- KY CDL Pretrip Videos

FREE 2024 Kentucky (KY) Pretrip

2024 ky pretrip.

Based on the 2024 KY CDL Driver's Manual

More kentucky cdl practice test: ( indicates current test), general knowledge 1, general knowledge 2, general knowledge 3, general knowledge 4, general knowledge 5, general knowledge 6, general knowledge 7, general knowledge 8, school bus 1, school bus 2, school bus 3, school bus 4, passenger vehicles 1, passenger vehicles 2, passenger vehicles 3, passenger vehicles 4, air brakes 1, air brakes 2, air brakes 3, air brakes 4, combination vehicles 1, combination vehicles 2, combination vehicles 3, combination vehicles 4, combination vehicles 5, double/triple trailers 1, double/triple trailers 2, double/triple trailers 3, tanker vehicles 1, tanker vehicles 2, tanker vehicles 3, pre-trip inspection 1, pre-trip inspection 2, pre-trip inspection 3, kentucky free pretrip videos, engine compartment pretrip inspection, inside cab pretrip inspection, rear of tractor pretrip inspection, exterior light pretrip inspection, complete trailer pretrip inspection.

Serving your CDL Learner Permit requirement needs

- Kentucky CDL Permit Training Program

- | 2024 KY CDL Skills Tests

- KY CDL Pre-Trip Inspection

Kentucky CDL Pre-Trip Checklist Vehicle Inspection (Walk-Around) Skills Test

First of three kentucky cdl skills tests - the kentucky cdl vehicle checklist inspection skills test must be passed prior to being allowed to continue., there are three parts to the kentucky cdl skills test.

- First Part: Kentucky CDL PreTrip Inspection on THIS page . . .

- Second Part: Kentucky CDL Basic Vehicle Control

- Third Part: Kentucky CDL Road Test

Kentucky CDL Pre Trip Inspection Diagram

Vehicle Pre-Trip Checklist Inspection - Kentucky CDL Skills Tests:

Quick study guide to kentucky cdl pre-trip inspection.

- Engine Compartment

- Cab Check and Engine Start

- Brake Check

- External Cab

1. Kentucky CDL Engine Compartment Pre-Trip Inspection

- Look for puddles on the ground that would indicate a leak.

- Look for dripping fluids on the underside of the engine and transmission.

- Inspect hoses for "good" condition and leaks.

- Indicate the location of dipstick.

- Make sure the oil level is within safe operating range and above the refill mark.

- a) Checking the reservoir sight glass, or

- b) Removing the radiator cap if the engine is not hot and visually checking the coolant level.

- Indicate the location of the power steering fluid dipstick.

- Confirm that there is an adequate power steering fluid level that is above the refill mark.

- power steering belt

- water pump belt

- alternator belt

- air compressor belt

2. Kentucky CDL Cab Check and Engine Start - Pre-Trip Inspection

- Manual Transmissions:

- Depress the clutch.

- Place the gearshift lever in neutral.

- Start the engine and then slowly release the clutch.

- Automatic Transmissions:

- Confirm the vehicle is in �park� and start the engine.

- Confirm that the oil pressure gauge is functioning.

- Make sure that the pressure gauge shows increasing or normal oil pressure, otherwise that the warning light goes off.

- If equipped with an oil temperature gauge, it should begin to gradually rise to a normal operating range.

- Confirm that the temperature gauge is working.

- The temperature gauge should begin to climb to the normal operating range.

- The gauges should show the alternator and/or generator charging; otherwise the warning light should be set off.

- Check for proper operation and acceptable readings on the air and vacuum gauges.

- The speedometer should not be obscured or obviously broken.

- Mirrors should be clean and adjusted properly from the inside.

- Windshield should be clean with no illegal stickers, obstructions, or damage to the glass.

- Three red reflective triangles.

- One properly charged and rated fire extinguisher.

- Spare electrical fuses.

- Power steering equipped vehicles: With the engine running, play should not exceed 10 degrees (or about two inches on a 20-inch wheel) before the front left wheel barely moves when you turn the steering wheel back and forth.

- Non-power steering vehicles: Play should not exceed 10 degrees (or about two inches on a 20-inch wheel) when you turn the steering wheel back and forth.

- Check that the wiper arms and blades are not damaged and operate smoothly.

- Windshield washers must operate correctly if the vehicle is equipped.

- Left turn signal

- Right turn signal

- 4-way emergency flashers

- High beam headlight

- Check that air horn and/or electric horn are operational.

- Test that the heater and defroster works.

- Check that the safety belt is securely mounted, adjusts, and latches properly.

- Clearance lights (red on rear, amber elsewhere)

- Headlights (high and low beams)

- Turn signals

- 4-way flashers

- Brake lights

- Red reflectors (on rear) and amber reflectors (elsewhere)

3. Kentucky CDL Brake Check Pre-Trip Inspection

- Apply parking brake only and shift into a lower gear. Gently pull against the brake by releasing the clutch, and it should hold the vehicle.

- With the engine running, apply the foot brake and hold for five seconds. The pedal should not move (lose pressure) during those five seconds.

- If equipped with a hydraulic brake reserve system, with the key in the off position, depress the brake pedal and listen for the sound of the reserve system electric motor turning on.

- Check that the warning buzzer and light is off.

- Check the proper operation of the foot brake by moving the vehicle forward slowly at about 5 mph and applying the brake firmly.

- With a fully-charged air system, typically at 120 psi, turn the engine off, chock the wheels, release (push in) the parking brake button and trailer air supply button (for combination vehicles) and time the air pressure drop. After the initial drop, the rate of pressure loss should not be more than 2 psi per minute for single vehicles and no more than 3 psi per minute for combination vehicles

- Release (push in) the parking brake and trailer air supply button (for combination vehicles), and apply pressure to the foot brake. After the initial drop in pressure, the rate of pressure loss should be no more than 3 psi per minute for single vehicles and no more than 4 psi per minute for combination vehicles.

- Turn the key to the on position. Rapidly depress and release the foot brake to reduce air tank pressure. The low air pressure warning signal must come on before the pressure drops below 60 psi.

- Continue to rapidly apply and release the service brake pedal further reducing air pressure. The trailer air supply button (for combination vehicles) and parking brake button should pop out when the pressure falls to usually between 20 to 40 psi. This should activate the spring brakes.

- While the engine is operating at 1800 RPM, the pressure should rise from 85 to 100 psi within 45 seconds in dual air systems.

- With normal air pressure, release the parking brake and trailer air supply button (for combination vehicles), move the vehicle forward slowly at about 5 mph and apply the brakes firmly using the brake pedal. Test for any pulling to any one side or delayed stopping action.

4. Kentucky CDL External Cab | Truck | Bus Pre-Trip Inspection

- Check that the steering box is mounted securely and is not leaking.

- Check for damage to power steering hoses and power steering fluid leaks.

- Check that connecting links, arms, and rods from the steering box to the wheels are not worn and cracked.

- Check that the joints and sockets are not loose or worn and that there are no missing nuts, bolts, or cotter keys.

- Check for shifted, cracked, broken, or even missing leaf springs.

- Check for broken and distorted coil springs.

- If equipped, check the air ride suspension for damage and leaks.

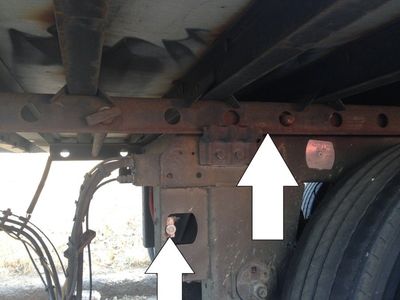

- Look for cracked or broken spring hangers, missing or damaged bushings, and broken, loose, or missing bolts, U-bolts or other axle mounting parts.

- Confirm that the shock absorbers are secure and that there are no leaks.

- Look for missing, loose or broken parts.

- The angle between the adjuster arm and push rod should be not less than 90 degrees when the brakes are applied and when the brakes are released a little over 90 degrees.

- When pulled by hand, the brake rod should not move more than one inch with the brakes released.

- Check that brake chambers are not dented, cracked, or leaking and that they are mounted securely.

- Check for worn, cracked or leaking hoses, lines, and couplings.

- Check for dents, cracks or holes, and loose or missing bolts.

- Brake linings and pads should not be worn thin.

- Where visible, check that a reasonable amount of brake lining is showing.

- Check for damaged or bent rims. Rims cannot have welding repairs.

- Tread depth: need a minimum tread depth of 4/32 on steering axle tires, 2/32 on all other tires.

- Tire condition: Check that tread is evenly worn and without cuts or damage to tread or sidewalls. Valve caps and stems should not be missing, broken, or damaged.

- Tire inflation: Check for proper inflation with a tire gauge or by striking tires with a mallet.

- Check that hub oil/grease seals and axle seals are not leaking.

- Check for any missing lug nuts, cracks, distortions, and for signs of looseness such as rust trails or shiny threads.

- Check for cracked or distorted bolt holes.

- Spacers should not be bent, damaged, or rusted through.

- Spacers should be centered evenly.

- Check doors for any damage and that they open and close properly.

- Hinges should be secure with seals intact.

- Mirrors and mirror brackets should be mounted securely.

- Check for secure tanks, tight caps, and that the tanks or lines don�t leak.

- Check to see that batteries are secure, for tight cable connections, and that cell caps are present.

- Check for signs of excessive corrosion.

- Battery box and cover/door must be secure.

- The drive shaft should not be bent or cracked.

- Couplings should be secure.

- Check system for rust or carbon soot as they are signs of damage or leaks.

- System should be secure and connected tightly.

- Check the longitudinal frame members, cross members, box, and floor for cracks, broken welds, holes or other damage.

- If equipped with mud flaps or splash guards, check that they are mounted securely and not damaged.

- Doors and hinges must open, close, and latch properly from the outside, and should not be damaged.

- Check that any ties, straps, chains, and binders are secure.

- If equipped with a cargo lift, it must be fully retracted and latched securely, and should not be leaking, damaged or missing any parts.

- Check that electrical lines and air hoses are not cut, chafed, spliced, or worn, the steel braid should not show through its outer lining.

- Make sure the lines and hoses are not tangled or dragging against tractor parts.

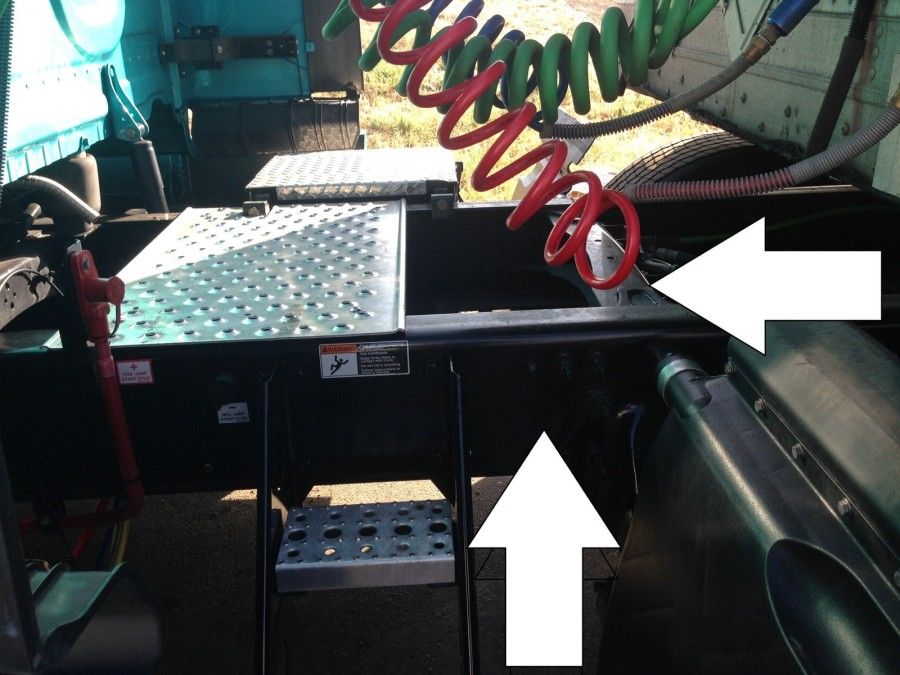

- Make sure the catwalk is securely bolted to tractor frame.

- Check for loose or missing mounting brackets, clamps, bolts, or nuts. The fifth wheel and the slide mounting must be solidly attached.

- Other types of coupling systems should be inspected for missing or broken components.

- Check that the locking jaws fully close around the kingpin

- On other types of coupling systems the locking mechanism should not have missing or broken parts and should lock securely.

- The platform structure supporting the fifth wheel skid plate should be free of cracks or breaks.

- If equipped with a release arm, check that it engaged and that the safety latch is in place.

- The kingpin should not be bent.

- The visible part of the apron should not be bent, cracked, or broken.

- The trailer should be laying flat on the fifth wheel skid plate without any gap.

- Locking pins should be fully engaged.

- The fifth wheel should be positioned so the tractor frame will not strike the landing gear or the tractor.

5. Kentucky CDL Trailer Pre-Trip Inspection

- The trailer air connectors should be sealed and in good condition.

- Glad hands should be locked in place and free of damage or air leaks.

- The trailer electrical plug should be firmly seated and locked in place.

- If equipped with a header board, check to see that it is secure, damage-free and strong enough to contain cargo.

- If equipped with a canvas or tarp carrier, it should be mounted and fastened securely.

- Check the front area of enclosed trailers for cracks, bulges or holes.

- The landing gear must be fully raised. Check that it has no missing parts with a non-damaged support frame and that the crank handle is secure.

- Check for air or hydraulic leaks if power operated.

- Check that doors are not damaged and that they open, close, and latch properly from the outside.

- Ties, straps, chains, and binders should be secure.

- Any cargo lifts should be checked for leaking, damaged or missing parts, and should be fully retracted and latched securely.

- The frame, cross members, box, and floor should be checked for holes, cracks, broken welds or other damage.

- If equipped, make sure that the release arm is secured and that the locking pins are locked in place.

- Suspension System

- Doors, Ties and Lift

- Splash Guards

Are YOU ready to get YOUR Kentucky CDL? Prepare for YOUR Kentucky CDL Tests NOW . . .

- In separate study modules - you won't need all of them - don't waste time on what you don't require.

- 670 practice Kentucky CDL test questions with actual answers.

- Access to CDL videos covering written and skills tests.

- CDL study guide in both text and audio - listen as you read along .

- CDL study Quick Reviews.

- Interactive online CDL Quizzes.

- and much more!

Pretrip Inspection Test

Cdl pretrip inspection test made easy: video tutorial, mastering the cdl pretrip inspection test: a step-by-step video guide introduction.

Are you preparing for the CDL pretrip inspection test and feeling overwhelmed? Don't worry; we've got you covered! In this comprehensive guide, we will walk you through the essential steps of the pretrip inspection test, focusing on the value of instructional videos for mastering the process.

Importance of CDL Pretrip Inspection

Before we delve into the instructional video, let's understand why the CDL pretrip inspection is crucial. It's a vital part of the CDL test, ensuring that drivers can identify and address any issues with their commercial vehicles before hitting the road.

The Challenge of Pretrip Inspection Test

For many aspiring commercial drivers, the pretrip inspection test can be perplexing. It requires a burst of attention to detail, as missing even a single step can lead to failure. However, breaking down the process into manageable steps can make it less overwhelming.

Navigating the Complexity with Video Instruction

One of the most effective ways to master the pretrip inspection test is by watching instructional videos. These videos provide a visual guide, allowing you to see each step in action and understand the intricacies of the inspection process.

Clear Visual Demonstration

Video instruction offers a clear demonstration of each component of the pretrip inspection. From checking the tires and brakes to examining the lights and indicators, seeing the process in action can significantly enhance your understanding.

Accessible Learning Resources

Instructional videos are readily available online, providing aspiring commercial drivers with easy access to valuable learning resources. With just a few clicks, you can access a wealth of video tutorials that break down the pretrip inspection into digestible segments.

Engaging and Informative Content

By utilizing instructional videos, you can engage with the content in a more interactive manner. The active voice used in the videos prompts you to participate mentally, enhancing your retention of essential information.

The Power of Detailed Guidance

In the context of the CDL pretrip inspection, detailed guidance is paramount to success. An instructional video that offers specific and clear instructions can significantly boost your confidence and competence in performing the inspection.

Step-by-Step Narration

An ideal instructional video provides step-by-step narration, guiding you through each part of the pretrip inspection process. This detailed approach ensures that no aspect is overlooked, building your proficiency in conducting a thorough inspection.

Visual Analogies for Understanding

Incorporating analogies and metaphors in instructional videos can make complex concepts easier to grasp. For instance, comparing the inspection process to a routine health checkup can help drivers relate to the significance of each inspection component.

Emphasizing Safety and Compliance

A well-crafted instructional video will emphasize the importance of safety and regulatory compliance throughout the pretrip inspection. This ensures that drivers understand the underlying purpose of each inspection element, fostering a safety-oriented mindset.

Mastering the CDL pretrip inspection test is achievable with the right guidance and resources. Leveraging instructional videos as a part of your preparation can provide you with a clear advantage in understanding the intricacies of the inspection process. With accessible, engaging, and detailed video guidance, you can approach the pretrip inspection test with confidence and competence.

Full pre-trip inspection on your Class A truck for the new CDL road test

This video will explain the full pre-trip inspection on your Class A truck for the new CDL road test. Watch the whole thing to learn the new pre-trip.

CDL Driving Academy is the GREATEST CDL school available in the United States. We offer training for your CDL permit, simulation training with our state-of-the-art trucking simulator, AND hands-on yard and road training to prepare you for your CDL road test. If you are looking to get a CDL and want to train with only the BEST CDL school, give us a call TODAY to get started on your ROAD TO FREEDOM with your new career!

For the CDL Class A Road test, the CDL Class A Pre-Trip Inspection is the hardest part. The reason most people fail their CDL CLass A Road Test is because they do not get the right CDL Class A training and that makes them fail the Pre-trip inspection. The Road Test is split into 3 different sections the first part of the CDL Class A road test is to pass the CDL Pre-trip inspection you are going to be asked to do both an Inside air brake test as well as an Outside pre-trip inspection. The second part of the CDL Class A road test is a skills test. The student will have to master six different parking maneuvers and the last part of the CDL Class A road test is the road driving. This test will take two and a half hours to complete however it all starts with this CDL pre-trip inspection.

Most people fail in the first 10 mins of the test because they did not get the proper CDL Class A training on the pre-trip inspection. That is why we have created this video to show you how our students at Driving Academy get the proper CDL Class A training they need in order to pass the CDL Class A Road Test. We offer this video and much much more to our students when we train them for their CDL Class A Pre-trip Inspection. Our students get our highly trained instructors to help them with the CDL Class A pre- trip inspection, they also get a word for word script on exactly what to say during their CDL Class A Road test, and they also get to practice on the same CDL Class A truck that they will be taking their test in as well. After our CDL training program our students are ready to take this test and become successful CDL Drivers and start making Big Money. After our students pass the CDL Class A Pre-trip Inspection they get help with our free life time job placement program. This is where it is our Job to help Students find their CDL Class A Job. Once they Get their CDL Class A Job they will have to do the CDL Class A Pre Trip Inspection if they have followed our training and plan to be the best CDL Class A Driver they can be. They will Learn that when they do their CDL Pre-Trip inspection on a daily basis they will be able to catch things when they are small and fix them so it does not cost them too much money or time at their CDL Class A Job.

CDL DRIVING TEST/ CDL ROAD TEST/ CLASS A PRE-TRIP INSPECTION CDL ROAD TEST/ CDL PRE TRIP/ PRE TRIP INSPECTION CLASS A/ PRE TRIP INSPECTION TEST / CDL PRE TRIP INSPECTION CLASS A / CDL INSPECTION

You may also like

FREE Kentucky CDL Pre-Trip Inspection Practice Test 2024 | KY

Do you think that you can pass the CDL pre-trip exam on the first try? Want to increase your chances of walking away from the DMV without having to re-register for the test? Try our Free Kentucky CDL Pre-Trip Inspection Practice Test to improve your knowledge and see what types of questions will be asked on the real exam. We ask 30 questions about inspecting your rig, trailer, and cargo to ensure you firmly grasp the concepts. We used the official Kentucky CDL Handbook to ensure that our information is relevant to you and your exam! If you can score an 80% or above, you will pass the test and have a powerful study tool in your possession.

Re-taking the pre-trip inspection exam costs both time and money. If you are serious about passing the exam on the first try, take our Free Kentucky CDL Pre-Inspection Practice Test today!

Kentucky CDL Pre-Trip Inspection Overview:

Get the latest (2024) official KY CDL Manual.

Select Another KY CDL Practice Test

- General Knowledge Test 1

- General Knowledge Test 2

- General Knowledge Test 3

- KY CDL Air Brakes Test 1

- KY Combination Vehicles Test 1

- KY CDL HazMat Test 1

- KY CDL Tanker Vehicles Test 1

- KY Double/Triple Trailers Test 1

- KY Passenger Vehicles Test 1

- KY CDL School Bus Test 1

- KY CDL Pre Trip Inspection Test 1 (you are here)

- General Knowledge Test Simulator

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

Catwalk and Steps

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

CDL VEHICLE INSPECTION TEST KENTUCKY

Ky cdl inspection test.

PRE-TRIP VIDEO

- Free Practice Tests

Commercial Driving

- Introduction

Getting a CDL

- Fees and costs

CDL Types & Permits

Endorsements & Restrictions

CDL Exam Preparation

Written exams

Practical exams

- Skills test

- Pre-trip inspection

- TSA background check

- Retake policy

CDL Maintenance

ELDT Training & Certification

CDL how-to guides

COMMENTS

Passing the 2024 Kentucky KSP CDL exams made easy. With over 30 years experience in the CDL field we have more questions that appear on the CDL written exams than any other site. ... and explain 2-3 things that you would check each item for. The content from these videos are based on the Kentucky Commercial Driver License Handbook. Based on the ...

3. Kentucky CDL Brake Check Pre-Trip Inspection. Parking Brake Check. Apply parking brake only and shift into a lower gear. Gently pull against the brake by releasing the clutch, and it should hold the vehicle. Hydraulic Brake Check. With the engine running, apply the foot brake and hold for five seconds.

Prepare for your CDL Examination by learning from this video. This is a complete demonstration of performing pre-trip inspection of the entire tractor/traile...

This video will explain the full pre-trip inspection on your Class A truck for the new CDL road test. Watch the whole thing to learn the new pre-trip.Our Web...

In this Video, you'll learn The full pre-trip inspection procedure the proper way. Get CDL Training for Free on Youtube. Getting the CDL is not just passing ...

This CDL practice test is a great place to start if you're after the KY Pre-Trip Inspection endorsement. Each of the 20 questions is based on the official 2024 CDL manual. The test is designed to prepare you for the Pre-Trip Inspection portion of your 2024 Commercial Driver's License exam. There are several answer options, but only one of ...

Importance of CDL Pretrip Inspection. Before we delve into the instructional video, let's understand why the CDL pretrip inspection is crucial. It's a vital part of the CDL test, ensuring that drivers can identify and address any issues with their commercial vehicles before hitting the road. The Challenge of Pretrip Inspection Test

The Road Test is split into 3 different sections the first part of the CDL Class A road test is to pass the CDL Pre-trip inspection you are going to be asked to do both an Inside air brake test as well as an Outside pre-trip inspection. The second part of the CDL Class A road test is a skills test. The student will have to master six different ...

Try our Free Kentucky CDL Pre-Trip Inspection Practice Test to improve your knowledge and see what types of questions will be asked on the real exam. We ask 30 questions about inspecting your rig, trailer, and cargo to ensure you firmly grasp the concepts. We used the official Kentucky CDL Handbook to ensure that our information is relevant to ...

Printable Pre Trip Inspection Checklist (PDF) CDL Manual. CDL General Knowledge Practice Test. Pre Trip Inspection Practice Test. CDL HAZMAT Endorsement Practice Test. Edited for 2024 on 12/5/23. Complete CDL pre-trip inspection checklist with online reference and study guide plus a free PDF pre trip inspection checklist to print.

Learn how to pass your CDL pre trip test, and complete a pre-trip inspection as part of your licence test. Get Your INSPECTION CHECKLIST: https://www.smartdr...

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam. Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will ...

Real Kentucky CDL vehicle inspection test questions, 100% free. Pass your inspection test, take this KY vehicle inspection practice test now! ... The vehicle inspection test, formerly known as pre-trip, is a skills test to see if you identify which features and equipment on the test vehicle should be inspected before driving. During the test ...

What to expect on the actual KY CDL exam. 20 questions. 16 correct answers to pass. 80% passing score. Do you think you're prepared to take the KY CDL Pre-Trip Inspection Test? If you are not sure if you'll pass, it is a mistake to go to the DMV and sit for the exam. You could fail it, and that will make it hard for you to maintain your job.

HOW TO PASS A Class A Pre-trip inspection in 26 min. Conducted by DRIVE509 CDL SCHOOL. https://www.eldt.com/ CDL School Management software designed just f...

A video outlining the proper steps to completing a required pre-trip inspection for CDL drivers.

KENTUCKY CDL PRE-TRIP INSPECTION CHEAT SHEET . 1. During the pre-trip inspection: • You must show that the vehicle is safe to drive. 2. In addition to the standard inspection procedures for all vehicles, the driver of a coach/transit bus must also check the doors/mirrors to verify that: • Entry/exit doors are not damaged and operate ...

Pre-Trip inspection demonstrated on a school bus. This is how you should perform your pre-trip inspection on the CDL road test. This would be after you perfo...

Practical exams. Skills test. Pre-trip inspection. TSA background check. Retake policy. CDL Maintenance. ELDT Training & Certification. CDL how-to guides. Learn how to conduct thorough pre-trip inspections with our guide, a critical component for commercial vehicle safety.

Jeff from Apex CDL Institute is a licensed 3rd party CDL examiner in the state of Kansas. Here he demonstrates how to perform a proper pre-trip inspection on...