- AIR DEFLECTORS

- LIGHTHOUSE PROTECTIONS

- SUPPLEMENTARY LIGHTS

- WINDSCREENS

- ACCESSORIES

- COLLECTORS AND DECATS

- COMPLETE EXHAUST SYSTEM

- HEATSHIELDS

- STICKERS AND PLATES

- SUPPORT BRACKETS

- FORK PISTON KIT

- FORK SPRINGS KIT

- SHOCK ABSORBER OIL

- SHOCK ABSORBERS

- SHOCK SPRINGS

- STEERING DAMPERS

- UPGRADE KIT

- ADJUSTMENTS & ADAPTERS

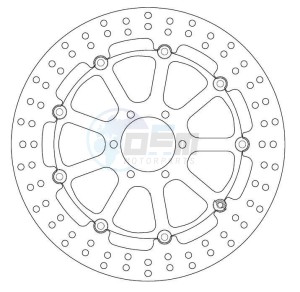

- BRAKE DISCS

- BRAKE LINES

- BRAKE/CLUTCH LEVERS

- MASTER CYLINDERS

- BATTERIES STANDARD

- BATTERY CHARGERS

- GEAR INDICATOR

- HANDLEBAR SWITCHES

- HOUR METERS

- INSTRUMENTS

- LAPTIMER / DASHBOARDS

- LIGHTS & INDICATORS

- LITHIUM BATTERIES

- QUICK SHIFTER

- TRACTION CONTROL

- CARBON WHEELS

- FORGED ALUMINIUM

- FORGED MAGNESIUM

- RIMS VALVES

- FRAME SLIDERS

- HALF-HANDLEBARS

- SPARE PARTS PLATFORMS

- THROTTLE CONTROLS

- TRIPLE CLAMPS

- AIR FILTERS

- ENGINE GUARDS

- INTAKE PARTS / SUCTION

- REED VALVES

- THROTTLE BODIES

- WATER PUMP KIT

- ENLARGED RADIATORS

- RADIATOR COVERS

- SILICONE HOSES

- AUTOMATIC CLUTCHES

- CLUTCH DISCS

- CLUTCH LINES

- CLUTCH MASTER CYLINDERS

- CLUTCH SLAVE CYLINDERS

- PRESSURE PLATE

- SLIPPER CLUTCHES

- SPARE PARTS

- STANDARD CLUTCHES

- CHAIN ADJUSTER

- REAR SPROCKET AND PINION

- SCOOTER TRANSMISSION

- LICENSE PLATE SUPPORT

- MOTORBIKE COVERS

- NAVIGATOR SUPPORTS

- SEAT COVERS

- TOP CASE/PANNIERS

- FRAME PROTECTIONS

- TYREWARMERS

- BRAKE/CLUTCH FLUID TANKS

- CLUTCH COVERS

- ENGINE OIL FILLER CAPS

- ENGINE SCREWS KIT

- FAIRING SCREWS KIT

- FLUID TANK CAPS

- FRAME PLUGS

- FRAME SCREWS KIT

- REAR SPROCKET FLANGE

- SPROCKET COVERS

- TAPPI RUOTA

- WHEEL BOLTS

- WINDSCREEN SCREWS KIT

- CARBON PARTS

- MTORBIKE CARES

- WORKSHOP EQUIPMENT

- USED SHOWCASE

- SWEATSHIRTS

- PROTECTIONS

- VISORS AND ACCESSORIES

- BRAKE HOSES

- BRAKE LEVERS

- DISCS AND PADS

- IGNITION AND CONTROL UNITS

- INSTRUMENTATION

- COMPLETE ENGINE KITS

- CRANKSHAFTS

- CYLINDER HEADS

- ENGINE CRANCKASE

- ENGINE VALVES

- EXHAUST SYSTEM

- GAS VALVE SPRINGS

- OIL LEVEL DIPS

- ROLLER CAGES

- ROLLER SHELLS

- THERMAL GROUPS

- CARBURETOR KITS

- CARBURETORS

- INTAKE MANIFOLDS

- OIL AND FUEL FILTERS

- OIL FOR AIR FILTERS

- POWER SUPPLY KIT

- FORK CLAMPS

- OIL SEALS AND DUST SEALS

- SHOCK ABSORBER SPRINGS

- SHOCK ABSORBERS AND FORKS

- CRANKCASE COVERS

- DRIVE ROLLERS

- PINS AND HUBS

- TORQUE CONTROLLERS AND PULLEYS

- TORSION CONTROLLER

- GAS CABLES AND FUEL HOSES

- LEVER CONTROLS

- SILENT BLOCK

- WHEEL SPACER

- All manufacturers

- Tre 1130 K Amazonas

BONAMICI RACING ADAPTOR FOR STANDARD LEVER PROTECTION 15-16 MM

Remote adjuster racing for bonamici racing lever 77,5mm, remote adjuster racing for bonamici racing lever 52,5mm, remote adjuster standard bonamici racing for bonamici racing lever 77,5mm, remote adjuster standard bonamici racing for bonamici racing lever 52,5mm, bonamici racing pair of half handlebars 50mm universal, bonamici racing universal pair of racing evo stand support, bonamici racing universal pair of standard evo stand support, bonamici racing universal evo clutch lever protection, bonamici racing universal evo brake lever protection, excel spoked rear wheel benelli tre-k amazonas with disc and tire, pair of excel spoked rims benelli tre-k amazonas with discs and tires, dna cotton air filter benelli tre-k 1130 2007-2010, bonamici racing carbon lever protection adapter for 20-21mm handlebars, bonamici racing carbon lever protection adapter for 19-20mm handlebars, bonamici racing carbon lever protection adapter for 18-19mm handlebars, bonamici racing carbon lever protection adapter for 17-18mm handlebars, bonamici racing carbon lever protection adapter for 16-17mm handlebars, bonamici racing carbon / evo lever protection adapter for 15-16mm handlebars, bonamici racing carbon / evo lever protection adapter for 14-15mm handlebars, bonamici racing carbon / evo lever protection adapter for 13-14mm handlebars, bonamici racing universal carbon brake lever protection without adaptor, bonamici racing brake adjuster connection for brembo 19x20, replacement footpeg racing 82mm not threaded for bonamici racing rearboards.

- Tornado 900

- TNT Titanium

- Pepe 100 Lx

- Leoncino 250

- Tornado Tre 1130

- Tornado Naked Tre Sport Evo

- TNT Cafè Racer

- Velvet 250 Eco

- Velvet 150 Eco

- Velvet 125 Eco

- Tornado 900 Tre

- Leoncino 500

- TRK 502 / X 2017-2024

- BN 251 2016-2020

- 502 C 2019-2024

- 752 C / S 2019-2024

- Leoncino 800

- LEONCINO 125

- IMPERIALE 400

- Tornado Naked Twin 500 2023-2024

- TRK 702 / X 2023-2024

Save products on your wishlist to buy them later or share with your friends.

- Advice & Inspiration

- Track an Order

- Return an item

- Create an account

- Accessories

- Klarna Klarna available at the checkout

- Over 250,000 Products £14m+ stock holding

- Next-day Delivery Available 7 Days a Week

- Click & Collect From a shop near you

- Pay later with Paypal Pay within 4 or pay in 3 available

- 15+ Years Online Tried, tested, trusted

- Benelli Tre-K 1130

- Price Range £7 - £187 Price Range Simply drag the slider bar to set your price range.

- Dynavolt (1)

- Hiflo filtro (1)

- R&G Racing (3)

- Renthal (1)

- View More (3)

- Product Type

- Batteries (1)

- Bodywork (2)

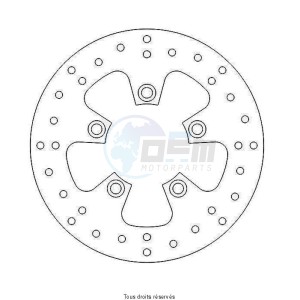

- Brake Discs (4)

- Brake Pads (12)

- Crash Protectors (1)

- Luggage Accessories (1)

- Luggage Fitting Kits (3)

- Oil Filters (1)

- Spark Plugs (2)

- View More (1)

Benelli Tre-K 1130 Parts & Accessories

model fitment

MOTORCYCLE ACCESSORIES AND SPARE PARTS

- Brake discs 1

- Brake pads 3

- License plate 1

- Motorcycle batteries 2

- Quickshifters 1

- Flanges and accessories for tank bags 1

MOTORCYCLE BRAND AND MODEL

- Cafe Racer 1130 - 2007/2008 1

- TNT 1130 - 2005/2008 1

- TNT 899 S/T - 2008 1

- TNT Sport 1130 - 2007/2008 1

- TNT Titanium - 2007/2008 1

- Tornado Tre 1130 - 2007/2008 1

- Tornado Tre 900 - 2007/2008 1

- Tornado Tre 900 RS - 2007/2008 1

- Trek 1130 - 2006/2009 10

Manufacturers

- Accossato 0

- All-Balls 0

- Barracuda 0

- Bike-Lift 0

- Blackbird Racing 0

- Braking (E23) 0

- Braking (E28) 0

- Braking (Epta Racing) 0

- Brembo Racing 0

- CNC Racing 0

- DT1 Air Filters 0

- Dynojet - Power Commander 0

- Fren Tubo 0

- GB Racing 0

- LabelBike 0

- Lea Components 0

- Lightech Carbon 0

- Motomaniashop 0

- Powerbronze 0

- Quattroerre 0

- Racing Bike 0

- Rapid Bike 0

- Rizoma Stealth 0

- SP Connect 0

- Sprintfilter 0

- Steelbike 1

- Tommaselli 0

BREMBO GENUINE BRAKE REAR PADS SET 07BB2065 BENELLI TREK 1130 2006-2009

Brembo serie oro rear brake disc benelli trek 1130 2006-2009, brembo sintered brake rear pads set 07bb20sp benelli trek 1130 2006-2009, givi flange for attaching bags tanklock tank benelli, healtech electronic quickshifter kit for benelli trek 1130 2006-2009, high power battery furukawa ftz14-bs benelli trek 1130 2006-2009, license plate holder for benelli trek 1130 2006-2009, adjustable in aluminum, pair of brembo serie oro floating front brake discs benelli trek 1130 2006-2009, sintered rear brake pads set sbs 730 ls benelli trek 1130 2006-2009, skyrich hjtz14s lithium battery benelli trek 1130 2006-2009 (for europe only).

- EUR EUR USD GBP AUD CAD NZD

parts and accessories for Benelli Trek 1130 TK 2007-2017

More universal products that fit your model Benelli Trek 1130 TK 2007-2017

Declaration of production articles and exclusion from revocation

Steel braided hoses are not stock items, but production items. They are only produced and pressed firmly at your request with your selected colours and fittings. We exclude these articles from revocation in accordance with the applicable law ( take a look Cancellation-Instructions ) and refer to § 312g Para. 2 BGB (German Civil Code).

On working days the production takes place on the same day and we are anxious to dispatch it also on the same day. As a rule, orders received before 14:00 are picked, pressed, packed and dispatched on the same working day.

No liability is accepted for damage caused by improper installation. Modifications to the lines are not permitted and therefore lose your operating licence.

Your team from MTP-Racing

Aftermarket BENELLI / TRE-K 1130

Do you want to search on OEM parts Click here

Spark plug CR9EB

Tyre 120/70-17 58W TL SPORTEC M3 FRONT Avant

Battery Ytz14s-bs - Ss Entr. AGM L 150mm W 87mm H 110mm 12v 11.2ah Acid 0.54l

Ball bearing 30x55x13 - 2RS/C3

Brakepad Sinter metal Sinter Grip Road

Brake Disc Floating YAMAHA - Approval TÜV Ø External: 320mm, ØInternal: 64mm, Thickness: 5mm, No mounting holes: 6, Ø diam: 8.5mm, Ø Diam int: 80mm, Offset: .0mm

Spark plug CR9EIX

Lever Brake Benelli - Yamaha OEM: 5ch-83922-00

Tyre 180/55 ZR 17 SPORTMAX QUALIFIER 2 73W TL Rear

Tyre Michelin Pilot Pilot Road 4 MIC103565 + MIC694117

Brake disc fixed BMW - with homologation TUV

Battery Lithium HJTZ14S-FP-S - (YTZ14S-BS)

Tyre 180/55-17 73W TL GPR300

Oil Fiter Adaptable BENELLI - Equal to HF553 Ø External: 65mm, Length: 65mm, Color: Black, Qty:

Chainwheel Steel Benelli - 525 - 36 Teeth- Made in Germany

Battery Ytz14s-bs SLA-AGM - Without Acid. Ready to Use

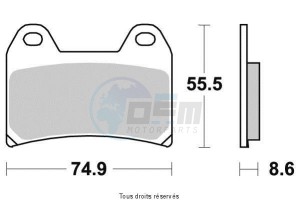

Brake Pad Sifam Sinter Metal S1110N

Brakepad Organic Eco-Friction suitable for road use

Brake Disc Bmw Ø240x124X110 Mounting holes 6xØ6,5 Disk Thickness 5

Battery TTZ14-S - AGM L 150mm W 87mm H 110mm 12v 11.2ah Delivery with Acid

Brake Pad Kyoto Semi-Metal YAMAHA X-MAX 125 2006-2015

Spark plug CR9E-B1 BLISTER

Spark plug CR9E

Train Tyres Dunlop Roadsmart SPORTMAX ROADSMART DUN621254 + DUN621259

Train Tyres Metzeler RoadtecZ6 RoadtecZ6 MET1448100 and MET1448600

Lever Clutch Aprilia - Benelli - BMW - Derbi - Rieju - Yamaha

Ball bearing 6005-2RSH/C3 - SKF 25 x 47 x 12

Ball bearing 25x47x12 - 2RS/C3

Train Tyres Pirelli Diablo Diablo PIR1430700 and PIR1430000

Brake Pad Vesrah Sinter Metal VD262JL Length: 74.6 Width: 55.5 Thickness: 8.6 Length2: 0 Width2: 0 Thickness2: 0

Ball bearing 6006-2RS1/C3 - SKF 30 x 55 x 13

Tyre 120/70-17 58W TL GPR300F

Brake Pad Sifam Sinter Metal S1262N

Battery YTZ14-S - AGM L 150mm W 87mm H 110mm 12v 11.2ah

Oil filter BENELLI - Equal to HF553

Tyre 120/70 ZR 17 58W TL Front SPORTMAX QUALIFIER 2

Why choose OEM Motorparts?

- Easy online ordering

- All your spare parts from one supplier

- Shipped and Packed Professionally

Multiple payment options

We offer several payment options. Pay safely and securely with the payment method you are used to.

It's great that you are here!

Call or WhatsApp 786-242-5400 | Mon-Fri 9-5 EST

Benelli Tre 1130 K Parts

Do you need assistance with your order?

- FASHION ACCESSORIES

- MODEL SCALE

- New Discover!

Filter by price

- More than (20)

Showing 1-20 of 20 item(s)

- Not available

Filter Your Selection

Benelli shop, search for products.

Start typing to see products you are looking for.

- Benelli Manuals

- Workshop manual

Benelli TnT 1130 Workshop Manual

- Use and maintenance (47 pages)

- page of 392 Go / 392

Advertisement

Quick Links

Related manuals for benelli tnt 1130.

Summary of Contents for Benelli TnT 1130

- Page 2 P P P P P remise This manual contains an introductory description of the Benelli TnT together with the procedures for control/intervention and revision of the main components. Information considered generally noted is not included. This manual will help you to understand the motorcycle better in order to provide the client with a rapid and trustworthy service.

- Page 3 I I I I I ntroduction SYMBOLS The symbols listed below are all present inside the manual and serve to show those parts which need to be given special attention. ATTENTION - Be aware that you will find death or serious injury, in case the instructions are not observed.

- Page 4 1 1 1 1 1 GENERAL INFORMATION GENERAL INFORMATION GENERAL INFORMATION GENERAL INFORMATION GENERAL INFORMATION C C C C C ONTENTS VEHICLE IDENTIFICATION IMPORTANT INFORMATION SPECIAL INSTRUMENTS 1.3.1 SPECIAL ENGINE INSTRUMENTS 1.3.2 SPECIAL FRAME INSTRUMENTS 2 2 2 2 2 SPECIFICATIONS SPECIFICATIONS SPECIFICATIONS...

- Page 5 3.28 CONTROL AND REPLACEMENT TRANSMISSION COG-WHEELS 3.29 CHECKING AND ADJUSTING STEERING BALL-BEARINGS 3.30 CHECKING FORK 3.31 CHECKING DAMPER 3.32 ADJUSTING DAMPER 3.33 CHECKING TIRE PRESSURE 3.34 CHECKING WHEELS 3.35 CHECKING AND OILING CLUTCH CABLE 3.36 ELECTRICAL PLANT 3.36.1 CHECKING BATTERY 3.36.2 BATTERY RECHARGING SYSTEM 3.37...

- Page 6 5.3.2 CHECKING VALVES AND VALVE GUIDES 5.3.3 CHECKING VALVE HOUSINGS 5.3.4 CHECKING VALVE SPRINGS 5.3.5 CHECKING BUCKET-TYPE TAPPETS 5.3.6 MOUNTING VALVES CYLINDER 5.4.1 DISMANTLING CYLINDER CASING 5.4.2 CHECKING CYLINDER 5.4.3 DISMANTLING WATER COLLECTOR 5.4.4 CHECKING WATER COLLECTOR 5.4.5 MOUNTING WATER COLLECTOR 5.4.6 MOUNTING CYLINDERS PISTONS...

- Page 7 5.10.4 DISMANTLING OIL PUMP 5.10.5 CHECKING OIL SUMP 5.10.6 CHECKING OIL PUMP 5.10.7 ASSEMBLING OIL PUMP 5.10.8 MOUNTING OIL PUMP 5.10.9 MOUNTING OVERPRESSURE OIL VALVE 5.10.10 MOUNTING OIL SUMP 5.11 CASING 5.11.1 DISMANTLING CASING 5.11.2 DISMANTLING FREE WHEEL 5.11.3 DISMANTLING BALANCING COUNTER SHAFT 5.11.4 DISMANTLING ENGINE SHAFT 5.11.5...

- Page 8 REAR WHEEL, BRAKE DISK AND CROWN 7.2.1 REMOVING REAR WHEEL 7.2.2 CHECKING REAR BRAKE DISK 7.2.3 DISMANTLING REAR WHEEL 7.2.4 CHECKING REAR WHEEL 7.2.5 CHECKING HUB 7.2.6 CHECKING CROWN 7.2.7 MOUNTING REAR WHEEL 7.2.8 INSTALLING REAR WHEEL FRONT AND REAR BRAKES 7.3.1 REMOVING FRONT BRAKE PUMP 7.3.2...

- Page 9 BACK ARROW LAMP REPLACEMENT DIAGNOSTICS DIAGNOSTICS DIAGNOSTICS DIAGNOSTICS DIAGNOSTICS 10.1 ELECTRICAL PART 10.2 FRAME 10.3 AXONE2000 BENELLI INSTRUCTION MANUAL 10.3.1 GENERAL SAFETY PRECAUTIONS FOR OPERATORS 10.3.2 HOW TO USE AXONE2000 BENELLI CORECTLY 10.3.3 DESCRIPTION OF AXONE2000 BENELLI 10.3.3.1 KEYPAD MF13...

- Page 10 10.3.3.2 INTERFACE MODULE 10.3.3.3 READ/WRITE UNIT 10.3.3.4 INPUT/OUTPUT CONNECTORS 10.3.3.5 HOW TO POWER THE AXONE2000 BENELLI 10.3.3.6 RECHARGING THE BATTERY 10.3.3.7 REPLACING THE BATTERY 10.3.3.8 NOTES FOR CORRECT USE 10.3.3.9 TECHNICAL SPECIFICATIONS 10.3.3.10 SPARE PARTS 10.3.3.11 GLOSSARY 10.3.3.12 GETTING STARTED 10.3.3.13 STARTING PROGRAMS...

- Page 11 GENERAL INFORMATION G G G G G eneral I I I I I nformation ATTENTION/WARNING/NOTE Read carefully the manual and follow the instructions. To underline special information, the symbols and the words ATTENTION, WARNING and NOTE have specific meanings. Pay particular attention to the messages underlined with the following words and the corresponding signal.

- Page 12 WARNING WARNING AVVERTENZA * In case it will be necessary to replace parts, only use Benelli original spare parts or their equivalents * In case of disassembly of parts to be used again, dispose them in a tidy way in order to reassemble them in the right way and in the correct position.

- Page 13 5. Keep all the components away from any source of heat. • SPARE PARTS Use original Benelli spare parts exclusively. Use oils and greases recommended by Benelli to oil the components. Other products might appear similar in look and function but are inferior in quality. MF13...

- Page 14 1.3 SPECIAL INSTRUMENTS WARNING: To avoid errors in ordering the special instruments, refer exclusively to the inherent code. For correct maintenance and a perfect set-up use the BENELLI special instruments, avoiding damage as a result of inadequate or technically improvised instruments. MF13...

- Page 15 1.3.1 SPECIAL ENGINE INSTRUMENTS 1. R180197015000 GONIOMETER PLUG FOR DISTRIBUTION[*] 2. R180197017000 INSTRUMENT FOR MOUNTING CLUTCH OIL SEAL CASING [*] 3. R180197018000 CYLINDER MOUNTING SPACERS 4. R180197019000 SMALL CYLINDER COLUMN FIXING SPAN 5. R180197020000 FALSE SPARKING-PLUG 6. R180197021000 PISTON THREAD MEASURER MF13...

- Page 16 7. R180197022000 P.M.S. MEASURER 8. R180197023000 CLUTCH COVER OIL SEAL PAD [*] 9. R180197024000 OIL SEAL PINION PAD [*] 10. R180197025000 OIL SEAL VALVE PAD [*] 11. R180197026000 INSTRUMENT FOR CHECKING VALVE LIFT 12. R180197027000 GONIOMETER INDICATOR 13. R180197028000 CLUTCH OIL SEAL PAD ON FLANGE [*] MF13...

- Page 17 14. R180197029000 ENGINE SUPPORT 15. R180197030000 INSTRUUMENT FOR CHECKING ENGINE SHAFT AXIAL PLAY 16. R180197036000 ENGINE MANAGEMENT DIAGNOSTIC INSTRUMENT [*] 17. R180100143000 RAPID RELEASE PETROL TUBE KIT [*] 18. R180297130000 CLUTCH REGULATION KEY 19. R180297048000 DISMANTLING PINION INSTRUMENT MF13...

- Page 18 20. R180297047000 DISMANTLING CLUTCH INSTRUMENT 1.3.2 SPECIAL FRAME INSTRUMENTS 1. R180197033000 20 ALLEN WRENCH [*] 2. R180197031000 STEERING RING-NUT CLAMPS [*] 3. R180197034000 EMGINE DISMANTLING INSTRU- MENT[*] 4. R180197032000 ENGINE SHOULDER ADJUST- MENT CLAMPS [*] 5. R180297049000 COWLING SUPPORT TROLLEY MF13 (*) Compulsory instruments...

- Page 19 6. R180297129000 RING NUT REGULATION KEY AND STEERING LOCK NUT 7. R300097147000 CHAIN REGULATION TOOL 8. R300097146000 DISASSEMBLY TOOL STEERING PLATE MF13...

- Page 20 S S S S S pecifications SPECIFICATIONS 2.1 GENERAL SPECIFICATIONS 2100 1050 1443 Dimensions in mm Dimensioni in mm DIMENSIONS STANDARD LIMITS Engine length 2100 mm — Engine width 900 mm — Maximum height 1050 mm — Wheelbase 1443 mm —...

- Page 21 2.2 TECHNICAL CHARACTERISTICS: ENGINE ENGINE Type Three four-stroke cylinders in line Bore 88 mm Stroke 62 mm Total displacement 1130 cm Compression ratio 11,2:1 ± 0,5;1 Max. power at shaft [95/1/EC] 101 kw / 135 cv at 10500 rpm reduced for foreign countries 72 kw / 98 cv Minimum rotation at full speed 1350 rpm Maximum at full speed...

- Page 22 OILING/COOLING Oiling Humid housing with trochoidal circulation pump, opening pressure of the oil circuit valve, 6.5 bar. Engine oil quantity With filter: 4.0 l about Without filter: 3.8 l about Cooling Liquid, closed pressured circuit with radiator, thermostat and radiator oil air cooling. A centrifugal pump commanded by gears on the primary gearbox shaft circulates the liquid and an expansion tank recovers the thermal expansion of the cooling liquid.

- Page 23 2.3 FRAME CHARACTERISTICS FRAME STANDARD LIMITS Type Mixed steel-aluminium frame and structurre Angle of incidence 24,50° — Forward stroke 103,7 mm — FRONT WHEEL STANDARD LIMITS Type Cast — Dimensions: 17 x MT3.50 Material: aluminium Wheel span 120 mm — REAR WHEEL STANDARD LIMITS...

- Page 24 REAR TIRE STANDARD LIMITS Type Tubeless — Dimensions 190/55 ZR17 (73W) — Model D207 RR — Tire pressure cold 250 kPa (2,5 kg/cm, 2,5 bar) — Maximum tire pressure 250 kPa (2,5 kg/cm, 2,5 bar) — Min. depth tread — 2,0 mm FRONT BRAKES STANDARD...

- Page 25 FRONT SUSPENSION STANDARD LIMITS Type Telescopic fork with — upturned stems Type of front fork Helical spring/damper — Front fork stroke 120 mm — Spring Spring rate (K1): 9.5 N/mm — Spring stroke (K1): 0 ~ 120 mm — Oil advised SAE 7,5 Marzocchi 19 —...

- Page 26 OSCILLATING ARM STANDARD LIMITS Free play (at the end of the arm) Radial — 1 mm Axial — 1 mm TRANSMISSION CHAIN STANDARD LIMITS Model: REGINA 137-ORPB — Connection quantities — Play of the chain 30 ~ 40 mm — 2.4 ELECTRICAL CONNECTIONS COMPONENTS STANDARD...

- Page 27 COMPONENTS STANDARD Loading system Type: AC magnet Model: 5-101211-502-1 (DENSO) Nominal exit: 13.5V / 48A at 5000 rpm Tension adjustment (in the alternator) Type: Semiconductor, FIELD CONTROL Voltage adjustment: 14.5 ± 0.3V (at 5000 rpm, 10A and 25°C) Battery YUASA YTZ 14 S Electrical start system Model: 5-128-330 (DENSO)

- Page 28 BOLT TORQUE 2.5.1 GENERAL BOLT TORQUE The bolt torques are inserted in the chapters of the manual together with the relative special instructions, if necessary. If not otherwise specified, the bolts are considered with greased thread, created at environmental temperature. BOLT TORQUES kgf·m 4 mm...

- Page 29 2.5.2 BOLT TORQUE FRAME DESCRIPTION THREAD TORQUE (Nm) ENGINE GROUP: ENGINE ON BACK FUSION PLATE RIGHTHAND FRAME WITH LEFTHAND NUT ENGINE SUPPORT ROD ON ENGINE HEAD RIGHTHAND ENGINE ON LOWER CROSSBAR LOWER ENGINE CRANKPIN THROUGH FRAME WITH NUT LOWER CRANKPIN HEAD TORQUE ENGINE ON LOWER FRAME CROSSBAR (CLAMP) ENGINE HEAD ON RIGHTHAND FRAMEWORK WITH NUT RIGHTHAND ENGINE FIXING SCREW HEAD TORQUE ON...

- Page 30 SADDLE PILLAR GROUP: BACK FRAME HANDLEBAR GROUP COMMANDS: FRONT BRAKE PUMP HANDLEBAR CLUTCH LEVER HANDLEBAR PLATE FIXING PEDAL GROUP COMMANDS: PILOT FOOTBOARD ON FRAME SUPPORTS GEAR TORQUE COMMAND ON SHAFT DRIVING GEAR ROD ON GEAR COMMAND WITH NUT DRIVING GEAR ROD ON GEAR PEDAL WITH NUT PEDAL BEAT SPRING PIVOT UPPER BRAKE PEDAL SUPPORT LOWER BRAKE PEDAL SUPPORT...

- Page 31 REAR FORK GROUP: REAR FORK CRANKPIN SCREW ON REAR FORK CRANKPIN LOWER CHAIN GLIDING SHOE FORK UPPER CHAIN GLIDING SHOE FORK CENTRAL CHAIN GLIDING SHOE FORK FERRULES FOR ASSEMBLY STAND ON REAR FORK FRONT SUSPENSION GROUP: FERRULE STEMS ON STEERING BASE FERRULE STEMS ON STEERING HEAD FERRULE HUBS ON FRONT WHEEL CRANKPIN FRONT MUDGUARD SUPPORTS ON FORKS...

- Page 32 REAR WHEELGROUP: REAR WHEEL CRANKPIN NUT CROWN ON FLEXIBLE COUPLING FLANGE REAR BRAKE DISK ON WHEEL SPEED SENSOR ON CLIP SUPPORT LATERAL ASSEMBLY STAND GROUP: HANGER SUPPORT PLATE ON FRAME HANGER CRANKPIN ON FRAME SPRING HOOK ON HANGER ELECTRIC PLANT GROUP: IINERTIAL SWITCH ON FILTER BOX AIR SENSOR ON FILTER BOX COOLING PLANT GROUP:...

- Page 33 FRONT BRAKING PLANT GROUP: PUMP FRONT BRAKE ON HANDLEBAR FRONT BRAKE CLIPS ON RELATIVE SUPPORTS HYDRAULIC CONNECTIONS ON FRONT BRAKE PUMP AND CLIPS REAR BRAKING PLANT GROUP: REAR BRAKE PUMP ON RIGHT FOOTBOARD SUPPORT WITH NUT REAR BRAKE CLIP ON SUPPORT HYDRAULIC CONNECTION ON REAR BRAKE CLIP HYDROSTOP ON REAR BRAKE PUMP REAR BRAKE OILTANK ON EXPANSION VASE...

- Page 34 PETROL PUMP ON TANK PETROL TUBE ON THROTTLE BODY DISTRIBUTOR ON PLATE GAS CABLES FIXING PLATE ON THROTTLE BODY FRONT AND BACK BODYWORK GROUP: USE STANDARD TIGHTENING TORQUE WITH M6 THREAD FOR BODYWORK: 8Nm±20% MF13...

- Page 35 2.5.3 BOLT TORQUE ENGINE DESCRIPTION THREAD BOLT TORQUE (Nm) ENGINE CRANKCASE GROUP: CRANKCASE TEF FIXING SCREW CRANKCASE FIXING SCREW CRANKCASE BANKS TCEI FIXING SCREW OIL CONDUIT CLOSURE CONICAL DOWEL BALL-BEARING AND CRANKPIN FIXING SCREW SMALL PLATES AND TUBE FIXING SCREW CYLINDRICAL CAP CYLINDRICAL CAP OIL DIAPHRAGM...

- Page 36 PRISONNER SCREW HEAD BY STRIKING VENT HEAD CONNECTION DOWEL ENGINE GROUP/OILING: OIL PUMP FIXING SCREW OVERPRESSURE VALVE LARGE EXCHANGER FIXING SCREW OIL TUBE HEAD BORED SCREW OIL HEAD NIPPLE TUBE FILTER ENGINE GROUP/CRANK MECHANISM: PHONIC WHEEL FIXING NUT ROD SCREW 25+50°...

- Page 37 LOW CLUTCH ROD HEXAGONAL FIXING NUT CLUTCH SPRING FIXING SCREW CLUTCH HEXAGONAL FIXING NUT CLUTCH CONTROL FIXING SCREW ENGINE GROUP/GEARS: ENGINE PINION FIXING NUT ENGINE GROUP/ GEAR COMMAND: PLATE FIXING SCREW FORK PINS FIXING SCREW FORK PINS FIXING SCREW SELLET DRUM FIXING SCREW GEAR COMMAND SUMP FIXING SCREW GEAR COMMAND SUMP FIXING SCREW CHAIN COVER SUMP FIXING SCREW...

- Page 38 PHONIC WHEEL SENSOR SCREW ENGINE GROUP/ SUPPLY: THROTTLE BODY FIXING SCREW ENGINE GROUP: SUPPLY: FREE WHEEL RING FIXING SCREW ENGINE HEXAG. FLEXIBLE COUPLING SCREW ESAGONAL NUT ENGINE BUMPER TEF INGR. SATELLITE SCREW 2.6 POINTS TO OIL ENGINE OIL - Ball-bearings - Piston surface - Piston segments - Piston pin...

- Page 39 MF13...

- Page 40 MF13...

- Page 41 MF13...

- Page 42 MF13...

- Page 43 MF13...

- Page 44 MF13...

- Page 45 MF13...

- Page 46 MF13...

- Page 47 MF13...

- Page 48 MF13...

- Page 49 MF13...

- Page 50 MF13...

- Page 51 MF13...

- Page 52 P P P P P eriodical PERIODICAL CHECKS AND C C C C C ADJUSTMENTS hecks 3.1 INTRODUCTION This chapter includes information about checks and adjustments for better maintanence of the bike's performance. MAINTENANCE FREQUENCY 0 km 1000 km 6000 km 11000 km (0 mi) (625 mi)

- Page 53 MAINTENANCE FREQUENCY 0 km 1000 km 6000 km 11000 km (0 mi) (625 mi) (3750 mi) (6875 mi) COMPONENT OPERATION before delivery running-in Service Service Service Petrol filter Check/Change Throttle body Check/Change Air filter Check/Change Check/Change Pinion/Stop washer At every change of the transmission chain in any case Change Check/Adjust Transmission chain...

- Page 54 MAINTENANCE FREQUENCY 0 km 1000 km 6000 km 11000 km (0 mi) (625 mi) (3750 mi) (6875 mi) COMPONENT OPERATION before delivery running-in Service Service Service Transmissions and flexible Check/Adjust commands Steering crown saddle post Check/Adjust Steering saddlle post ball- Check/Adjust bearings Every 20000 km (12000 mi)

- Page 55 MAINTENANCE FREQUENCY 0 km 1000 km 6000 km 11000 km (0 mi) (625 mi) (3750 mi) (6875 mi) COMPONENT OPERATION before delivery running-in Service Service Service Locks Check/ Functioning Screws and nuts Check/Tighten Tube clamp straps Check/Tighten General oiling General test CODE: i = inspection and adjustment , cleaning, oiling or change according to need.

- Page 56 3.2 CHECK SPARKING-PLUGS WARNING: Changing and checking the sparking-plugs must be carried out with the engine cold. Remove the petrol tank (see “DISMANTLE TANK“). Remove the air box (see“DISMANTLE AIR BOX“). Remove the resonator. WARNING: Clean the dirt around the sparking-plugs before removing them.

- Page 57 3.2.1 INSTALLING SPARK-PLUGS Oil the sparking-plug threading, position it in its proper seat and tighten it. Install the candles on the cylinder head manually screwing them on until you reach the basis, then tighten to the indicated torque. 12 N·m 1,2 Kg-m NOTE: spark-plugs advised: CHAMPION RG4HC or NGK CR 9E 3.3 CLEAN AIR BOX...

- Page 58 NOTE: Check that the filtering element is always positioned with its side of major density turned upwards. ATTENTION: Before re-inserting the filtering element into the air box, eliminate excess oil by squeezing the element and checking that it is not dripping. Reposition the filtering element inside the air box Position the air box cover (2) and fix it with the nine screws.

- Page 59 Take off the Air Box base disconnect the air sensor connector below it. Remove the Air Box air duct (3). Check the state of the components visually, if necessary replace them. 3.3.2 SOLENOID MOTOR REMOVAL Remove the petrol tank. Loosen and remove the fixing screws (1). Loosen the nut (1) and the lock nut (2).

- Page 60 3.4 GAS COMMAND PLAY Check first at 1000 Km and then at every 5000 Km. The first adjustment is made during the installation of the gas command cables. Verify that the gas command handle works in a regular way and that reaching the position of maximum opening and that of automatic closing is possible in all the positions of the steering.

- Page 61 3.4.1 CLUTCH NOTE: Take the clutch cable off from the lower clutch command before setting the regulation of the clutch pack. Check every 5000 km. Position the bike onto the lateral stand to avoid oil spilling out when removing the clutch cover. Remove the clutch cover.

- Page 62 3.5 ADJUSTMENT CLUTCH LEVER PLAY Move the adjustment cover cap. Unscrew the crown (1) and restore the clutch lever play by turning the adjuster (2) clockwise or anti-clockwise. Clockwise the play diminishes. Anti-clockwise the play increases. The value of the clutch lever (A) must enter within the specific value.

- Page 63 Select on the display of the Axone the engineering parameters icon, then select fuel adjustment minimum, press enter. Connect a CO instrument tester to the exhaust plant. Take the engine temperature to 85°/90°C. The operation of adjusting the CO at minimum is recursive and must take into consideration contemporaneously variations in the Stepper position and the strength of the mixture.

- Page 64 3.7 ADJUSTMENT THROTTLE HOUSING Verify that the cables are assembled correctly and have the right clearance. Connect the minimum air ducts (1) of the throttle body to a vacuum gauge. Start the engine and warm it up to 85-90 degrees. Verify that the mercury columns (2) with the engine running at minimum are aligned, otherwise balance them.

- Page 65 Turn the engine off. Now connect the vacuum meter including also the stepper (2), leaving connected the bodies n° 2 and n° 3 to the vacuum gauge. Connect the connector (3) of the body n° 1 to the stepper. Proceed to reset the throttle by aid of the diagnostics tool. Start the engine and warm it up to 85-90 degrees.

- Page 66 Take off the clamps (2) disconnect the connection (3) pipes between stepper and throttle body. Take off the electric connector, remove the component. Check visually that the Stepper (4) does not present failures or deformation, otherwise replace it. Check visually that there are no obstructions inside the valve body (5) otherwise replace it.

- Page 67 3.9 ADJUSTMENT VALVE PLAY Remove the petrol tank (see "DISMANTLE TANK“). Rimuovere l’air box (vedi “SMONTAGGIO AIR BOX“). Remove the air box duct (see “AIR BOX DUCT DISASSEMBLY”). Remove the coils. (see “COIL DISASSEMBLY”). Remove the sparking-plugs. (see “SPARKING-PLUGS DISASSEMBLY”). Remove the head cover (see "DISMANTLE HEAD COVER").

- Page 68 3.9.1 VALVE TABLET REPLACEMENT Remove the chain stretcher. Remove the camshaft fixing bridges. Raise the cam shaft paying attention to keep all teeth of the distribution chain in place, allowing so the removal of the valve chap.s (1). Raise the valve chap.s (2) one at a time by aid of a magnet. Remove the valve tablet (3) replace it with a new one.

- Page 69 3.10 ENGINE DISTRIBUTION ATTENTION: Specific instruments are needed to set up the distribution: Indicator for goniomete • : R1801977027000 grip • Goniometer : R180197015000: DP-meter • : R180197020000 Valve lift verification equipment • : R180197026000 Remove the tank (see “tank disassembly”). Remove the air box (see “AIR box disassembly”).

- Page 70 At UDP set the comparators to (A) (B) (C) and the goniometer to zero. Rotate the goniometer hold clockwise the comparator (A) (aspiration) to 1 mm and check the goniometer value. SPECIFIC VALUE: Aspiration 21° opening ± 2° before the UDP 21°...

- Page 71 3.11 CHECK ENGINE OIL LEVEL WARNING: Do not mix chemical additives in the oil nor use types of oil different to that in the oils and liquids table. Make sure that foreign bodies do not penetrate into the casing during filling. ATTENTION: New or used engine oil can be dangerous.

- Page 72 WARNING: Danger: Do not start the engine if the oil is below the MIN. reference. Carry out the check cold with the engine off. If carried out while warm, the engine must be off for at least ten minutes. This check is carried out placing the mortorbike on a horizontal surface and in an upright position (vertical position).

- Page 73 ATTENTION: Used oils are harmful to the environment. Dispose of the used oils according to the regulations in vigour. Remove the oil loading cap (1). Remove the magnetic oil discharge chap. (2). Let all the used oil empty away. Loosen the screw (1) and remove the security clamp (2). Unscrew and remove the oilfilter (3).

- Page 74 To re-mount the oil filters (3), oil the surfaces of their contacts. NOTE: It is essential to use original Benelli filter oil Code: R180107101000. Oil filters of other brands can differ as far as the threading (diameter and step) is concerned.

- Page 75 3.13 CHECK COOLING LIQUID LEVEL WARNING: Filling the cooling liquid must always be carried out with the engine cold. Never try to remove the radia- tor cap when the engine is hot to avoid the risk of burns. ATTENTION: In determined conditions the ethylene glycol con- tained in the cooling liquid is inflammable and its flame is invisible.

- Page 76 To access the radiator CHAP., loosen and remove the screw (1) the upper closing lid (2) of the cooler right side. Remove the CHAP. and fill up to the upper limit of the radiators neck using recommended cooling liquid. Verify the reference MIN and MAX on the recovery tank. 3.14 CHANGE REFRIGERANT LIQUID NOTA:...

- Page 77 Remove the liquid discharge screw (2) on the pump (3) and recover the washer. NOTE: Let the cooling liquid empty away completely. NOTE: To facilitate the complete emptying of the cooling liquid contained in the cylinder blocks, lean the bike on both sides and press contemporaneously on the entry and exit rubber tubes of the radiator.

- Page 78 3.15 FILL COOLING PLANT NOTE: Carry out the following operations with the engine cold and the bike on the lateral assembly stand. Remove the radiator chap. lid (1). Remove the radiator chap. right side. Fill the circuit with about 3 litres of cooling liquid, through the supply pipe (2) up to the brim.

- Page 79 COOLING SYSTEM SCHEME HEAD FEEDING DUCT MF13...

- Page 80 3.16 CHECK FUEL TUBES Remove the tank (see "DISMANTLE TANK"). Take off the petrol pipe with the specific tool. SPECIFIC EQUIPMENT Petrol tube rapid release kit: R180100143000 Sight check the state of the fuel tube (1). If the tube is damaged or excessively worn, change it. Unscrew and remove the petrol pipe fixing screw from the injectors flute.

- Page 81 Loosen and remove the screw (3). Take off the holding spring (4), slip off the pipe union (B). Loosen the nut and the lock nut (5). Take off the valve recall cable (6). Slip off the three in one pipe union (c). MF13...

- Page 82 Unscrew and remove the screw’s nuts (7). Remove the manifolds (d). Check parts visually if particularly damaged or obstructed replace them removing the three in one pipe union (c). Verify if the choke valve is not obstructed, if required clean with solvent to remove the carbon deposits.

- Page 83 3.20 CHECK BRAKE LIQUID WARNING: An insufficient quantity of brake liquid may allow the penetration of air into the brake plant, reducing the efficiency of braking with a consequent increase in the risk of accidents. The presence of air in the hydraulic plant can be felt in the case in which, pressing the brake pedal, there is a sensation of excessive pliability.

- Page 84 3.21 CHECK FRONT AND REAR BRAKE PADS Unscrew and remove the fixing screws (1) of pliers. Take off and remove the elastic bulkhead (1). Extract the two elastic pivots (2), slip off the two fixing plugs (3) of brake blocks. Remove the brake blocks verifying that the thickness (A) is not under 3,5 mm.

- Page 85 Clean the inside of the pliers especially around the pistons. Push the pistons of the pliers simultaneously inside to allow the installation of the new brake blocks. Install the elastic bulkhead (1) with the arrow up (in march sense). Position the two blocks, insert the two plugs (2), insert the two elastic stoppers (3).

- Page 86 3.21.1 CHANGE REAR BRAKE PADS Remove the safety ring (4), undo the pin (5) on the opposite side and remove the spring (6). Replace the couple of blocks (7). Re-position spring (6), pin (5) and secure with ring (4). WARNING: After changing the brake pads, work on the brake command with long but not intense braking for about a hundred Km.

- Page 87 3.22 CHECK BRAKING PLANT TUBES Pull the break lever or the break pedal fully and check that no air did come into the system. If the lever or the pedal seem soft or elastic during use, discharge the air from the plant. Inspect the flexible pipes and the connectors of the brake to identify wear signs, cuts or losses.

- Page 88 In the case of the front brake before taking away the lid of the tank turn the handlebar until the tank is parallel to the ground. Unscrew and remove the screws (1), remove the lid. Remove the lid (2) membrane plate (3), the membrane and the float.

- Page 89 3.23.1 AIR DISCHARGE BACK BRAKE SYSTEM WARNING: To carry out the purge of the rear plant, the brake clamps of the relative support have to be dismantled and the plant tubing kept as vertical as possible. To discharge the back brake system proceed in the same way as at the front removing also the pliers from the support.

- Page 90 3.24 ADJUSTMENT GEAR COMMAND PEDAL Remove the fixing screws (3) of the gear pedal rod. Loosen the two nuts (1). Adjust the angle of the gear command pedal by working on the rod (2). Rotating it clockwise, the pedal will bend lower and vice versa if rotated anti-clockwise.

- Page 91 3.25 LUBRICATION AND CHAIN CLEANING LUBRICATE LUBRIFICARE WARNING: The chain is of the type with seal rings (O-Ring); to prevent any damages, do not clean the chain by jet of high-pressure steam or water, neither using petrol or commercial cleaning solvents. The chain cleaning must be done exclusively using kerosene.

- Page 92 Identify the knurled terminals (2) of the pivots of the main link from the outside of the chain, remove the main link, the plate and the O-ring. O-RING GOMMINI O-RING PIASTRA PLATE NOTE: When the links of the transmission chain are counted it is necessary to include the main link.

- Page 93 3.27 CHAIN REGULATION To make the following regulations position the motorcycle on a back trestle, on a horizontal plane with the gear in neutral. Loosen the eccentric blocking screws (1) on both sides of the fork. Insert the specific tool in the eccentric rotate clockwise to pull the chain and counter clockwise to loosen the chain.

- Page 94 WARNING: Use of the motorcycle with the chain in bad condition or never regulated can cause accidents. WARNING: If you note damages or excessive wear of the chain and the relative cog-wheels, replace them. Every time the chain is replaced also the relative cog- wheels must be replaced.

- Page 95 3.29 CHECK AND ADJUSTMENT STEER- ING BALL-BEARINGS Keeping the front brake drawn verify the clearance on the steering bearings. Check that the steering ball-bearings have no play. If necessary procede as follows. Unscrew and remove the handlebar plate fixing screws (1). Lower the handlebar on the tank.

- Page 96 Check the absence of play. If necesary, repeat the previous operations. Mount the handlebar. Mount the upper steering plate (1) (see "MOUNT FRONT FORK") Check the free rotation of the steering. 3.30 CHECK FORK Keeping the front brake drawn verify the state of the fork moving Sight check the state of the splashguards.

- Page 97 3.31 CHECK DAMPER Check the state of the rear damper as shown in the figure. If the rear damper needs maintenance, refer directly to the supplier listed in the "SPECIFICATIONS" chapter. 3.32 ADJUSTMENT DAMPER Two adjustments are possible on the rear damper: : - Preload spring adjustment (1) - Braking in extension adjustment (2) REAR SUSPENSION...

- Page 98 Adjustment of the preload spring is carried out using the two ring-nuts (1) and (2) in the figure. Loosen ring-nut (1) and adjust the preload with ring-nut (2). Clockwise, the preload will be more rigid. Anti-clockwise, the preload will be slacker. Once the preload is adjusted, tighten the ring-nut (1).

- Page 99 3.33 CHECK TIRE PRESSURE WARNING: Incorrect inflation of the tires causes serious danger in using the bike. Insufficient pressure can cause the the tire to slip on the rim or its detachment, with consequent deflation of the tire and loss of control of the vehicle.

- Page 100 3.34 CHECK WHEELS Check the radial and axial on the rear rim as in the figure. The value must enter within the specific value. SPECIFIC VALUE Axial veer = 0.3 mm Work on the front wheel as on the back wheel. SPECIFIC VALUE Axial veer = 0.05 mm Excessive veering and eccentricity are generally caused by wear...

- Page 101 3.35 CHECK AND OIL CLUTCH CABLE Check the free run of the cable in its sheath. If necessary, oil it with the advised oil. If the cable sheath is damaged, change both the cable and sheath together. WARNING: If the external body of the battery is damaged, sulphuric acid, a poisonous and extremely corrosive substance, may leak out.

- Page 102 Check the state of charge of the battery (1) with a tester (2) functioning as a voltmeter. If necessary recharge the battery. SPECIFIC VALUE Battery charge = 12.5V ATTENTION: These values vary according to the temperature, the condition of the battery plates and the level of the electrolyte.

- Page 103 ATTENTION: Pay attention never to remove the sealing fastenings of the MF battery. Recharge Environmental temperature Avoid the use of a nominal high potential battery charge because this forces the high amperage ten- sion too quickly inside the battery, causing the bat- tery to overheat with consequent damage to the plates.

- Page 104 RECHARGING WITH A VARIABLE TENSION BATTERY CHARGER Measuring the NOTE: Recharge wait over 30 minutes tension at empty Ampere meter before measuring the tension at before recharging. empty of the battery Connect the battery NOTE: Set the recharge tension to 16 ~ charger and an ampere 17V.

- Page 105 RECHARGING WITH A CONTINUOUS TENSION BATTERY CHARGER Measure the tension at NOTE: wait over 30 minutes empty before before measuring the tension at recharging. empty of the battery Connect the battery NOTE: Set the recharge tension to 16 ~ charger and an ampere 17V.

- Page 106 3.37 CHANGING FUSES The reload fuse (1) is on the left side of the engine in the posi- tion indicated. The spare fuse (2) is beside it. WARNING: Never use a fuse with a setting different to that speci- fied to avoid damaging the electrical plant of the motorcycle with a consequent danger of fire.

- Page 107 3.38 CHANGING FRONT LIGHTS To replace the front lights remove the right and left inspection chap.s of the parabolas unscrewing and removing the fixing screws (1). 3.38.1 FRONT LIGHT DISASSEMBLY Remove the front shield carrier (see “Front shield disassembly”). Unscrew and remove the screws (2) from the framelet. Take off the wiring connector front light (3).

- Page 108 Remove the lamp inspection lids. Unscrew the light fixing pivots (1). Unscrew and remove the central closing screw (2) from the framelet right and left. Loosen and remove the screws (2) remove the speed indicator, take off the connector (3) remove the light wiring. MF13...

- Page 109 3.39 ADUSTMENT FRONT HEADLIGHT To carry out the correct adjustment of the luminous beam pro- jected by the front headlight, position the vehicle at about 10 metres from a vertical wall on a perfectly flat terrain. Switch the front headlight on, sit on the vehicle in the driving position and check that the upper limit of the beam projected onto the vertical wall in less than about 1/10 with respect to the the horizontal axis of the lights.

- Page 110 3.40 BACK LIGHT DISASSEMBLY 3.40.1 CHANGING REAR HEADLIGHT This motorcycle is equipped with led lights. Loosen the screws (2) of the muffler and lower it to allow to remove the lamp. Cut the wiring blocking clamp (3), take off the connector (4). Loosen and remove the nuts (5), remove the light (6).

- Page 111 3.40.2 CHANGING LICENCE-PLATE LIGHT Loosen and remove the screw (1). Remove the rubber lamp-holder. Change the position lamp. Position the rubber lamp-holder and tighten the screw (1). 3.40.3 CHANGE FRONT AND REAR ARROWS 3.40.3.1 CHANGE FRONT ARROWS Cut the wiring fixing clamps. Loosen and remove screw (1).

- Page 112 3.40.3. BACK ARROW LAMP REPLACEMENT Loosen and remove the screw (1). Remove the arrow glass (2). Remove and replace the lamp (3). Reposition the glass (2) tighten the screw (1). MF13...

- Page 113 MF13...

- Page 114 C C C C C owling COWLING 4.1 TANK COVER DISASSEMBLY WARNING: Do not damage the cowling while removing. NOTE: Take note of the position of the screws for correct remounting. Unscrew and remove the screws (1) on the left cover, take off the cover pulling it towards away from the motorcycle.

- Page 115 4.2.1 COVER PLATE DISASSEMBLY Raise the adhesive. Unscrew and remove the screws (1). Extract the cover fixing plate (2). 4.2.2 PETROL PUMP REMOVAL Remove the petrol pipe (see “petrol pipe disassembly”). Disconnect the rapid unhooking petrol tube (8) from the pump using the specific equipment.

- Page 116 DISMANTLE TANK FUEL PUMP Remove the tank from the vehicle (see "DISMANTLE TANK"). Empty the tank, conserving the fuel in a dry place and far from the rays of the sun and open flames. Loosen and remove the six screws (1) and remove the pump (2).

- Page 117 4.4.1 FRONT SHIELD AND FRONT SHIELD SUPPORT DISASSEMBLY Unscrew and remove the screw (1). Take off the front shield support pulling it away from the motorcycle. Loosen and remove the screws (2) remove the front shield from the front shield support. COOLERS CONVEYORS DISASSEMBLY Position the motorcycle on the side stand.

- Page 118 Unscrew and remove the lower fixing screws (2) of the cooler. Take off the clamp (3) on the right cooler support from the inlet fixing. NOTE: Replace the clamp when reassembling. Take off the right cooler towards the outside from the supports allowing to slip from the ducts.

- Page 119 4.6 MUDGUARDS DISASSEMBLY 4.6.1 FRONT MUDGUARD DISASSEMBLY Take off the oil brake pipe blocking support from the mudguard (2). Unscrew and remove the screws (1). Slip off the mudguard. 4.6.2 BACK MUDGUARD DISASSEMBLY Unscrew and remove the screws (1). Slip off the mudguard (3). 4.7 CHAIN CARTER DISASSEMBLY Unscrew and remove the screws (4).

- Page 120 4.8 NUMBER PLATE HOLDER DISASSEMBLY Cut the wiring blocking clips (1). Take off the connectors of the back lights. Unscrew and remove the screws (2) on both sides of the exhaust. Remove the number plate holder MF13...

- Page 121 MF13...

- Page 122 ENGINE E E E E E engine MOTOR REMOVAL 5.0.1 MOTOR DISASSEMBLY FROM THE FRAME Take off the cooler covers. Remove the coolers. Dismantle Air box. Dismantle the fuel tank. Remove Air box duct. Remove cooler ducts. Disconnect the battery. Disconnect the remote control switch.

- Page 123 Loosen the screw (2) of the security arm band on the frame right side. Loosen the two screw s (3) and (4) fixing the motor upper right and left without removing them. Loosen the two security arm band screw s (5) of the lower motor fixing on the right side.

- Page 124 Loosen and remove the spindle (8) upper motor fixing. Place the motor ahead, and put a suitable support to the motor, remove definitively the two upper motor fixing screws, lower the motor and pull it out of the frame. 5.0.2 MOTOR ASSEMBLY ON THE FRAME Place the motor, lift and fix it with the two upper fixing screws.

- Page 125 Move the motor toward the frame back wall , connect the lower and upper motor fixing spindles without closing. Close the upper spindle (1) to the ledge, loosen again the ¼ revolution spindle, ritighten it to ledge. Close the ledge inside metal ring (2). MF13...

- Page 126 Close the ledge lower spindle (3). Close the two arm band security screws (4). Close the two upper fixing motor screws (5) and (6), close the arm band security screw (7). Install the small frame, close the couple of the upper fixing screws.

- Page 127 CAMSHAFT 5.1.1 REMOVE CAMSHAFT To remove the engine from the frame use the specific equipment. SPECIFIC EQUIPMENT Engine dismantling instrument: R180197034000 To support the engine use the specific equipment. SPECIFIC EQUIPMENT Engine support: R180197029000 Remove the access cover (1) to the phonic wheel. Position the phonic wheel as shown in the figure.

- Page 128 Remove the coils (4) and the sparking-plugs beneath. ATTENTION: Take note of the position of the screws for correct remounting. Unscrew the eight head cover fixing screws (5). NOTE: Replace the screws rubber tops (5) during reassembly. Remove the head cover. Remove the chain pad (6), unscrewing the two fixing screws (7).

- Page 129 5.1.2 CHECK CAMSHAFT Check the olives of the camshaft with a micrometer, as indicated in the figure. If the value does not enter within the specific measure, change the element. SUCTION SHAFT VALUE LIMIT: A= 36.6 mm B= 27.85 mm EXHAUST SHAFT: A= 36.6 mm B= 27.85 mm Check the deformation of the camshaft with a comparator, as...

- Page 130 5.1.3 CHECK CHAIN, SPROCKET WHEELS AND CAMSHAFT CHAIN GUIDE Check the state of wear of the camshaft distribution chain (1). If the element has blocked links, is excessively worn or has exceeded 40000 Km, change it. Sight check the distribution chain guides: 1 Fixed guide (FRONT PART) 2 Mobile guide (REAR PART) 3 Upper guide (FIXED ON HEAD)

- Page 131 5.1.4 CHECK CHAIN STRETCHER Check the free sliding of the chain stretcher rod. Check the state of the chain stretcher spring. Check the integrity of the chain stretcher. If an element or its components are damaged or ruined, change it/them. 5.1.5 MOUNT CAMSHAFT WARNING: To mount the camshafts correctly position the olives...

- Page 132 Position the transmission chain on the toothed wheels of the distribution shafts. Position the bridge and the upper chain pad and tighten the fixing screws in two phases as in the diagram in the figure. 1st phase: 6 N·m; 2nd phase: 13 N·m NOTE: Always oil the sliding parts with Teflon SINTOFLON paste.

- Page 133 Check that the posiiton of the cylinder 1 olives are turned to- wards each other as in the figure. Check that the position of the phonic wheel is as indicated in the figure (“A” and “B” aligned). Check the valve play with a feeler. If the valve play is not within the specific value, adjust the valve play (see "ADJUST VALVE PLAY").

- Page 134 ATTENTION: Always use new gaskets. Position the gaskets of the head cover (1 and 2 ). ATTENTION: Make sure during mounting that the gaskets (2) do not fall into the head. *Apply THREEBOND® paste as in the drawing. Position the cover of the head and insert the screws (3) and (4) where indicated in the figure.

- Page 135 Remove the two fixing joining elements (A) and (B) of the head and the lower crankcase and disconnect the oil tube (20). NOTE: Tighten the head cover fixing screws to the specific worm drive according to the order indjcated in the figure, paying attention not to cut or damage the gaskets.

- Page 136 5.2.2 CHECK CYLINDER HEAD WARNING: Do not use a pointed instrument to avoid damaging or scatching: Sparking-plug hole threading Valve seat Check and eventually eliminate carbon deposits in the combus- tion chamber with a rounded-off scraper. If the surface is damaged or scratched, change the element. Check the distortion of the cylinder head as indicated in the figure.

- Page 137 5.2.3 MOUNT CYLINDER HEAD NOTE: Always use new gaskets. Clean and degrease the head surface and the cylinders. Position the head/cylinder gasket. Position the cylinder head. Position the fixing washers and nuts. Tighten to the specified worm drive following the order in the figure in the following phases: 1st phase: 2.5 Kg-m;...

- Page 138 To remove the valves use a valve dismantling instrument (2) with the correct attachment (3), press the valve down and take off the two semi-cones. Loosen the clamp and remove the valve and its components as in the photo. The following procedure is applied to the valves (4), the springs (5 and 6) and relative components (7, 8 and 9).

- Page 139 5.3.2 CHECK VALVES AND VALVE GUIDES The following procedure must be carried out on all valves and relative valve guides. Check that values (A) and (B) are within the tollerance of the specific values. If values (A) and (B) are not within the value limits, change the elements.

- Page 140 Check the deformation of the legs of the valve. If the concentricity value does not enter within the margin, change the element. VALVE REFORMATION VALUE LIMIT 0.01 mm MF13...

- Page 141 5.3.3 CHECK VALVE SEATS The following procedure must be applied to all the valve seats. Eliminate eventual carbon deposits. Apply the tincture of bluing (b) on the face of the valve. Install the valve into the appropriate seat. Press it using the guide on the seat to leave an evident impression.

- Page 142 Apply disulfide of molybdenum to the stem of the valve. Insert the valve into the cylinder head. Rotate the valve until its face and seat shine uniformly, then remove the smoothing paste. NOTE: To obtain optimum smoothing results, strike the seat of the valve lightly while turning it forwards and backwards in your hands.

- Page 143 Bring the spring to a value length (c) and check the value of the load: VALUE LIMIT External spring length: 23.2 mm Load value limit: 565 N Internal spring length: 21.2 mm Load value limit: 314 N Check the inclination (a) of the valve spring as illustrated in the figure.

- Page 144 5.3.6 MOUNT VALVES The follwing procedure must be applied to all the valves and relative components. Oil the valve stem with the recommended oil. RECOMMENED OIL Disulfide of molybdenum oil Mount the lower small cup (1). Check that the thickness of the small cap is 1.5 mm. WARNING: Always use new gaskets and oil seals.

- Page 145 ATTENTION: The suction valves are larger than the exhaust valves. Insert the valves (4). Position the internal (5) and external (6) springs as shown in the figure. Insert the two lock cones (7) into the upper small cup (8). MF13...

- Page 146 Position the small cap as shown in the figure. Use the dismantling valve instrument making sure that the valve is correct. Position the calibrated pads (9) and the bucket-type tappets (10). ATTENTION Make sure that the individual valve lifters and the valve guide are re-mounted in the original position.

- Page 147 5.4.2 CHECK CYLINDER Check that the walls do not present signs of seizure with the pistons. Check the ovalisation of the cylinders as indicated in the figure. ATTENTION: In the case of changing the cylinder block also change the pistons and the elastic straps, if necessary. The cylinder is distinguished by a letter that indicates CLASS D1/D2...

- Page 148 5.4.4 CHECK WATER COLLECTOR Check eventual breaks on the collector and if necessary change the piece. 5.4.5 MOUNT WATER COLLECTOR ATTENTION: Always use new gaskets. Position the gasket (1)and the collector (2) and tighten the screws (3). 10 N·m 1 Kg-m 5.4.6 MOUNT CYLINDERS WARNING:...

- Page 149 PISTON 5.5.1 DISMANTLE PISTON Remove the cylinder (see "DISMANTLE CYLINDER BODY"). The following procedure must be applied to all 3 pistons. Remove the elastic ring (1). ATTENTION: Do not use hammers for the spindle removal (2). Remove pin (2) and remove piston (3). MF13...

- Page 150 5.5.2 CHECK PISTON The following procedure must also be applied to all the other pistons. 10,5 Check eventual breaks on the piston. Use a micrometer, as shown in the figure, to check that the value (P) enters within the specific value. CLASS ø...

- Page 151 5.5.4 SEGMENT-CABLE PLAY Measure the lateral play of the 1 and 2 segment using a feeler. If one of the two plays exceeds the limit specified, change both the piston and the segments. SEGMENT-CABLE PLAY SERVICE LIMIT:(1 ): 0.20 mm ): 0.18 mm SEGMENT CABLE WIDTH STANDARD: (1...

- Page 152 Check the value of (b). NOMINAL VALUE b = 19,002 ÷ 19,008 mm NOTE: If the play between the piston pin and the pin is more than 0.03 mm, change the piston. 5.5.6 MOUNTING SEGMENTS Install the segments in the order: scraper ring segment, 2nd segment, 1st segment.

- Page 153 Install the 2 segment (3) and the 1 segment (4). NOTE: The form and width of the 1st and 2nd segment are different. W4 = 3.1 ± 0.1 mm W3 = 3.7 ± 0.1 mm The 1 and 2 segment have the letter “N” on the upper side. Make sure that the marked side is turned upwards when being installed on the piston.

- Page 154 Position the piston (3), as shown in the figure, with the arrow on the piston pointing towards the exhaust. Insert the pin (4). ATTENTION: Always use new elastic rings for mounting the pistons. To avoid breaks that can take place with the rings bent. Position the two elastic rings (5), one for each side pay atten- tion not to deform them.

- Page 155 Remove the generator (2). Check the state of the flexible couplings of the tires. If they are worn or damaged, change them. 5.6.2 MOUNT GENERATOR To mount the generator, grease the O-ring and work in the re- verse way to dismantling, tightening screws (1) to the specific worm drive after having applied LOCTITE ®...

- Page 156 5.7.2 MOUNT PHASE SENSOR Position the sensor in its housing and fix with screw (2), and tighten. 10 N·m 1 Kg-m + LOCTITE 243 ® 5.7.3 REMOVE PHONIC WHEEL Remove the clutch cover (see "REMOVE CLUTCH COVER"). Unscrew and remove the screw and the washer (3) and remove the phonic wheel (4).

- Page 157 CLUTCH 5.8.1 DISMANTLE CLUTCH COMMAND Remove the clutch command cable and unscrew the three screws (1). Remove the clutch body command (2) and the cable support plate (3). Remove the ferrule (4) and the clutch command rod (5). 5.8.2 REMOVE CLUTCH COVER Place a container under the oil sump to allow the oil to empty.

- Page 158 5.8.3 REMOVE THE CLUTCH Remove the clutch cover, loosening the two centring screws (1) first, then the rest of the screws (2). Remove the six clutch disk pushing plate fixing screws (1). Extract the clutch plate (2). Extract the external teeth and internal teeth disk unit conductor MF13...

- Page 159 Remove the Belleville spring (4). Unscrew and remove the clutch fixing nut (5). Extract the sphere from inside the gear shaft with a magnetic tool (6). Remove the clearance adjustor (7) with the 4 mm thick projecting stop. Undo the drum (8). Undo the bell (9).

- Page 160 5.8.4 CHECKING THE EXTERNAL TEETH DISK CONDUCTOR The following operations must be carried out on all the external equipped disks. Check the external equipped disk liner. If it does not enter within the specific value, change the entire set of disks. VALUE LIMIT DISK LINER = 2.8 mm 5.8.5...

- Page 161 Bring the spring to a value length (c) and check the value of the load. The value C is the same for all springs. CLUTCH SPRING LENGTH c = 22 mm YELLOW SPRING LOAD VALUE LIMIT =170 N Check the incline (d) of the clutch spring as illustrated in the figure.

- Page 162 5.8.8 CHECKING PRIMARY CLUTCH BELL UNIT Verify that the primary assembly gear does not present an excessive wear, roughness or breaking. If necessary change the clutch bell unit and primary. 5.8.9 MOUNTING CLUTCH UNIT NOTE: There are two clearance elements for assembling the clutch unit.

- Page 163 Oil the ball-bearing slide area well. Insert the clutch bell unit (2) complete with roller bearings. Engage in sequence: Primary gear (4) Gear control alternator (5). MF13...

- Page 164 Oil pump gear (1) Insert the second (2) clearance element with the projection thickness (4.0 mm) towards the outside of the engine. Insert the clutch drum (3). Insert the slide plate (4) and relative 6 return springs (5) into the appropriate columns.

- Page 165 Insert the convex washer towards the outside of the engine. VERSO SIDE INSERIMENTO TO INSERT Insert the clutch bell unit fixing nut (1). Block the clutch bell unit with the specific instrument. Screw and tighten the nut with loctite. Worm drive: 80 N.M 8 Kgm Loctite: 648 ®...

- Page 166 Insert the Belleville spring with the convex side towards the inside of the engine (1). NOTE: The first steel internal teeth conduit disk is to be inserted with the friction band turned towards the inside of the engine. Insert in sequence alternating the conductor disks with external teeth (A) and conducted disks with internal teeth (B).

- Page 167 Reinsert the sphere (1). Insert the disk pushing plate (2), insert the springs and the screws alternated between them tighten to indicated torque. Worm drive 10N.M 1 Kg-m NOTE: Oil the screw threads. MF13...

- Page 168 5.8.10 ADJUSTING CLUTCH DISKS Block the flange (1), loosen the locknut (2) and screw up the adjuster (3) until it makes contact with the internal reaction rod, unscrew a ¼ turn. Check the play on the clutch control positioned on the opposite side of the engine.

- Page 169 5.8.11 MOUNT CLUTCH COVER NOTE: Before mounting the clutch cover, clean the contact surface with the engine (1) accurately without damaging it, change the clutch casing cover gasket. ATTENTION: Aways use new gaskets. Position the gasket and the clutch cover (1) and tighten with the centering screws (2) and then with screws (2).

- Page 170 5.8.12 MOUNT CLUTCH COMMAND Insert the clutch command rod (1). Insert the ferrule (2). Position the cable support rod (3) and the clutch command body (4). Fix the clutch command with the three screws (5) and tighten. Insert the clutch command cable. 10 N·m 1 Kg-m + LOCTITE 243 ®...

- Page 171 GEARS 5.9.1 REMOVE GEARS Remove the clutch unit. (see “REMOVING CLUTCH UNIT”). ATTENTION: Before removing the gears, remove the neutral sen- sor at the back of the engine. Loosen and remove the nine fixing screws (1) and remove the gears (2). 5.9.2 DISMANTLE GEARS Position the gears on a support.

- Page 172 WARNING: While removing pin (6), resist the reaction of the spring placed under the pawls (7). WARNING: Take note of the position of the forks before remov- ing them for correct re-mounting. Remove the sprocket wheel (6). Loosen and remove the two screws (8). Remove the stop plate (9).

- Page 173 ATTENTION: During the dismantling of the drum fixing pin, sup- port the positive valve gear (17) (see previous figure) to avoid it falling. Rotate the gear flange (external side above). Unscrew and remove the drum fixing pin (18), Remove the posiive valve gear (17) (see previous figure) and the gear selector drum (19).

- Page 174 5.9.3 CHECK GEAR FLANGE BALL-BEARINGS Check the free rotation of the ball-bearings (1) and (2). If necessary, change them. NOTE: It is necessary to remove plate (3), working on screws (4), to change the ball-bearings (1) and (2). 5.9.4 CHECK FORK GEAR AND SLIDE RODS The following procedure must be carried out on all the fork gears.

- Page 175 FORK GEAR SLOT WIDTH Measure the width of the fork gear slot using a cursor gauge. Fork slot length: Standard value: 5.0 – 5.1 mm FORK GEAR THICKNESS Measure the THICKNESS of the fork gear slot using a cursor gauge. Fork gear thickness: Standard: 4.8 –...

- Page 176 ATTENTION: Do not attempt to straighten the rod. Check the presence of curvature on a surface plate on the sliding rod. If necessary, change the element. 5.9.5 CHECK POSITIVE GEAR SHAFT VALVE Sight check the state of the guide on the positive shaft. If necessary, change it.

- Page 177 5.9.7 ASSEMBLE GEAR ATTENTION: Always use new gaskets and oil seals. Position the gear flange on a support (external side uppermost). Position the gear fixing spring (i) in the appropriate hole. Position the washer (2) and the gear fixing spring (3) and fix with the threaded pin (4).

- Page 178 Position the positive valve gear shaft as in the figure, supporting it with a suitable support. NOTE: Check, while mounting the gear selector drum, that the two elements shown coincide. Fix the drum (7) with the threaded pin (8) and tighten. NOTE: Once pin (8) is tightened it is possible to remove the support previously positioned under the positive val-...

- Page 179 Mount springs (10) and push rods (11) onto the flange (9). Position the pawls (12). Position the stop plate (13). Position the pre-mounted pin complete with sprocket wheel and pawl (15). MF13...

- Page 180 Fix the plate with the two screws (14) and tighten. Position the pre-mounted pin (15). 10 N·m 1 Kg-m + LOCTITE 243 ® Rotate the flange on the support (internal side above). Couple the primary and secondary shafts Position them as shown in the figure. Rotate the flange (external side above).

- Page 181 Position the O-Ring (16) on the secondary shaft. Position the spacer (17) with its minor dimension outwards. Position the pinion (18), the safety washer (19) and the nut (20). Tighten the nut. Bend the washer tongue. 140 N·m 14 Kg-m + LOCTITE 648 ®...

- Page 182 ATTENTION: Do not force the spring (21) too much while mount- ing the command shaft (22). Mount the spring (21) on the command shaft selector (22), as indicated in the figure. Insert the 3 mm thick spacer (22A) next to the spring. Insert the 1 mm thick clearance element (22B) on the selector shaft.

- Page 183 Position the command shaft selector (29), already pre-mounted, as shown in the figure. Insert on the shaft the smoother ( 29A ) of 0,8 mm thickness. Insert the oil seal (31) onto the gear command cover (30) with the appropriate instrument. Grease the internal lip, see chapter 2: specifications.

- Page 184 Insert the fixing screws (34) and tighten. 10 N·m 1 Kg-m 5.9.8 MOUNT GEARS ATTENTION: While mounting the gears make sure that they are in fourth gear to avoid breaking the neutral sensor. Otherwise, remove the neutral sensor before re- mounting the gears.

- Page 185 5.10 OIL SUMP AND OIL PUMP 5.10.1 DISMANTLE OIL SUMP Unscrew and remove the oil discharge cap (1) and the gasket beneath. Unscrew and remove the twelve screws (2) and remove the oil sump (3). 5.10.2 DISMANTLE OVERPRESSURE OIL VALVE Remove the oil sump (see "DISMANTLE OIL SUMP").

- Page 186 5.10.3 REMOVE OIL PUMP Remove the clutch unit. Remove the safety ring (1) and the toothed wheel (2) Unscrew and remove the three screws (3) and extract the oil pump (4). 5.10.4 DISMANTLE OIL PUMP Remove the oil pump shaft (1) complete with internal rotor (2). Remove the external rotor.

- Page 187 If necessary, remove the safety ring (4) and the internal rotor (5). Take off the pin (6). 5.10.5 CHECK OIL SUMP Check for breaks on the oil sump (1), eventually changing it. Check the presence of foreign bodies, eventually cleaning the drip filter.

- Page 188 The internal and external rotors should not be serrated. Check that the measurements (a) and (b) enter within the specific value, otherwise change the oil pump. 1: Internal rotor 2: External rotor 3: Pump body VALUE LIMIT a = 0.25 mm max. b = 0.2 mm max.

- Page 189 Insert the external rotor (6) as in the figure. Oil the two rotors abundantly. 5.10.8 MOUNT OIL PUMP Insert the oil pump from the right with the specific instrument until it touches, as in the figure. Insert the centering dowel. Fix with the three screws (7) and tighten.

- Page 190 5.10.9 MOUNT OVERPRESSURE VALVE Position the overpressure valve (1) and valve (2). Tighten. 25 N·m 2.5 Kg-m + LOCTITE 243 ® 5.10.10 MOUNT OIL SUMP ATTENTION: Always use new gaskets or O-rings. Position the two centering dowels on the base. Position the O-Ring (1) on the casing.

- Page 191 5.11 CASING 5.11.1 DISMANTLE CASING Remove the head. Remove the pistons (see “DISMANTLE PISTONS"). Remove the oil sump (see "DISMANTLE OIL SUMP"). Remove the oil pump (see "DISMANTLE OIL PUMP"). Remove the water pump (see "DISMANTLE WATER PUMP"). Remove the gears (see "ADJUSTMENT PHASE"). Remove the oil distributor ( see “OIL DISTRIBUTOR”...

- Page 192 Remove the five screws (6). Remove screw (7). Remove the two screws (8). MF13...

- Page 193 Remove screw (9). Remove the two screws (10). Loosen and remove screw (11). MF13...

- Page 194 ATTENTION: Take note of the position of the screws for correct re- mounting. Remove the nine screws (12) indicated in the figure (lower part of the engine). Remove the lower base (13). Remove the large plastic lock nut (14). MF13...

- Page 195 Remove the ring (15). Remove the balancing counter-shaft (16). Remove the engine shaft (17). ATTENTION: Take note of the position of the bronze bearings for correct re-mounting. Remove the four semi-bronze bearings (18). MF13...

- Page 196 Remove the drainage tube stop plate (19.) Remove the drainage tube (20). Remove the ball-bearings (21) and (22). Remove screw (23) and plate (24), freeing the pin (25). MF13...

- Page 197 Support the satellite gear (27) and take off the pin (26) as shown in the figure. Unscrew and remove the screw (28), the washer (29), the retaining plate and the female flexible coupling (30). Support the toothed wheel (31) and remove pin (32). Remove the toothed wheel (31).

- Page 198 Remove the spacer (33). Remove the free wheel (34). 5.11.2 DISMANTLE FREE WHEEL Remove the elastic safety ring. Remove the washer (1). MF13...

- Page 199 Remove the toothed wheel (2). Remove the roller cage (3). Remove the screws (4). MF13...

- Page 200 Dismantle the free wheel. 5.11.3 DISMANTLE BALANCING COUNTER SHAFT Remove the circlip (1). Remove the ball-bearing (2) and the toothed wheel (3). Remove the ball-bearing (4). MF13...

- Page 201 5.11.4 DISMANTLE ENGINE SHAFT ATTENTION: Take note of the position of the elements for correct re-mounting. The following procedure must be applied to all the connecting rods mounted on the engine shaft. Unscrew and remove screws (1). Remove the connecting rod (2) from the engine shaft (3). 5.11.5 CHECK CASING Check the presence of any breaks on the upper and lower cas- ing, eventually changing the casings, always coupled.

- Page 202 Check that the toothed wheels are not broken or excessively worn. Change them if necessary. 5.11.6 CHECK ENGINE SHAFT AND CONNECTING ROD Check eventual breaks or excessive wear on the whole engine shaft (1). Change the piece if necessary. Support the engine shaft with two “V” blocks and with the two ends resting upon the blocks, install a comparator and turn the engine shaft slowly.

- Page 203 Check eventual breaks or excessive play on the connecting rod (2) and on the two semi-bronze bearings. In case of replacement of the connecting rod, verify the belonging class marked on the shank (1). SELECTION SHEET TYPE COLOUR Ø CONNECTING ROD HEAD 40.395/40.401 Blue 40.401/40.407...

- Page 204 CONNECTING ROD HEAD WIDTH STANDARD: 2,18 - 2,19 mm CONNECTING ROD PIN WIDTH STANDARD: 22,0 - 22,05 mm 5.11.9 CHECK BALANCING COUNTER SHAFT Check the eventual presence of breaks on the balancing coun- ter shaft. Check the free rotation of the ball-bearings. Check eventual breaks or excessive wear on the toothed wheel.

- Page 205 5.11.10 CHECK FREE WHEEL Check eventual breaks, wear and slippage on the free wheel. Change the element if necessary. 5.11.11 ASSEMBLE FREE WHEEL Assemble the two elements as shown in the figure. Tighten screws (1). 17 N·m 1.7 Kg-m + LOCTITE 270 ®...

- Page 206 Position the roller-cage (2), oiling it. (See Chapter. 2: SPECIFI- CATIONS) Positon the toothed wheel (3). Position the washer (4) and fix with the circlip. MF13...

- Page 207 5.11.12 MOUNT ENGINE SHAFT CONNECTING ROD SEMI-BALL-BEARING WARNING: COLOUR SELECTION Various semi-bronze bearings liners exist distin- 1.680 - 1.684 guished by different colours (see table). Blue 1.684 - 1.688 Yellow 1.688 - 1.692 NOTE: Ø seat std A red 40.395 - 40.401 Position every bronze bearing of the right colour connected to its letter indicated on the connecting Ø...

- Page 208 Position the engine shaft on the upper semi-casing. Tighten the connecting rod screws in three phases. = 15 N·m 1,5 Kg-m = 25 N·m 2,5 Kg-m = + 50° NOTE: An angle torque control wrench is needed to carry out the third tightening phase. 5.11.13 MOUNTAGGIO BALANCING COUNTER SHAFT Position the ball-bearing (1) and fix with the circlip (2).

- Page 209 5.11.14 MOUNT CASING Position the roller cage (1), block it with washer (2) and fix with screw (3) tightly. 10 N·m 1 Kg-m + LOCTITE 243 ® Position the ball-bearing (4) with the apposite pad and fix with the circlip (5). Position the spacer (6) as indicated in the figure.

- Page 210 Position the free wheel (7) as shown in the figure. Position the toothed wheel (8) and insert pin (9) until touching, in the direction in the figure.. Position the flexible coupling, the washer retaining plate and tightened screw in the housing. Bend the retaining plate to avoid it protruding from the head of the screw.

- Page 211 Position the toothed wheel (13) as shown in the figure. Position pin (14) until touching, as indicated in the figure. Position plate (15) and fix with screw (16) tightly. 10 N·m 1 Kg-m + LOCTITE 243 ® MF13...

- Page 212 ATTENTION: Position the element highlighted in the figure. Position ball-bearings (17) and (18). ATTENTION: Position element (19) as shown in the figure. Insert the shower pipe (19) completely verifying the phase on the bearing sealing plate (A). Position the tube retaining plate and ball-bearing (20) and fix with screws (21) tightly.

- Page 213 Position and tighten the copper washer and the cap (22). 25 N·m 2,5 Kg-m ATTENTION: A type of semi-bronze bearing exists: Various liners of this semi-bronze bearing exist distinguished by different colours (see table). BENCH SEMI-BALL-BEARING COLOUR SELECTION 1.918 - 1.922 Blue 1.922 - 1.926 Yellow...

- Page 214 WARNING: Reading the letters must always be carried out starting from the side of the distribution chain. Position the four semi-bronze bearings (25) each slotted with the correct colour associated with its letter stamped on the outside of the casing (24), centering them with the tooth in the cable.

- Page 215 Make sure that the toothed wheels of the balancing counter shaft and the engine shaft are as shown in the figure. Position ring (28). Position the large cap (29), one per side, in the apposite seats. Put THREEBOND 1215 on the contact surfaces of the two casings.

- Page 216 Position the lower casing (30) on the upper. ATTENTION: Follow the mounting phases correctly. Position the eight screws (31) with washers and copper fat and tighten to torque in three phases according to the order printed on the carter. 13 N·m 1.3 Kg-m 25 N·m 2.5 Kg-m 45 N·m 4.5 Kg-m Tighten screws (32) in two phases.

- Page 217 Tighten screws (33) according to the order in the figure. 10 N·m 1 Kg-m Tighten screw (34). 10 N·m 1 Kg-m Tighten the two screws (35). With M8 screws, the worm drive is: 1° 13 N·m 1.3 Kg-m 2° 30 N·m 3 Kg-m MF13...

- Page 218 Tighten screw (36). With M8 screws, the worm drive is: 1° 13 N·m 1.3 Kg-m 2° 30 N·m 3 Kg-m Tighten the two screws (37) in two phases. With M8 screws, the worm drive is: 1° 10 N·m 1 Kg-m 2°...

- Page 219 Tighten the four screws (39). 1° 10 N·m 1 Kg-m Position balancing counter shaft ball-bearing stop plate (40) and fix with the two screws (41) tightly. 10 N·m 1 Kg-m ATTENTION: Always use new gaskets. Position the gasket and the counter shaft cover (42). Tighten the screws (43).

- Page 220 COOLING PLANT C C C C C P P P P P ooling lant REFRIGERANT LIQUID ENGINE Antifreeze density Freezing point The cooling circuit is filled in the factory with a 50:50 mixture of -30°C distilled water and ethylene glycol antifreeze. This 50:50 mixture provides optimum protection against both -40°C corrosion and temperature and shelters the cooling system...

- Page 221 RADIATOR 6.1.1 DISMANTLE RADIATOR Remove cooler fairings (see “COOLER FAIRING DISASSEMBLY”) Take off the elastic clamp (1) on the right side cooler pipe union. Take off the lower elastic clamp (2) on the cooler. MF13...

- Page 222 Remove the upper and lower fixing screws (1). Take off the cooler, disconnect the fan connector. Unscrew the screws (2). Remove the fan from the cooler (3). 6.1.1.1 LEFT COOLER DISASSEMBLY Remove the cooler fairings (see “fairing disassembly”). Take off the upper elastic clamp (1). MF13...

- Page 223 Take off the lower elastic clamp (2)on the cooler. Remove the upper and lower fixing screws (3). Take off the cooler. Disconnect the fan connector. MF13...

- Page 224 6.1.2 COOLER CHECK AND CLEANING Bent or indented tabs can be straightened with a small screwdriver. Dirt and foreign bodies must be removed. We recommend using compressed air for cleaning. Repair or change the radiator if necessary. If any water-carrying tube is cracked or flattened, it must be removed.

- Page 225 6.1.4 OIL RADIATOR DISASSEMBLY Put the container under the oil filter to impound the oil to blow off. Remove the two pipes fittings (A) and (B) on the oil distributor. Blow off the oil in the container. Loosen and remove the two pipe unions (A) and (B) on the oil cooler.

- Page 226 Loosen and remove the cooler fixing screws (1). Take off the cooler from the support removing it. 6.1.5 OIL COOLER CHECK AND CLEANING Verify the radiator wings conditions. Bent or nicked wings can be rectified with a small screwdriver. For the cleaning the foreign materials must be removed. For the cleaning we suggest you to use compressed air.

- Page 227 Close in couple the two connectors (5/6) on the radiator. 30 Nm 3 Kg-m Put the two oil delivery and recovery tubes (A) and (B) on the distributor. Close in couple the two connectors (5/6) on the distributor. 30 Nm 3 Kg-m WARNING: Fit the oil with about 400cc, make the starting motor rotate without switching on the motor, favouring in...

- Page 228 6.2 OIL DISTRIBUTOR Remove the exhaust system. Remove the engine oil filter (1) ( see “ OIL FILTER REMOVAL“). Disconnect the inlet and outlet pipes of the oil distributor. NOTE: Take care not to lose the clearance. Loosen and remove the screw (2) and remove the distributor. Loosen and remove the two underlying screws.

- Page 229 6.2.1 OIL DISTRIBUTOR ASSEMBLY Oil the O-Ring (1) on the distributor. Place the oil distributor with the phase plaque without closing the two screws (A). Close in couple, in two phases the connector screw (2). 1° phase: 30 N·m 3 Kg-m 2°...

- Page 230 THERMOSTAT 6.3.1 DISMANTLE THERMOSTAT WARNING: Always use new gaskets and oil seals. Remove the refrigerant liquid from the cooling circuit (see "CHANGE REFRIGENRANT LIQUID"). Remove the tube (1) loosening the clamp (2). Loosen and remove the two screws (3) and remove the thermo- stat cover (4).

- Page 231 6.3.2 CHECK THERMOSTAT The thermostat begins and opens at around 75°C and reaches 7 mm minimum opening at 90°C, as shown in the diagram in the figure. TEMPERATURE Check whether the thermostat pad is cracked. SPAGO CORD Pass a cord through the flange as indicated in the figure. Check the above-mentioned conditions by immerging the thermostat (1) in a container with water, maintaining it in suspension.