggest an edit

1 Lone Star Pass

San Antonio, TX 78264

You Might Also Consider

Set Sail Travel Agency

Set Sail Travel Agency has certified cruise specialists ready to help you plan your next perfect vacation! What bucket list trips can we make come true for you? read more

in Travel Agents

Bucket List Travel Solution

Bucket List Travel Solution combines curated experiences, cultural immersion, and positive impact, making it a standout choice for travelers seeking extraordinary adventures. read more

Ranger Creek Brewing & Distilling

Stephen M. said "Amazing whiskeys, bourbons and beers. The tap room is smaller and a great spot for conversation and beverages. The bourbon barrel wee heavy is one of my favorites." read more

in Breweries, Tours

Recommended Reviews

- 1 star rating Not good

- 2 star rating Could’ve been better

- 3 star rating OK

- 4 star rating Good

- 5 star rating Great

Select your rating

Overall rating

Really cool your! Great for kids, teens, adults and old people. Toyota really goes above and beyond. They have a gym at the plant where you can consult for free with PhD kinesiologists, legit dietitians, as well as doctors and nurses on staff the support their employees. They are big on ergonomics and making the job absolutely comfortable for the people working these manufacturing jobs. 22 hours to bulls Toyota Tundra from start to finish. The automation here is truly amazing! I am excited to see what is going to be in place in the next ten years. This Plant employs 7000 people in the San Antonio area. 3500 are Toyota employees and the rest are employed by companies that are part of the just in Time manufacturing. They truly have their process streamlined. This is why I will always drive Lexus. Their quality is top notch!

Worth it! My expectations of car factory were pretty low. What can they show us we don't already know, 4 wheels, engine and a frame. Done. So much more! This place is fantastic you see it all within safety reasons of course. It's a Tram ride with the tour guide. You first see a short history video then it's off to the factory part. No cell phones or camera inside factory, only in lobby area. They give you earphones so you can hear the tour guide explain every stop. You do have to set reservations. I did mine 2 weeks in advance. I had the 9am spot and we were full.

Going to start off by saying, I may be a little bias. I'm a huge Toyota fan, we've been a Toyota family, and yes, I'm one of "those guys" that has a name for my Tundra . Been wanting to come check out "the Mecca" for a while now, to see how these amazing vehicles are made, and boy, did this place not disappoint. First off, it's free, so can't beat that, and once you see the work and methods put into this place, you won't look at your beloved truck the same ever again. This place is pretty much like Fort Knox, once you exit the visitor center. No phones, no cameras, nothing. When you pull into the main entrance, keep in mind to keep to the right to go to the Visitors center first, and you'll have to book a tour in advance online before coming, even on a Wednesday at 1:30p, our tour was completely packed. I would have hoped for a little more from the Visitor's center, but it was cool, had some neat little history and displays on the process they use to build, few interactive things you're kids would enjoy. After everyone goes through a little "intro video" you then drive your own vehicle if you came in one and not a shuttle, over to the main plant. This is where you'll leave your cameras / phones in your car and then follow the tour guide. Once you go in, I swear it feels like some futuristic movie or on the set of Wall-E in real life. You got automated robots running around with truck beds, huge giant robotic arms doing things with impossible precision, and so many workers in fork-lifts and walking around, punching buttons, drilling things, operating machines, in little pow-wow meetings looking over graphs, it's all pretty amazing. I won't go in detail of the actual tour, you just gotta come check it out for yourself. But I will say this, I would have still probably gone here even if the tour cost something, but it's free! Which is even better. So even if your a Yota fan, this is well worth the visit to see how amazing the whole entire process is to build these vehicles, how very earth-friendly minded they are and just an overall cool experience.

We recently toured the Toyota plant. Though thoroughly in love with Toyota, the tour was a bit dry in terms of the delivery of the information. As a whole, witnessing the machines, people, robots and conveyor-belt-antics was an overwhelming experience. To see the dance, hard work and ingenuity that it takes to produce an entire Tacoma or Tundra is a thing to behold. However, the delivery of the information was done in the style of ... meh... i dunno. It was this rehearsed, heartless spiel. Scripted and informative, I didn't sense any connection from the tour guides about how much they LOVE the company, the product, the work or the belief system. It's hard to put words down to match up with what was wrong with this tour, but it was about an impersonal as listening to a flight attendant tell you about the floatation devices. I had REALLY high hopes for the tour, and it didn't meet my expectations. Alas, the tour IS free so I do recommend going on it.

This is my second time coming on this tour and you learn so many things! The girl who showed us around knew all the facts and was helpful. I saw a lot of interesting things but sadly I couldn't take pictures since they don't allow phones on the tour, but I did have fun.

2 other reviews that are not currently recommended

AplusRTravels & Adventures

"Discover unparalleled travel experiences with our agency! We craft personalized journeys, blending expertise with passion. From hidden gems to iconic destinations, our attention to detail ensures your adventure is one-of-a-kind.… read more

Moab Luxury Tours

We offer guided tours of Moab area National Parks from the comfort of an SUV limo, all while enjoying the cool, refreshing tastes of local beers and wines. Great views, great friends, life is good! read more

People Also Viewed

San Antonio Detours

San Antonio Museum of Art

SA Food Tours

Gray Line Tours - San Antonio

Sisters Grimm Ghost Tours

CycloFiesta

Bad Wolf Ghost Tours

Alamo Helicopter Tours

GO RIO San Antonio River Cruises

Fork in the River

Best of San Antonio

Things to do in San Antonio

Other Visitor Centers Nearby

Find more Visitor Centers near Toyota Motor Manufacturing Visitor Center

People found Toyota Motor Manufacturing Visitor Center by searching for…

Factory Tours San Antonio

What To Do Around San Antonio San Antonio

Browse Nearby

Restaurants

Places to Go Near Me

Visitor Centers Near Me

Related Cost Guides

Town Car Service

This Toyota-focused site copyright © 2000-2023 Zatz LLC.

- San Antonio

- Things to Do

- Restaurants

- Vacation Rentals

- Travel Stories

- Rental Cars

- Add a Place

- Travel Forum

- Travelers' Choice

- Help Center

Great Tour - Toyota Motor Manufacturing - TMMTX Experience

- United States

- Texas (TX)

- San Antonio

- San Antonio - Things to Do

- Toyota Motor Manufacturing - TMMTX Experience

We recently went to Toyota to do this tour. First, we found out you need to reserve a spot either... read more

Good free event for families with men and teen boys, but interesting even for girls. This is an... read more

We have visited San Antonio many times and I was searching Trip Advisor looking for something new to do. I found this tour decided to try it so I booked it. We were in town for my husband's birthday and he is a big Toyota fan so I thought he might like it. You go to a visitor's center first and can take pictures there if you like. It was very interesting, kind of like a Toyota museum. I wish we had gotten there earlier, we didn't see it all in 40 minutes. Then you drive over to the factory and ride a tram through it on a guided tour. They take you everywhere but the metal fabrication and paint areas. It was about an hour long and very interesting to see. There were people of all ages on the tour, even some children and everyone seemed to enjoy it. My husband liked it so it was a success for us. I'd say it's a must see. There is no charge for the tour. I would get there at least an hour before the tour starts to see the visitor's center.

You should visit if you want to see the inner workings of a modern automotive factory. It is very interesting.

This tour requires an advance reservation, so plan ahead. Allow 30 minutes prior to the tour to view the exhibits in the visitors center. I recommend viewing the many auto manufacturing videos on YouTube prior to your visit to better understand what you're seeing in the Toyota plant. Our guide was good but had a pronounced accent. This, with the noise of the factory, made it hard to hear his narration. I highly recommend the tour; it is amazing to see the coordinated effort required to manufacture a truck

This factory tour is awesome!!! You will need to make reservations online prior to going. Once there, you will visit a museum area and then take a tram-guided tour. The tour is fascinating and takes you through the production line from beginning to end. One of the most enjoyable factory tours I have taken and especially enlightening for older children and teens.

This plant tour is free but don't bring bags or cameras, they can't go on tour. This plant only makes the trucks but still pretty interesting. You go in the entrance and then drive your own car to a parking lot where you ride in a tram during the actual tours. You wear a headset and listen to the guide. You get to see quite a bit but you do not get off tram.

My 13 year old son has expressed an interest in becoming an auto designer/engineer as a possible vocation when he gets older. I thought this would be a great place to visit during our Spring Break trip to San Antonio. We were not disappointed! We were gathered and giving a quick pre-tour review and then shuttled over to the factory. We were given ear pieces to listen to the tour while our tour group was driven around the factory in a large golf cart type vehicle. We were able to see the trucks being manufactured at various points of the manufacturing process. My 84 year old father and 10 year old daughter also enjoyed the tour. I would suggest arriving about 30 minutes before your scheduled tour time to look around their visitor center for a Toyota history lesson as well as an opportunity to look at several trucks.. Very interesting!

Search this Site:

Texas factory tours | see it made in the usa.

Some of the links on this page may be affiliate links. As an Amazon associate, I earn from qualifying purchases. There is no additional cost to you when you make a qualifying purchase via an affiliate link. Click here for the full affiliate disclosure.

Take a Made in America Texas Factory Tour

The Lone Star State has quite a few interesting Texas factory tours to choose from. You can see everything from the American dollar being printed, to the production of baseball gloves, shoes , boots , cars, and more. Texas also has a handful of dairy farms you can visit , chocolate factories , and distillery tours .

Texas Factories That Offer Tours

Bureau of Engraving & Printing | Fort Worth, TX

The Fort Worth, Texas Western Currency Facility produces more than half of United States currency. See where billions of dollars are printed from an enclosed walkway suspended above the production floor.

#Bureau of Engraving & Printing

Dr. Pepper Museum | Waco, TX

Scheduled group tours and field trips to the home of the original Dr. Pepper take visitors to both historical buildings. Children on field trips get to make their own soda.

Visit the Official Dr. Pepper Amazon Store

#Dr. Pepper

James Leddy Boots | Abilene, TX

The Dos Santos family is happy to provide you with a tour that shares some of the heritage of James Leddy Boots including purchase receipts that date back to the 1930s and even contains celebrity names that bought custom styles.

#James Leddy Boots

Nokona | Nokona, TX

Nokona has been making made in the USA baseball gloves in Nokona, Texas since 1934. See every part of the baseball glove making process from leather selection to cutting, stamping, embroidery, forming, stitching, and lacing on this Texas factory tour.

I’d rather take a bucket of worms and go fishing than import Nokona gloves. R.E. “Big Bob” Storey, President, Nokona Ballgloves, 1965

Visit the Official Nokona Amazon Store

SAS | San Antonio, TX

Head over to San Antonio Shoes to see how SAS creates some of the world’s most comfortable shoes. See first-hand how each pair of shoes goes through up to 100 different steps and is performed by approximately 80 different SAS employees.

Shop SAS Shoes on Amazon

Toyota Texas Experience Center | San Antonio, TX

Free, tram-driven tour through the birthplace of the Toyota Tundra and Sequoia. Experience how people and machines work together to build vehicles.

Wimberly Glassworks

Wimberly Glassworks invites you to come out to the gallery for live glassblowing demonstrations. Private group demonstration are also available by scheduling at least a week in advance.

#Wimberly Glassworks

More Tours in Texas

Texas Chocolate & Candy Factory Tours

Made in the USA Matters has a complete directory of United States chocolate and candy factories that offer tours . Check out the chocolate and candy factory tours in Texas .

Texas Dairy Farm Tours

Made in the USA Matters has a complete directory of United States dairy farm tours . Check out the dairy farm tours in Texas .

Texas Distillery and Brewery Tours

Made in the USA Matters has a complete directory of United States distilleries and breweries that offer tours . Check out the distillery and brewery tours in Texas .

USA Factory Tours

Did we miss a Texas factory tour? Please share it with our community in the comments below.

American Dairy Farm Tours | See Dairy Products Made in the USA

American Cheese Factory Tours | See Cheese Made in the USA

American Chocolate & Candy Factory Tours | See Chocolate & Candy Made in the USA

American Potato Chip Factory Tours | See Snack Foods Made in the USA

American Distillery & Brewery Tours | See Spirits Made in the USA

Pin it texas factory tours.

Your saves and shares help other Americans find products that are Made in the USA. Thank you!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Made in the USA Product Categories

Baby & Toddler

Clothing & Shoes

Electronics & Accessories

Farm & Ranch Equipment

Food & Drinks

Hobbies & Leisure

Home Furnishings

Household Essentials

Patio & Garden

Personal Care

School & Office

Sporting Goods & Recreation

Tools & Home Improvement

© 2024 madeintheusamatters.com

- Share on Facebook

New! Made in the USA Matters Facebook Group

Join the Made in the USA Matters Facebook Group where you can ask for USA-made product recommendations, request we find an American-made product you're looking for, and help others find Made in the USA products they need.

We welcome Made in the USA consumers and manufacturers!

Car Production Process

- Power Unit Craftsmanship

- Toyota Production System

Return to the Toyota Motor Corporation website

- 01 STAMPING --> STAMPING

- 02 WELDING --> WELDING

- 03 PAINTING --> PAINTING

- 04 ASSEMBLY --> ASSEMBLY

- 05 INSPECTION SHIPPING --> INSPECTION SHIPPING

--> Manufacturing Process Overview Video

A browser that supports the video tag is required to play the video.

E x p e r i e n c e t h e W o n d e r a n d C r a f t s m a n s h i p o f T o y o t a ' s M a n u f a c t u r i n g P l a n t s

Cars are made up of some 30,000 parts - all filled with care and craftsmanship in every step of production. People are the heart of Toyota's manufacturing.

Cars are made up of some 30,000 parts - all filled with care and craftsmanship in every step of production People are the heart of Toyota's manufacturing.

C a r P r o d u c t i o n

INSPECTION / SHIPPING

M a n u f a c t u r i n g P r o c e s s O v e r v i e w V i d e o

M a n u f a c t u r i n g p r o c e s s o v e r v i e w v i d e o.

Manufacturing Process Overview Video

P o w e r U n i t C r a f t s m a n s h i p

P o w e r u n i t c r a f t s m a n s h i p.

Introducing the care and craftsmanship that go into every unit made.

T o y o t a P r o d u c t i o n S y s t e m

The Toyota Production System helps produce vehicles in a timely manner.

You Can Visit These 5 Toyota Manufacturing Plants

Toyota wants you to see exactly what goes into making their vehicles at one of their five Toyota Experience Centers in North America!

You Can Visit These 5 Toyota Factories

Toyota Motor Sales, U.S.A., Inc.

Toyota Experience Center

Have you ever wondered what goes into building your vehicle? Most of us only see them after they are assembled, shiny and new at the dealership. Now, curious minds can get a look at advanced manufacturing and Toyota North America’s past, present and future at five different experience centers at Toyota vehicle plants across North America! Read on to learn where your closest experience center is located and what it has to offer.

Blue Springs, Mississippi

Advertisement

Interactive light display projected onto specially painted matte gray Corolla

The 15,000-square-foot Toyota Mississippi Experience Center opened last June and was designed and built with a collaborative learning/training environment in mind. It has limited hours from 8 a.m. to 2 p.m., Tuesday through Thursday, so plan accordingly.

Here, you can experience an interactive light display that’s projected onto a specially painted matte gray Corolla, and try your hands at actual dexterity exercises used in Toyota training processes. The center’s patio overlooks the marshaling yard, where Corollas are parked, sorted and loaded every day before the vehicles are transported to their new homes.

Princeton, Indiana

The exhibition showcases the Floating Tundra display which relationship of parts coming together to make the vehicle.

This facility, which originally opened in 2009 and reopened in September 2022, boasts a truly cool floating Tundra display that will be a hit with those of all ages. This exhibition, which is held in place with stainless steel aircraft cable, showcases the relationship of all the parts that must come together to make a vehicle. It took a six-person team six months to assemble and suspend the display! The Toyota Indiana Experience Center is open to the public from 8 a.m. to 2 p.m. on Tuesdays, Wednesdays and Thursdays.

San Antonio, Texas

One of the more popular exhibits allows visitors to test a virtual paint sprayer.

Have an interest in pickup trucks ? Own a Toyota Tundra ? Toyota Texas is the only place in the world where Tundras are built, and a new one rolls off the line about once a minute!

The Experience Center offers hands-on exhibits on the fundamentals of building the Sequoia and Tundra vehicles. Guests can even test a virtual paint sprayer, experiencing what it's like to paint a Tundra using VR technology. The Toyota Texas Experience Center is open to the public from 8 a.m. to 2 p.m., Tuesday through Thursday.

Georgetown, Kentucky

Special exhibit breaks down the manufacturing process into each step, which gives visitors an up-close look at how Toyotas are built.

Toyota Kentucky is the oldest and largest facility in North America, and started tours in 1990. At the Experience Center, you'll find interactive displays and 3D projected maps that delve into Toyota's advanced production processes. You'll learn about the company's history and unique manufacturing process. One exhibit breaks down that process into each step, giving visitors a unique look at how Toyotas are built and how the company's process is different from other car manufacturers.

This center shares the same hours as the others, only open on Tuesdays, Wednesdays and Thursdays.

Ontario, Canada

Manufacturing Exhibit allows guests to complete activities inspired by new team member training stations.

Finally, if you live in or are visiting Canada, you can learn about how Toyota trains its new employees by completing activities inspired by new team member training stations. These activities are focused on dexterity, speed and accuracy, and are simulations of what you'd find in an assembly shop.

This Experience Center offers different hours than the others and is open to the public from 8 a.m. to 4:30 p.m., Monday through Thursday.

Save on your monthly payments! Find the best local prices on your next car.

U.S. News Best Cars Awards

- Best Cars for the Money

- Best Cars for Families

- Best Vehicle Brands

Recommended Articles

Cars Features

Dodge Charger Daytona

Caroline Anschutz Nov. 20, 2023

Ford F-150 vs. Ford F-250: Head-to-Head

Warren Clarke Nov. 17, 2023

How Much Do EVs Pollute?

Caroline Anschutz July 21, 2023

Why Are EVs Clogging Dealer Lots?

Kristin Shaw July 21, 2023

Tesla Cybertruck Fits In Your Garage

Kevin Williams July 21, 2023

Porsche to Offer 700 HP Cayenne PHEV

Jim Motavalli July 20, 2023

A Detailed Look At Toyota’s San Antonio Plant, Company's First Truck Plant In North America

What's the significance of the San Antonio Plant to Toyota's operation?

Early in January 2022, Toyota announced that it will be cutting production at its San Antonio plant by up to 50%. This came as a bit of surprise given that the San Antonio Plant is one of the most technologically advanced and flexible automotive manufacturing facilities in the world. The automaker said that the move is in response to the COVID pandemic.

Even so, the plant isn't anticipating any layoffs and is instead offering voluntary separations. The San Antonio plant is Toyota's first U.S. manufacturing facility outside the state of Kentucky, and it's also the automaker's first truck plant in North America.

But, even with the production cuts, Toyota Motor Manufacturing Texas (TMMTX) plant still remains an important part of the automaker's North American operations. It is the only place where the Toyota Tacoma and Tundra are assembled. The San Antonio plant is also a key cog in Toyota's North American supply chain.

Here's a look at the plant and what it produces.

What Does Toyota Build In The San Antonio Plant?

Located just outside of San Antonio, Texas, the 2.2 million-square-foot facility began production in 2006. The plant is home to a number of Toyota's most popular vehicles and produces an average of 208,000 units annually.

Here's a breakdown of the vehicles that San Antonio plant produces:

Toyota Tacoma: The Tacoma is Toyota's best-selling vehicle in North America , and it is assembled exclusively at the San Antonio plant. The midsize pickup truck was completely redesigned for the 2016 model year, and it continues to be a big seller for Toyota.

Toyota Tundra: The Tundra is Toyota's full-size truck . It, too, is assembled exclusively at the San Antonio plant. The Tundra was last redesigned for the 2014 model year, and it remains a key part of Toyota's truck lineup. TMMTX produces around 750 tundras a day.

Toyota Highlander: The Highlander is a large SUV that seats up to eight passengers. It is assembled at the San Antonio plant, as well as at Toyota's plants in Princeton, Indiana and Fukuoka, Japan.

Toyota Sienna: The Sienna is Toyota's minivan. It, too, is assembled at the San Antonio plant as well as at Toyota's plant in Princeton, Indiana.

Toyota Sequoia: The Sequoia is Toyota's largest SUV. It's the newest Toyota model to be assembled at the San Antonio plant, starting production in late 2016 .

Related: 10 Cool Mods For Your Toyota Tundra

How much do toyota plant workers make in san antonio.

TMMTX has a total of 3,200 full-time employees as of May 2022. The average hourly pay for an Assembly Line Worker at Toyota Motor Manufacturing Texas, Inc. was $14.85. This translates to a weekly pay of $594, a monthly salary of $2,574 and an annual salary of $33,060 .

This is slightly below the average yearly salary for all assembly line workers in the United States, which was $35,790 as of May 2022.

In comparison, the average pay for all workers at Toyota's Georgetown, Kentucky plant was $24.75 per hour while the Princeton, Indiana plant had an average hourly pay of $23.50 as of September 2017.

The slightly lower pay at the San Antonio plant may likely be because Texas is a right-to-work state. This means that workers can't be required to join a union as part of their employment. Texas is one of 28 states with this law. Also, the cost of living in Texas is lower than in some other states.

To make up for the lower starting wage, Toyota offers its San Antonio plant workers a production bonus. The bonus is based on how many vehicles the workers produce and can amount to several hundred dollars each week.

Related: 15 Great Cars You Can Own On A $50K Salary

What Has Been Toyota's Impact On The San Antonio Economy?

Since beginning production in 2006, the Toyota San Antonio plant has had a $2.7 billion economic impact on the city of San Antonio and Bexar County, according to a study done by the University of Texas at San Antonio's Institute for Economic Development. This includes the creation of 16,500 direct and indirect jobs.

The plant has also been a boon to the local suppliers. There are now more than 30 suppliers located near the plant, providing parts and materials to TMMTX. This is up from just six suppliers when the plant first opened.

The Toyota San Antonio plant has also helped to attract other Japanese companies to the city. More than 20 Japanese companies have located facilities in San Antonio since Toyota announced its plans to build the plant.

These companies have brought an additional $2.7 billion in investment to the city and created thousands of jobs.

While production is being cut back in the short-term, Toyota remains committed to the San Antonio plant and the city of San Antonio. The company plans to eventually increase production at the plant once demand for its vehicles improves. For now, the plant will continue to build the Toyota Tacoma, Tundra, and Sienna.

Are you signed up for the Tuesday Business Report?

This new weekly digest of our business and development reporting is your must-read newsletter for local business news.

San Antonio Report

Nonprofit journalism for an informed community

Toyota rolls out new hybrid Sequoia SUV at San Antonio plant

Share this:

- Click to email a link to a friend (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Twitter (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Reddit (Opens in new window)

Toyota’s $391 million upgrade to its San Antonio plant culminated Wednesday in the rollout of its redesigned 2023 Sequoia, a full-sized hybrid SUV to be manufactured entirely at its plant on the South Side.

The plant, which has the capacity to produce 200,000 vehicles a day, will exclusively make the Tundra truck and Sequoia, which replaced the smaller Tacoma pickup line made at the site before its production was moved earlier this year to Mexico.

Toyota Motor Manufacturing Texas commemorated the rollout in a showroom event on Wednesday. Mayor Ron Nirenberg and Bexar County Judge Nelson Wolff, as well as state Rep. John Lujan (R-San Antonio) helped mark the occasion.

In a brief speech, Nirenberg said the event was about more than a new vehicle. “This is another welcome milestone demonstrating Toyota has confidence in our city and in our workforce,” he said.

“Manufacturing is the future of San Antonio,” Wolff said, highlighting Toyota’s role in attracting suppliers and helping establish Texas FAME apprenticeship program , which seeks to develop San Antonio’s manufacturing workforce. “None of this would have occurred without Toyota making its decision to come here in 2003.”

Toyota’s entry into San Antonio in 2003 sparked the region’s transformation into an auto manufacturing hub. Some 3,800 Toyota employees work at its San Antonio campus, joined by roughly 5,300 employees for nearly two dozen on-site suppliers, according to the company.

In 2019, Toyota announced it was spending $391 million — bringing its total investment in the plant to more than $3 billion — to upgrade the assembly lines in San Antonio, which paved the way for the Tundra and Sequoia to be built exclusively in Texas. Toyota’s suppliers and other automotive manufacturers followed with their own announcements of new investments.

A year ago, Aisin AW, which makes automatic transmissions, opened a $400 million plant in Cibolo. Continental Structural Plastics, a subsidiary of Japan-based Teijin Automotive Technologies , built a composites manufacturing plant in Seguin, where it manufactures components for Toyota Tundras.

In 2019, heavy-duty truck manufacturer Navistar announced plans to build a $250 million plant in San Antonio . Last year it expanded that investment, and the plant became operational this year.

A 2019 report commissioned by Greater:SATX estimated that Toyota’s investment and ripple effect with suppliers would deliver around 40,000 total jobs and $10 billion in economic impact to the region over a 10-year period.

Toyota’s recent transformation of its plant allows it to use new laser welding technology and a new production process that stamps out “the largest sheet of metal in Toyota history,” according to the company.

Toyota Texas President Kevin Voelkel said the Sequoia would be the largest SUV offered by the company.

“Every time you see a Sequoia or Tundra on the road, I hope you feel the same sense of pride I feel knowing these trucks were born in Texas and built by Texans,” he said.

Toyota introduced the Sequoia in 2000 as the first Japanese-made full-size SUV. The vehicle was previously manufactured at Toyota’s plant in Princeton, Indiana. The upcoming model year, marking its third generation, is the first time the line will be sold as a hybrid, and is available only as a hybrid.

Last year more than 8,000 Sequoias were sold in the U.S., according to year-end sales figures.

The 2023 Sequoia, which starts at $58,000, will be offered at dealerships beginning next month.

More from San Antonio Report

San antonio’s week in photos, march 24-30, where i work: sa digital connects, texas could require social media influencers to disclose paid political posts, waylon cunningham.

Waylon Cunningham covered business and technology for the San Antonio Report. More by Waylon Cunningham

- Forum Listing

- Marketplace

- Advanced Search

- Toyota Nation Forums

- Toyota News

Toyota Texas Assembly Named Best Factory Tour

- Add to quote

I should go check it out. I live about 40 miles from that plant.

^^Make sure you drive your Honda there:lol::lol::lol:

MEH. I'll take the GMC. Jeff - I went through the Bowling Green plant a few years back.

To each his own, but I personally would prefer to take tour of this plant: I wish I would have had the time to stay in BG another day to take the tour when I was there visiting the Museum in May. Someday I will go back.

- ?

Ask a question

- 589.1K members

Top Contributors this Month

- Takata Recall

- Crown Signia

- Grand Highlander

- Land Cruiser

- Concept Vehicles

- Historic Vehicles

- CALTY 50th Anniversary

- 2024 Toyota Land Cruiser

- 2024 Toyota Tacoma

- New Product Showcase

- Los Angeles

- Global Shows

- What’s New for 2025

- What’s New for 2024

- What’s New for 2023

- What’s New for 2022

- Images & Videos

- Latest News

- Sales & Financial

- Voluntary Recalls

- Takata Info

- Environmental

- Community Engagement

- Diversity & Inclusion

- Finance, Insurance & Banking

- Advanced Technology

- Research & Development

- Safety Technology

- Motorsports

- Company History

- Executive Bios

- Media Contacts

- Add to Cart

- Convert to PDF

Home > Corporate > Manufacturing

Toyota’s U.S. Manufacturing Footprint: Impacting Communities with Innovation and Respect

For more than 60 years, Toyota has been a part of the cultural fabric in the United States, establishing communities centered around manufacturing in cities across North America. In fact, many of the people driving Toyota cars and trucks in these areas often have a good idea about who had a hand in assembling them.

“Our family members are the customers,” says Norm Bafunno, senior vice president of Unit Manufacturing and Engineering at Toyota Motor North America (TMNA). “And there’s nothing more rewarding than hearing feedback from them about the Toyotas they’re purchasing and knowing we had a part in that. It’s a source of great pride.”

Today, Toyota operates 14 manufacturing plants in North America, and employs more than 32,000 people to design, engineer and assemble almost half of the vehicles Toyota sells in the United States. By manufacturing in North America, Toyota supports regional suppliers and economies, fosters local communities and assembles high-quality cars and trucks for customers. Toyota’s commitment to assembling vehicles where they are sold not only benefits the areas surrounding local plants, but also helps the company better understand its customers.

“I think that pride in manufacturing resonates within our plants and creates products that will exceed customer expectations,” Bafunno says. “Manufacturing where we sell is what we need to do to be successful in the marketplace.”

Each TMNA manufacturing plant benefits the local economy directly by creating new jobs for people in the region. But according to Bafunno, throughout his career, he’s witnessed firsthand how the manufacturing plants establish and cultivate a sense of community spirit that employees carry with them well beyond the campus grounds.

“During my 24 years at Toyota, I’ve watched manufacturing evolve,” Bafunno says. “I was at the third assembly plant built. As I’ve watched us grow, what I’ve noticed the most is our impact on the lives of people.”

Creating Community

A Toyota plant creates a whole ecosystem within a region, according to Brian Krinock, senior vice president of Vehicle Plants, TMNA. Krinock, who has been with Toyota for 30 years, has spent time at almost every manufacturing plant built in North America. He says that when you factor in the size of each plant — between 400 to 9,000 employees — and include the families of each employee, contractor and supplier, it exponentially increases the number of people in a community impacted by Toyota.

“The impact we have in a community is huge,” Krinock says. “We want to be a good citizen wherever we do business, because we live there, our families are there, and it is important to us to be a part of our communities.”

Krinock believes that much of this attitude stems from Toyota’s company values, which each employee takes to heart both in the workplace and beyond.

“We’re all about our values, ‘Respect for People’ and ‘Continuous Improvement,’” Krinock says. “Having strong values is the most important part of a company culture, and we’ve really fostered that throughout Toyota.”

Toyota employees often volunteer to lead nonprofit boards that provide needed services, such as donating and delivering to food pantries and crisis centers. But while Toyota supports employee groups and fundraisers like Relay for Life and Susan G. Komen’s Race for the Cure, Bafunno says people are quick to help their fellow colleagues and families beyond those organized events — and he’s seen more examples than he can count.

“I find that the communities we are a part of recognize who we are not by some great commercial or someone’s great speech, but by the actions our employees take every day in the community,” Bafunno says. “When a family’s world gets disrupted by some terrible event, our employees step up to contribute. It makes you incredibly proud to be a Toyota employee.”

Continuous Improvement, Across the Board

In addition to charitable work, when employees embrace Toyota’s values, it often leads to innovation, learning and discovery of new ways to get things done on the job. Both Bafunno and Krinock believe that everyone in the organization can embody the culture of “Continuous Improvement,” no matter what they do at Toyota.

“Part of the participation in Toyota goes well beyond the normal job,” Bafunno says. “It goes into using your knowledge and experience to make things better — and that goes for everybody in the organization. It’s a fundamental part of our process.”

For example, someone in manufacturing may assemble a nut and bolt in a way that makes it more efficient to grab on the line, or an engineer may improve the way a project is sourced to make it less expensive. Many employees’ proposals build off one another and become incredible innovations over time. Plus, some Toyota employees have even patented their great ideas.

“I want everyone to know that our people are the biggest asset we have,” Krinock says. “Ideas come from the floor, come from the middle to the top of the company all the time. Everyone at Toyota has the ability to change what we do each and every day.”

Building a Sustainable Way Forward

Many of the innovations and ideas that come from employees have to do with sustainability. As Toyota works to reduce waste and make improvements to reach carbon neutrality, its manufacturing plants are doing their part.

“Believing in sustainability is ‘Respect for People,’” Krinock says. “One, because we need to respect our communities. But also, we respect the people who come up with better ideas and empower them to make changes. Our best sustainability ideas come from someone on the floor who says, ‘Hey, why are we doing this this way? Why are we using cardboard? Can we deliver this differently?’”

There’s a misconception that manufacturing, an industry that assembles and creates things, isn’t focused on sustainability, but Bafunno thinks that people would be surprised about the processes that are already in place at each of Toyota’s plants. Almost all plants have established eco zones, which are on-site natural habitats. There are policies to lower water consumption, curb emissions and reuse plastics. In addition, Toyota has some of the first zero-landfill manufacturing facilities in the country. And that’s just the beginning.

“When it comes to sustainability, we have a lot of change coming,” Bafunno says. “It’s a big priority for us. Each of us has these strong pillars of responsibility because it creates job security. If we sit still, our competition is going to blow by us, and we’ll lose some of that stability if we’re not in a leadership role.”

Within the manufacturing team, there’s a strong understanding of the idea of “Continuous Improvement” and a push for more innovation. Both Krinock and Bafunno believe that within the automotive industry, the next few years are going to be transformative — and full of excitement.

“I’ve been in the industry for 36 years,” Krinock says. “The change we’re seeing in automotive right now is like we’ve never seen before. We’re changing the technologies and materials, electrifying our vehicles, updating structures of the vehicle itself and using more recyclable products. Going forward, it’s only going to continue to evolve — and Toyota will be a part of that.”

Tracing Toyota’s U.S. Manufacturing Journey

From its modest beginnings selling just 288 vehicles in 1957, Toyota has been etched into the U.S. cultural fabric for more than 60 years. Here in our backyard, Toyota contributes to world-class design, engineering and assembly of vehicles. Toyota continues to expand its U.S. operations and investment in local communities, while innovating for a better world.

10 U.S. manufacturing plants 1

Hover over the map to explore Toyota's U.S. manufacturing footprint.

Toyota Motor Manufacturing, Texas

Toyota Motor Manufacturing, Missouri

Toyota Motor Manufacturing, Indiana

Toyota Motor Manufacturing, Kentucky

Toyota Motor Manufacturing, West Virgina

Toyota Motor Manufacturing, Tennessee

Toyota Motor Manufacturing, Mississippi

Mazda Toyota Manufacturing

Toyota Motor Manufacturing, Alabama

Toyota Battery Manufacturing, North Carolina

Years manufacturing in the U.S. 2

Employees 3

Vehicles assembled and counting 4

Direct investment in the U.S.

Toyotas assembled 5 and exported to 40 countries

Funds donated to U.S. communities and causes

Vehicles sold in 2020

Vehicles assembled in 2020

Employee volunteer hours invested in 2020

Hybrid models sold in the U.S. 6

Gallons of water recycled or reused 7

Pollinator gardens supporting monarch butterflies' migration

Originally published October 5, 2021

Related Stories

Test Your Knowledge of the CALTY Design Research Studio’s 50-Year History

Test Your Knowledge of the 2023 Toyota Sequoia

New Toyota Production Line Boosts Hybrid Vehicle Capabilities

Email sign up.

Enter your email address below to sign up for email alerts.

* Indicates Required

Thank you for subscribing. Please check your email to validate your sign up.

You are already subscribed, your mailing lists have been updated.

Copyright Notice

All materials on this site are for editorial use only. The use of these materials for advertising, marketing or any other commercial purpose is prohibited. They may be cropped but not otherwise modified. To download these materials, you must agree to abide by these terms.

IMAGES

COMMENTS

US plant tours are available exclusively for education groups. To schedule a tour, please contact us at: Blue Springs, MS - [email protected]. Georgetown, KY - [email protected]. Princeton, IN - [email protected]. San Antonio, TX - [email protected].

The tour begins in the education pavilion with a short video of the Toyota history. One thing I might mention is that once the tour starts you will not come back to the education center as you drive your own car to the main plant where the tour begins and we left from there. The factory tour was very interesting and lasted about a full hour.

Toyota Motor Manufacturing, Texas, Inc. (TMMTX) 9,400. Employment 27. 9,400. ... Deep in the heart of our leading-edge San Antonio manufacturing facility, you'll find 2,600 Toyota team members proudly building some of the toughest trucks on the road: ... Toyota Plant Tours; Help

A recent tour of the Toyota Motor Manufacturing Texas plant really showed how well the Tundra and Tacoma are built. The TMMTX plant sits on the south side of San Antonio, Texas and really does occupy an old ranch (the 1794 moniker comes from this). It sits upon 2,000 acres of land and outside of the 2 million square-foot plant there are still ...

By Gordon White. Posted on May 30, 2017. Truck Camper Magazine tours the Toyota Motor Manufacturing Texas (TMMTX) plant in San Antonio, Texas. See truck bodies grabbed by Godzilla and Tacomas and Tundras made by man, machine, and a precision-guided fleet of roving robots. In the spring of 2014, we contacted Toyota Motor North America to request ...

5 reviews and 16 photos of Toyota Motor Manufacturing Visitor Center "Going to start off by saying, I may be a little bias. I'm a huge Toyota fan, we've been a Toyota family, and yes, I'm one of "those guys" that has a name for my Tundra . Been wanting to come check out "the Mecca" for a while now, to see how these amazing vehicles are made, and boy, did this place not disappoint.

The second critical factor for choosing San Antonio as a site for the new Tundra plant was the availability of a large pool of qualified workers. San Antonio is the eighth-largest city in the U.S. and the second-largest in Texas. Toyota received more than 100,000 applications for the 2,000 high-paying manufacturing jobs.

Great Tour - Review of Toyota Motor Manufacturing - TMMTX Experience, San Antonio, TX - Tripadvisor. Toyota Motor Manufacturing - TMMTX Experience - CLOSED. 1 Lone Star Pass, San Antonio, TX 78264-3638. Save.

Nokona has been making made in the USA baseball gloves in Nokona, Texas since 1934. See every part of the baseball glove making process from leather selection to cutting, stamping, embroidery, forming, stitching, and lacing on this Texas factory tour. I'd rather take a bucket of worms and go fishing than import Nokona gloves. Visit the ...

The wonders of Toyota's vehicle production come to life through a virtual plant tour. Go behind the scenes of the entire production process and experience the care, craftsmanship and innovation that go into every Toyota vehicle. ... made up of some 30,000 parts - all filled with care and craftsmanship in every step of production People are the ...

Toyota Motor Manufacturing Texas (TMMTX) is an automobile manufacturing factory in San Antonio, ... assembly plant into an automotive production site including several on-site suppliers which shipped directly to the factory. In addition, Toyota announced that production capacity, originally planned for 150,000 units per year, would be expanded ...

Georgetown, Kentucky. Toyota Motor Sales, U.S.A., Inc. Special exhibit breaks down the manufacturing process into each step, which gives visitors an up-close look at how Toyotas are built. Toyota Kentucky is the oldest and largest facility in North America, and started tours in 1990. At the Experience Center, you'll find interactive displays ...

The Toyota Motor Manufacturing, Texas, Inc. plant in south Bexar County is seen in this Jan. 18, 2013 aerial photo. The TMMTX plant, announced in 2003, now builds Tundra and Sequoia pickup trucks.

TMMTX has a total of 3,200 full-time employees as of May 2022. The average hourly pay for an Assembly Line Worker at Toyota Motor Manufacturing Texas, Inc. was $14.85. This translates to a weekly pay of $594, a monthly salary of $2,574 and an annual salary of $33,060.