Mercedes Benz

Table of Contents

What is Suspension Travel?

In this brief article, we will discuss the Suspension Travel and the Suspension travel found in various types of suspension.

Suspension travel is defined as the maximum vertical distance that the wheel can travel from the fully extended ‘Rebound’ condition to the fully compressed ‘Full Bump’ condition.

‘Bump Travel’ is defined as the distance traveled by the wheel center from Normal ride height to Full Bump condition.

‘Rebound Travel’ is defined as the distance traveled by the wheel center from Normal ride height to Rebound condition.

The ‘Bump travel’ is limited by the provision of Bump stop rubber blocks that compress and stop further travel before metal-to-metal contact. In most cars, the ‘rebound travel’ is limited by rebound rubber buffers inside the shock absorbers that stop the wheel hubs from dropping beyond the fully extended length of the shock absorber.

How is Suspension travel calculated?

Suspension travel is mostly dependent on the stiffness of the spring selected for the suspension. While designing a suspension system, ideally, a spring stiffness should be selected:

- ‘Soft’ enough to give not too harsh a ride, but yet is

- ‘Stiff’ enough to absorb the energy of road shocks without hitting the bump stops too often.

Additionally, the springs must also be stiff enough to prevent excessive roll on corners, but this is not always required since roll stiffness can be specifically handled by the use of an anti roll bar and not increasing the spring stiffness.

The normal rule of thumb in design is to allocate:

- ⅔ of the total suspension travel to ‘Normal ride height -to- Full Bump’ and,

- ⅓ of the total suspension travel to ‘Normal ride height-to-Rebound’

How is Bump travel decided?

A rough rule is that the stiffness and bump travel have to be both selected such that the spring stiffness progressively increases and can take a load of ‘2g’ or twice the corner weight before the point of full-bump travel is reached. The intention is that, while driving on normal roads, the car suspension should not be continuously hitting against the bump stops, either due to too much softness in the springs or less bump travel. Bump stop hitting causes a great amount of discomfort to the occupants.

In order to control bump stop hitting is to make the spring slightly stiffer than its normal rate as the wheel gets closer to its upper limit, or bump stop. This is called ‘progressiveness’ of the spring rate. The progressiveness of the suspension rate can be achieved using

- A progressive coil spring

- A rubber bump stop buffer

Why is Rebound travel important?

Ideally, the suspension must allow the wheels to move up and down in such a way that they follow the unevenness of the road while maintaining the body to ride as level as possible.

So the Rebound travel should be such that the suspension is able to maintain tire-to-road contact at all times. The shock absorber rebound stop contact must be avoided, or, the wheels must not hang in air, since this is a source of discomfort to the occupants.

The rebound travel must also take into account vehicle roll during cornering. The inside tire during extreme cornering maneuvers must not lift off the ground. Tire lift off during cornering will drastically reduce lateral grip since grip is proportional to tire contact area and vertical load.

How much Suspension Travel do Cars have?

In most common street applications, the suspension travel ranges in the following manner:

Suspension travel is different for different vehicle applications:

- For Trucks and off-road vehicles, the suspension travel is usually 4” of travel from normal ride height to both bump and 4” inches of travel to rebound.

- For track applications 3” of travel from normal ride height to both bump and 2” inches of travel to rebound.

Is it possible to Increase suspension travel?

Yes, it is possible to achieve more suspension travel. The situation where this would be required is if you intend your vehicle to have Off-roading capability. In Off-Roading, a greater wheel articulation would help you tackle various sorts of uneven terrain.

But compared to Decreasing suspension travel, increasing suspension travel requires comparatively more modifications. What is basically needed is:

- Increased Normal ride height, or, the vehicle must sit higher when unladen

- Increased Rebound travel, or, the wheel must drop further downwards.

In order to achieve the above, you would need to replace your vehicle’s factory suspension with an aftermarket Off-Roading Kit. Depending on the vehicle you own, you would need to look for a supplier that has compatible parts. One important point to note is that your car/truck was designed by the OEM specifically for the current ride height. So changing this setup cannot be done using ready-to-fit parts. You would need to make several chassis/underbody modifications in order to achieve your goal.

Superlift, ReadyLift, Icon Vehicle Dynamics, BDS Suspension and Rough Country are some of the many brands available in the market.

If you are trying to Lift your truck suspension , then some of the changes that would be required to the vehicle would be

- Modified Cross members that lower the support position of the suspension brackets. This may require you to remove the chassis bracket and maybe cut and re-weld the aftermarket parts onto them. Make sure you have a really experienced person to do this as it is a high-precision job.

- Modified front differential mounting brackets (in the case of a 4X4 vehicle)

- Long-travel Shock absorbers to replace the OE parts

- Longer travel coil Springs (if your vehicle has coil springs)

- Modified higher camber and long-travel leaf springs (if your vehicle’s rear suspension has leaf springs)

- Modified anti-roll bar chassis mounts and drop-links. Since the wheels sit lower than the original position, the anti-roll bar’s position will also need to be lowered so that it can function properly at the new height.

- Before starting out on the modifications, you need to decide whether you are going to someday go back to the original OE setup or not.

- If you intend to put back the OE parts, you need to be mindful of the original parts and store them properly as a set. Also, you may not be able to reverse some of the cutting and welding that you may do during lifting. So you would need to replace original OE brackets in those cases.

Is it possible to Decrease Suspension Travel?

Yes, it is possible to Decrease Suspension travel, or in other words, lower the car. The most common reasons for doing this would be

- To make your car look cooler. It is a known fact that lowered cars give the impression of sportiness to anyone looking at it.

- To make the car functionally perform better on the race track.

There are several aftermarket parts suppliers to choose from, when it comes to getting your car lowered . You need to choose a reputed company that has experience in modifying your particular car model, or brand at least. Or the other way would be to source each of the best aftermarket replacement parts from multiple specialist suppliers who are experts in manufacturing a particular part, e.g Shocks might be a specialty of one company, while lowering springs would be a specialty of another manufacturer.

The changes that would be required are:

- Lowering Springs: The aftermarket lowering springs would be of shorter length and be of a higher and more progressive rate in order to make the suspension work within the reduced travel.

- Aftermarket Coilovers or shock absorbers: The new lowered stance would mean a higher spring rate with lesser travel. The original shock absorbers were tuned for comfort and more travel. The new shock absorbers would require a different damping ratio to account for the new springs. With a shorter spring, the suspension arm would be able to travel more into the bump, closer to the bump stop. This would require a shorter ‘shut height’ in the new shock absorber/Strut.

- Modified control arms of higher strength would be required since the bump stops would be hitting more number of times.

- Low Camber leaf spring and axle mounts: In the case of leaf springs, you would probably need a new set of springs and slimmer axle mounts.

- UnderSlung Axle: For a leaf spring suspension , if it was an overslung axle, there might be potential to convert it to an underslung using an aftermarket kit. The axle will sit above the spring, thus bringing the chassis closer to the ground

- Torsion Bar Key : For a Torsion bar suspension, lowering can be easily done without any additional aftermarket parts. The only thing to be done is to readjust the zero rotational position of the torsion bar.

After-effects to expect when Lowering the Suspension

- Poor or harsh ride quality

- Underbody scraping when going over bumps or steeply inclined driveways

In this brief article, we have discussed the Suspension Travel and the Suspension travel found in various types of suspension.

Related Posts

Can a sway bar link make noise, what are the best exhaust brands, is oe tuning worth it.

You are using an outdated browser. Please upgrade your browser to improve your experience.

- Product Lines

- Shoxs Suspension Seats

- Kinetix Impact Monitoring

- Accessories

- Military / Professional

- Recreational

- Seat Selection

- Custom Engineering

- Human Factors

- Performance Testing

- Whole Body Vibration

- About Shoxs

- Impact Science

- United Safety & Survivability Corporation 101 Gordon Drive Exton, PA 19341, United States

- 610-265-3610

- [email protected]

You have no items in your cart, add some on the products page .

- Find a Dealer

- 2024 Catalog

Suspension Travel

Shock size matters, more suspension travel results in a smoother ride.

Imagine a car speeding towards a brick wall. The average force (and acceleration) required to bring a moving body to rest is inversely proportional to the stopping distance. The ability of a shock-mitigating device to lessen an impact and ensure a smooth ride is tied to its stopping distance. It’s the equivalent of gently applying the brakes on the car, allowing it to roll to a halt over some distance.

Acceleration: Defined

We gain further insight by considering the definition of acceleration: the rate of change of velocity with respect to time. When a boat collides with a wave it undergoes a velocity change due to its motion relative to the water’s surface, and so the acceleration will depend on the size of that change and inversely depend on the time over which it occurs. This suggests the two main approaches to lowering impact severity: reduce the impact velocity or increase the time duration of the event.

Impact Factors on the Water

On the water, a boat’s hull design, speed, and the sea-state are the dominant factors that dictate the velocity change during a wave slam. This change is thus reduced by improved hull design, slowing down, and avoiding poor conditions. These preventative measures lie at the heart of any shock-reduction strategy, but impacts cannot be eliminated entirely. In certain cases, speed cannot be reduced, waves cannot be avoided, and even the most experienced operator can be caught off-guard.

Milder Rides

Shock mitigating equipment is designed to increase the time duration of each impact. The longer it takes to undergo the impact velocity change, the smoother the ride will be, and adding suspension travel to a shock-mitigating device is a sensible way to achieve this. It’s akin to giving the imaginary car more braking distance before the wall.

Comparing Suspension Travel Lengths

A longer deceleration leads to lower average forces. This explains why a 1” platform of vibration-mitigating foam is inferior to a 4” travel suspension system when it comes to mitigating shocks. Likewise, a 4” travel suspension will be outperformed by its 10” counterpart. The principle applies to impacts in any direction, including lateral. If only a short suspension travel distance is provided, a proportionate level of shock-mitigation can be expected.

Other Considerations

Of course, there are space and weight limitations on any boat, and ergonomics must be a top priority. Operators must interact with controls, maintain a low profile, and avoid sacrificing their sightlines. But when it comes to shock-mitigation, bigger really is better, and long-travel suspensions will yield the best results.

CarParts.com will be back soon!

We apologize for the inconvenience. The CP Team is working on some upgrades to improve our service. Thank you for using CarParts.com!

You can call us at

1-866-529-0412

Reference ID: 18.7fc733e.1711887560.54a089e2

INTRODUCTION TO SUSPENSION

Why do cars have suspension?

The object of a suspension system is to isolate the body and its occupants from the irregularities of the road surface. Ideally the body should ride level and without vertical motion’ however bumpy the road surface. Another important feature of suspension is that it should keep the tires on the ground all the time. If there were no suspension the tires would tend to lift off the ground every time they passed over a bump at the same time, the shock as the wheels left the ground’ and then came down again, would be transmitted directly to the passengers.

What does a suspension?

Ideally the suspension should allow the wheels to move up and down so that they follow the undulations in the road’ while the body rides level. The first requirement therefore is that the wheels should be able to move vertically relative to the body. Every suspension has this wheel travel, which must be accommodated by some means.

How is the wheel movement accommodated?

Springs are normally used (Figure 1.1). As the tire strikes a bump in the road, so a vertical force is applied to the spring’ which is compressed or deflected. Therefore the wheel moves vertically relative to the body, and the tire maintains contact with the road surface. However, some of this force is transmitted through the spring to the body, which also tends to rise. If the springs are very ‘soft’ (i.e. have relatively low spring rates) the body rises little, but if the springs are very stiff the body rises quite a bit, depending on the severity of the bump. For a good ride, therefore, the springs should be soft.

Do soft springs have any disadvantages?

Although soft springs give a good ride in most circumstances, they allow the body to roll a lot during cornering. In practice, spring rates are a compromise between the requirements of ride and handling.

Why does a car roll?

When a car turns a corner, centrifugal force acts on the body and tends to push it outwards. However, this force is resisted by the tires, which grip the road; as a result, the body rolls about its suspension (Figure 1.2).

What is the disadvantage of roll?

When the car rolls excessively it is more difficult for the driver to control its direction. Also, when the car emerges from the corner and the body rolls back to the upright position, it will roll past the upright position if roll is excessive, and will take some time to right itself. Excessive roll can also make the wheels adopt unfavorable angles, depending on the type of suspension fitted.

Are any other components needed?

In its simplest form the suspension consists purely of the springs and their anchorages. However, when a spring is deflected it attempts to return to its normal position immediately, and if left to itself it goes past the normal position and then back again. It would take a number of these oscillations absorb the stored energy, and only then would the spring return to the normal position.

How is spring oscillation controlled?

Dampers are used to cut down these oscillations so that, after going past the normal position once, the spring soon returns to normal.

SPRINGING REQUIREMENTS

What are the basic requirements of a spring?

Ideally a spring should be arranged so that it is ‘soft’ enough to give a good ride; yet it should be able to absorb all the energy resulting from road shocks without using up all the wheel travel, and it should be stiff enough to prevent excessive roll on corners.

Are all these possible?

Suspension is a compromise between conflicting requirements, but it is possible to gain a good level of performance in all respects, although this can be expensive. First, however, it is necessary to appreciate how these parameters are measured, and how the important figures are calculated.

How is the ‘softness’ of a spring measured?

Every spring has a rate, which is an indication of how much the spring is deflected by load. This is normally indicated as load per unit deflection, given in Newton ’s per millimeter (or pounds-force per inch). However, when it comes to ride, the weight being carried has to be taken into account as well as the spring rate. For example, if a small mass is applied to a spring there is hardly any deflection, whereas a big mass applied to the same spring will give a big deflection, lithe mass is then bounced on the spring, the small mass moves very little, very quickly, whereas the big mass moves up and down quite a long way, but slowly. The amount the mass deflects the spring is called the static deflection, and the rate at which the mass bounces up and down is the natural frequency or periodicity of the spring-mass system.

How is the static deflection found?

The static deflection, D mm, is simply the mass carried divided by the spring rate, i.e. D = mass/spring rate.

How is the natural frequency found?

This is a bit more involved, in that the natural frequency = 30/ cycles/mm, where D is the static deflection, in meters.

What are typical values?

Values vary according to the type of car. For a small saloon the static deflection is often 110-140 mm, and the equivalent natural frequency between 90 and 80 cycles/mm. For a medium-size saloon, the figures might be 130-180 mm, between 85 and 70 cycles/mm; for a large saloon, 180-280 mm, between 70 and 55 cycles/mm. With some very advanced suspensions, figures of over 280 mm or under 55 cycles/mm are obtained.

Do these figures vary with load?

The actual figures for a car vary according to the load carried. When the car is in the kerb condition the frequencies will normally be higher than when it is fully laden, with four people and their luggage in the car. Also, there is normally little difference in the amount of weight carried by the front springs, laden or unladen, but a big difference at the back.

Typical figures for a medium-size saloon are

At the front the difference is small enough to be ignored, but at the rear it makes the ride firmer unladen than when fully laden. Ideally the frequency should remain constant, irrespective of loading, and at a satisfactorily low level.

Can a constant frequency be obtained?

A constant frequency can be obtained only if the spring rate increases in proportion as the load it carries increases. Of course the balance can also be improved by arranging for the increase in weight to be applied equally to the front and rear springs. In practice this is very difficult to arrange.

How is the stiffness of the spring measured in roll?

Basically, the stiffer the spring, the less the car will roll, although the spacing of the springs and the roll-centre height also affect the amount the car rolls. The roll stifThess, which is the measure of the way in which the springs resist roll, is given by:

Roll stiffness = C w x t x 0.08729 N m/deg

for independent suspensions, where C w is the spring rate at the wheel, known as the wheel rate, and t is the track of the car. For beam-axle suspensions:

Roll stiffness = Cs x s 2 x 0.08729 N m/deg

where C s is the spring rate, and s is the spring base, i.e. distance between the effective positions of the left- and right-hand springs.

In simple terms, this means that an increase in either the spring rate or the spring base (or track) will increase resistance to roll, and that more can be gained by increasing the spring base (or track) than by increasing the spring rate.

How can the spring base be increased?

With a beam axle, the spring base is the distance between the springs (Figure 3.1), and the practical width is determined by the necessity of giving clearance around the wheels and brakes.

In practice, this means that the spring base is about 70-80 percent of the track, and that the wheel rate in roll is only about 50-70 per cent of the wheel rate in bump. There is little that can be done to increase the spring base with beam axles.

Is independent suspension better, then?

A better balance between ride and roll stiffness can be obtained with independent suspension, because the wheel rate in bump is the same as it is in roll. So, assuming that the linkages are equally good and that the roll centre of the independent suspension is not very low (see later), independent suspension has this one definite advantage.

Can roll stiffness be increased in any other way?

The addition of an anti-roll bar increases roll stiffness and reduces roll. An anti-roll bar is a horizontal, transverse torsion bar, normally mounted in two rubber bushes on the body. The ends are turned round to form levers, and are attached to the suspension member or axle, either directly or through drop-links. When the front wheels strike an undulation in the road so that both springs are deflected, the anti-roll bar merely rotates, so it is not deflected and exerts no force on the body. However, when the car goes round a corner, and rolls, one lever goes upwards and the other downwards, so the anti-roll bar is twisted. The bar resists, and tries to twist the car body back to the vertical position. Generally, then, the .addition of an anti-roll bar reduces roll but does not affect the ride. The stiffness of an anti-roll bar is usually referred to as its spring rate in roll.

Does the anti-roll bar have any side effects?

Quite often only one wheel hits a bump, and in this case the anti-roll bar does alter the spring rate. What happens is that the anti-roll bar twists as the wheel is raised but, since the other wheel does not move, the bar twists over its whole length (in roll, the bar is twisted from both ends, as it were, so its effective length is half the actual length). This situation, called single-wheel bump, has a higher bump rate than when both wheels move upwards together. For example, if the spring rate of the anti-roll bar is 7 N/mm and the wheel rate of the spring is 20 N/mm, then on single- wheel bump the rate is 20 + 7/2 = 23.5 N/mm. If the proportions are of this order, the passenger will hardly notice the difference. However, if the spring rate is very low and the anti- roll bar is very stiff, a single-wheel bump will tend to rock the car, inducing what is called a roll-rock condition, which can be uncomfortable.

Can the resistance to roll be altered in any other way?

Although the roll stiffness depends purely on the spring rate in roll, the anti-roll bar and the spring base, the resistance to roll also depends on the roll centre. But in essence the higher the roll centre, the less the vehicle rolls. Why does a high rod centre reduce roll?

When a vehicle corners, the centrifugal force acts through the centre of gravity, and it is this that makes the vehicle roll. However, if we consider the front of the car (i.e. the front wheels, and the amount of the car they carry), then the body or portion of the body must roll about some point, and that is the roll centre (Figure 3.2). The force making the vehicle roll is called the tilting moment, which is the tilting force times its effective height. The effective height is the distance, h, from the centre of gravity of the vehicle to the roll centre. Therefore, to reduce roll, h should be kept to the minimum. If the two were at the same height, the car would not roll at all. It is for this reason that the centre of gravity of a racing car is as low as possible.

Apart from the problems with roll, are there any other limitations on how soft the springing can be?

Even if roll could be kept to the minimum by the use of unusual suspension geometry and anti-roll bars, there are limitations on how soft the springing can be. The main limitation is the need to absorb all the energy applied to the spring by road shocks without the spring ‘crashing through’. For example, let us assume that a spring has 76 mm of movement from the normal laden condition to full bump, and that the spring rate is 18 N/mm. Therefore, to compress the spring fully (or make it crash through), 1350 N must be applied by a bump in the road; the force will depend on the severity of the bump and the speed of the car, but loads of 890-1100 N can be applied quite often. Now, consider a car with a same amount of wheel travel, and a very soft suspension, with spring rates of only 10 N/mm. A force of 760 N would take up all the wheel travel (10 N/mm x 76 mm = 760 N; so if a force of 890 N were applied, not only would the springs be fully compressed, but a force 130 N would be applied to the body. That would jolt the car, and also create quite a noise.

Why cannot the wheel travel be increased?

More wheel travel can be incorporated to alleviate this problem, but there are a number of problems. First, the wheel arches have to be made taller to allow clearance for the wheels, and this can reduce passenger or luggage space. Secondly, the springs and dampers have to be longer, and there may be little room for them (especially in low cars). Thirdly, it is difficult to arrange for the suspension to give suitable wheel control for large suspension travel.

How much wheel travel can be provided?

It is normal for there to be about 75-100 mm from normal laden to full bump; up to

150 mm is practical, especially on big cars.

How else can ‘crash-through ‘be avoided?

The use of springs with progressive rates and self-leveling systems can allow the use of softer springs without the need for a lot of wheel travel. A spring with a progressive rate is one in which the rate increases as the spring is deflected. In the normal laden condition the rate might be 14 N/mm, after 25 mm of extra compression it might be 18 N/mm, and at fill bump after 75 mm of compression it might be 25 N/mm. Thus, although the rate at the normal laden condition might be lower than in our original example, the load needed to compress the spring fully would be slightly higher.

What does a leveling system do?

A leveling system allows a car to ride at the same height irrespective of its loading. Usually it is hydraulic, and as the load increases (as people get in, or as luggage is put in the boot) and the rear of the car goes down, so the hydraulic system pumps the hydraulic struts up, raising the rear of the car to the original height. Equally, when someone gets out and the car rises a little on its suspension, the system removes fluid so that the car falls to its correct level.

What is the advantage of self-leveling?

The suspension has to be designed to suit the car when the driver is alone, when there are two, three or four people in it, and when there is some luggage in the boot as well. With a normal suspension, every time someone gets in, the springs are compressed a little. So when the driver is alone, there might be 1 15 mm bump travel, gradually reducing to about 75 mm when the car is laden normally, and perhaps only 50 mm when fully laden. There must also be some rebound travel to allow the wheel to fall down below the normal position, for instance when the wheel goes over a pothole. Therefore, there might be 150 mm wheel travel (normally 75 mm bump and 75 mm rebound) but filly laden, when the bump travel is most needed, there would be only 0 mm travel. Now, with self-leveling there might still be 150 mm of wheel travel, but there would always be 88 mm bump travel and 62 mm rebound travel, for example. Not only does the car look better, because it always rides level, but there is effectively more suspension travel available, so softer springs can be used.

Is the amount of rebound travel important?

It is essential that the suspension has sufficient rebound travel, too little being a common fault with many earlier cars. In the first place, if the wheel is able to fall sufficiently to keep in contact with the road when it encounters a depression in the road surface, the ride is much more comfortable and there are less shock loads than if the wheel is hanging in mid-air for part of the time. But rebound travel is extremely important on cornering: when a car corners the body rolls, so as far as the suspension is concerned it is as if the inner wheel goes on rebound, and the outer wheel on bump. If there is insufficient rebound travel, the inside wheel will become airborne at reasonably high cornering speeds, thus reducing the cornering power. To keep some load on the inner wheel when cornering, at least 62 mm of rebound travel is needed.

What is the ideal suspension?

An ideal suspension would have very low frequencies in order to give a good ride, but would have the aid of progressive-rate springs so that the frequency remained constant irrespective of load. There would also be self-leveling, and the linkage would be designed to give high roll centers so that there would be little roll and anti-roll bars would not be needed. To go further, the suspension would need to be designed so that every bump or ripple in the road was detected before it was reached; a signal would then make the wheel move to allow for the bump, so that the tire maintained contact with the road surface at all times, with the car riding level.

Why are dampers needed?

Whenever the tire passes over a bump of any magnitude the springs are deflected. The amount of deflection depends on the size of the bump, and the speed and weight of the car. When the spring stops deflecting, it has a store of force equivalent to the spring rate and the deflection: with an 18 N/mm spring, and a deflection of 25 mm, the energy is 18 x 25 = 450 N. This energy than pushes the wheel downwards, and if there were no damping the car would continue to oscillate up and down on its springs for a long time. To prevent this continuous oscillation, dampers are fitted.

How does the damper cut out these oscillations?

The damper offers a resistance to any motion of the suspension. Therefore when the spring is deflected both the damper and the spring resist deflection; on rebound the damper again resists deflection, but this time it opposes the force exerted by the spring.

Should the damper exert the same force on bump and rebound?

Since the damper opposes the spring action only on rebound, the force it exerts should be greater then than on bump. In any case, if the damper exerts a large force on bump it just makes the ride harsher. Ideally, therefore, the damping force should be small on bump and large on rebound.

Should the damping force vary with speed?

On bump, the speed at which the suspension is deflected depends on the conditions, and can vary quite a lot. Therefore the resistance should increase as the speed increases. The rate at which the suspension extends on rebound remains constant, and depends on the natural frequency of the suspension, so the damping should exert a constant force. This will be achieved if the damping force is proportional to speed.

What would be ideal damping?

On a car, damping is a compromise between ride and handling. For a comfortable ride, damping should be very light on bump; on rebound it should be light enough to allow the car to traverse small bumps without any harshness, but stiff enough to control the amount of oscillations after each bump so that the car does not wallow. For handling, the car should have the minimum number of oscillations, so that the car does not float. However, if the dampers are very stiff they will apply very high initial forces when a car is turned into a corner, and this can also upset the cornering.

What form do dampers take?

On the earliest cars there were no dampers, and interleaf friction and friction at the suspension anchorages provided the only form of damping. However, since the springs were very stiff, and hardly deflected at all, the absence of damping was not too obvious. Later, when some attempts were made to make suspension softer, it was found that damping was needed, and friction dampers were introduced. These took the form of a number of friction discs clamped together and connected by levers to the suspension so that, as the wheels moved up and down, the friction faces rubbed against one another. These were not very consistent in operation, and gave identical damping on bump and rebound-which is not ideal, of course. The energy was converted into heat as the discs rubbed together; even in hydraulic dampers the energy is dissipated in the form of heat.

How does a hydraulic damper work?

The basic principle is that a piston moves up and down with the suspension, and as it does so forces fluid through a hole or a number of small holes. Because the holes have a small area, there is a substantial resistance to the movement of the piston. Obviously, the basic ‘hardness’ of the dampers depends on the area of the holes.

ANTI- ROLL BARS

Are anti-roll bars fitted to many cars?

A large number of modern saloon, estate and sports cars are fitted with anti-roll bars, both to reduce roll and to give the desired road holding characteristics. On racing cars, different diameter anti-roll bars are used for different circuits, and the links are arranged so that the length of the effective lever can be altered.

How does an anti-roll bar alter the handling characteristics?

The anti-roll bar reduces roll by increasing the spring rate in roll only-the roll rate or roll stiffness. Therefore, if an anti-roll bar is added to a suspension at one end only it alters the front-rear roll stiffness ratio, and this alters the handling characteristics. As a general rule, if an anti-roll bar is added only to the front suspension the car will under steer more, and if one is added only to the back the car will over steer more.

What characteristics are best, and where does the anti-roll bar come in?

For normal use, it is desirable that a car should under steer (but not excessively), since this is a much more stable condition, especially near the straight-ahead position. The trend in the 1960s was to use anti-roll bars only at the front to obtain the desired under steer, but more recently the trend has been to fit anti-roll bars at front and rear, although with a much stiffer bar at the front. Under steer is still the aim, but with less roll and less under steer than on some of the cars of the late 1950s and early 1960s.

What is the roll centre?

The roll centre is the point about which the car rolls when it corners. There is a roll centre at the front and one at the rear, and a line joining the two points is the roll axis- the axis about which the car rolls.

What fixes the height of the roll centre?

With a beam axle it is the links providing lateral location that determine the height of the roll centre. Thus with leaf springs, the roll centre is at the height of the spring anchorages; with a Panhard rod, at the point where the rod is connected to the axle; with the Watts linkage, at the fixing of the link to the axle. See Figure 9.5.

How much can these heights be varied?

The roll-centre height with a Panhard rod can be altered quite a lot, depending on how much room there is under the body. The Watts linkage gives a roll centre within a few inches of the height of the axle, since it cannot be installed very low or very high. With the conventional four-link arrangement the roll centre is above the axle height, although it is possible to fit the splayed links or the A-bracket below the axle, in which case the roll centre can be quite low.

How high should the roll centre be?

The height of the roll centre is dictated by the characteristics required, the distance between the springs on the axle-the spring base-and the characteristics of the front suspension. In most cases, though, the roll centre needs to be fairly high.

What difference does the height of the roll centre make?

The higher the roll centre, the less the car rolls; if the roll centre is above the centre of gravity of the car, the car will roll inwards on corners! Very high roll centers can give some undesirable characteristics but, since the effective spring base at the rear is almost always quite a lot less than at the front, a higher roll centre at the rear is needed to give good handling characteristics.

Are there any other important points about roll-centre heights?

When the car rolls, or goes down on the springs, it is important that the height of the roll centre should not vary too much. Apart from the four-link suspension, the roll centers of all these suspensions remain substantially constant when the car rolls or pitches. The variation in height with the four-link system is not normally sufficient to create problems, however.

What is roll steering?

Roll steering occurs when the vehicle rolls; as a result of the roll, the wheels are moved so that they are not parallel with the body longitudinally. Semi-trailing links, some combinations of double-link suspension with radius rods, and some linkages for beam axles give roll steering.

Let us consider a beam axle, located by a pair of radius rods, parallel to the car, but inclined upwards from the axle to the body. Now, when the car goes over a bump, and the axle moves upwards relative to the body, the radius rods will move to the horizontal. This lengthens the wheelbase, which is not critical in itself. However, when the vehicle rolls, one wheel will go up and the other down relative to the body. As a result, on the side where the wheel has gone up the wheelbase will have been lengthened, while on the side where the wheel has gone down the wheelbase will have shortened slightly. Therefore the axle will have turned relative to the body, steering it- hence roll steering. In this case, if we are looking at a rear axle, the wheels will be steering outwards relative to the corner, giving roll oversteer. If the rods were inclined upwards in the normal condition, then roll undersreer would result. At the front, roll steering usually results from geometrical inaccuracies in the steering linkage, so that as the car rolls the steering arm is pulled inwards or pushed outwards by the tie-rod. If there is any roil steering in the linkage it should be roll under steer, since this is inherently safe, but roll steering should be avoided if possible.

APPENDIX: SUSPENSION FORMULAE

b is the width of the spring blade (m), L is the distance between the eyes of the spring when laden (m), t is the thickness of the blade (m), n is the number of blades, and E is the modulus of elasticity, which (modified to allow for internal friction) is 159 x 106 kN/m 2 .

For a torsion bar, the spring rate is given as the twisting moment per angular deflection. When a lever is added, this can be converted into a rate for the vertical deflection of the end of the lever.

Spring rate (torsion bar, for deflection at end of lever)

G is the modulus of rigidity, which is 78.5 x 106 kN/m 2 in this case, d is the diameter of the torsion bar (m), l is the effective length of the torsion bar (m), i.e. half the length of the bar for an anti-roll bar, and e is the length of the lever (m). Spring rate (coil spring)

G is the modulus of rigidity, which is 81.5 x 106 in this case, d is the wire diameter (m), n is the number of free coils, and D is the mean coil diameter (m).

To find the number of free coils it is necessary to subtract the number of dead coils from the total number of coils. The dead coils are those that provide the abutment and so cannot be deflected, usually 1.5 to 2 coils.

Roll stiffness (independent suspension)

= C w x t 2 x 0.8729 N/deg

C w is the spring rate at the wheel, i.e. wheel rate (N/mm), and t is the vehicle track (m).

Roll stiffness (beam axle)

= C s x s 2 x 0.8729 N/deg

C s is the actual spring rate (N/mm), and s is the spring track (m).

The wheel rate is not the same as the spring rare, and depends on the effective leverage, or the separation of the springs relative to the track. Thus if the distance from the centre-line of the car to the spring on a beam axle is a, and the distance from the centre-line of the car to the centre-line of the wheel (i.e. half the track) is b, as shown in (Figure A.l (a)), then:

Wheel rate C w = C s x (a 2 /b 2 ) N/mm

With independent suspension the formula is similar, except that b is the length of the suspension arm and a is the distance from its pivot to the axis of the spring (Figure A.l (b)). With double-wishbone suspension the formula is modified to take into account the effects of the other wishbone on the geometry. The formula becomes:

Wheel rate C w = (C s x a 2 x c 2 ) /(b 2 x d 2 ) N/mm

where a,b,c and d are as shown in Figure A.2.

DSPORT Magazine

Automotive Performance + Tech Magazine

SUSPENSION 101: Everything You Wanted To Know About Vehicle Handling

Making your car handle well is a really complicated task if you overthink it. Ride frequencies, roll centers, camber curves, scrub radii; it’s enough to make you build show cars instead. So, I have an easy solution for you: ignore all of that stuff. Odds are that you can make your car handle better than most by knowing the following five things.

Text by Dave Coleman // Photos by DSPORT Staff

DSPORT Issue #148

Number One: Tires

What about treadwear rating? You might be thinking, “Isn’t a tire with a treadwear rating of 40 far grippier than one with a 400?” That’s probably true. The treadwear rating is a decent indicator of a tire’s performance capability, but don’t nitpick it. A 160 treadwear is not necessarily stickier than a 200. The more modern a tire design, the higher its treadwear rating can be while still being sticky. In fact, the Uniform Tire Quality Grade Standards (UTQG) treadwear rating is actually the minimum treadwear of that specific tire. It’s at the manufacturer’s discretion whether they want to classify a high performance tire as a “100” treadwear tire for marketing purposes even though it may offer enough tread life to be comparable to a “200” treadwear tire. Don’t waste your time comparing treadwear ratings between manufacturers, as every tire company hires its own independent testing company to conduct the tire tests. Unless any inconsistencies come up in the final data, the Department of Transporation doesn’t bother to regulate.

In the end, experience is the best tool for picking a tire. If you don’t have enough experience, use somebody else’s. See who is fast at the track and ask what tires they like, and why.

Number Two: Travel

Having enough suspension travel is almost as important as having good tires. Think about this when you’re fantasizing about how low you want your car to be. Some cars, like the old double-wishbone Civics, have so much travel that you can be in the weeds and still have plenty of travel. Others, like the MAZDASPEED3, can hardly be lowered at all before they start pounding the bump stops.

How much travel you need is determined partly by the terrain you’re driving on and partly by your suspension setup. Having stiffer springs means your suspension will move less, so you don’t need as much travel. The same is true if you have a lot of low-speed damping from your shocks. The next item might not be so obvious: you’ll need more travel and/or a stiffer suspension if you have really sticky tires. The reason is simple; more grip on the road means more body roll, which uses up more travel.

There are ways to maximize the amount of usable suspension travel range that involve adding more parts and making more changes to the entire system to balance out all the other dynamic factors. The simplest travel solution, though, is simply not to lower your car so much.

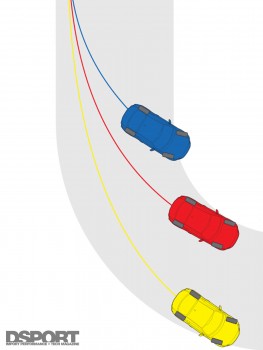

The red Miata shows excessive body roll with factory suspension. The blue Miata equipped with coilovers shows reduced body roll.

Article continued on page 2 >>>.

Advertisement

How Car Suspensions Work

- Share Content on Facebook

- Share Content on LinkedIn

- Share Content on Flipboard

- Share Content on Reddit

- Share Content via Email

When people think of automobile performance, they normally think of horsepower , torque and zero-to-60 acceleration. But all of the power generated by a piston engine is useless if the driver can't control the car. That's why automobile engineers turned their attention to the suspension system almost as soon as they had mastered the four-stroke internal combustion engine.

The job of a car suspension is to maximize the friction between the tires and the road surface, to provide steering stability with good handling and to ensure the comfort of the passengers. In this article, we'll explore how car suspensions work, how they've evolved over the years and where the design of suspensions is headed in the future.

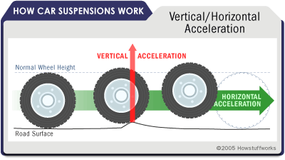

If a road was perfectly flat, with no irregularities, suspensions wouldn't be necessary. But roads are far from flat. Even freshly paved highways have subtle imperfections that can interact with the wheels of a car. It's these imperfections that apply forces to the wheels. According to Newton's Laws of Motion , all forces have both magnitude and direction . A bump in the road causes the wheel to move up and down perpendicular to the road surface. The magnitude, of course, depends on whether the wheel is striking a giant bump or a tiny speck. Either way, the car wheel experiences a vertical acceleration as it passes over an imperfection.

Without an intervening structure, all of the wheel's vertical energy is transferred to the frame, which moves in the same direction. In such a situation, the tires can lose contact with the road completely. Then, under the downward force of gravity , the tires can slam back into the road surface. What you need is a system that will absorb the energy of the vertically accelerated wheel, allowing the frame and body to ride undisturbed while the tires follow bumps in the road.

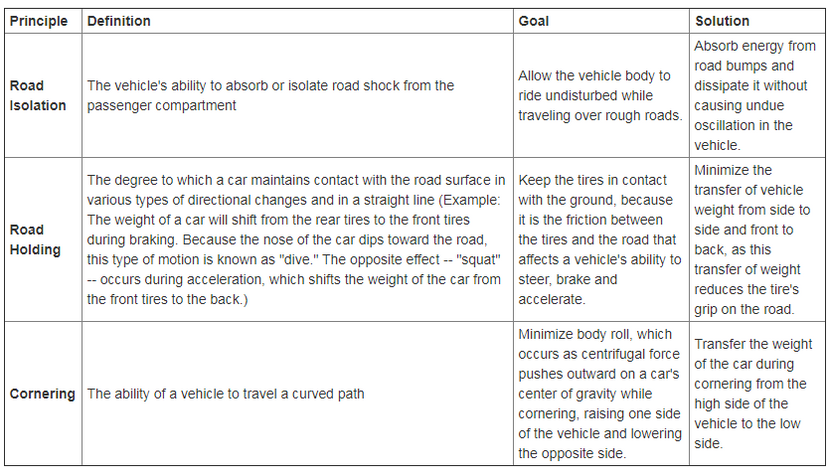

The study of the forces at work on a moving car is called vehicle dynamics , and you need to understand some of these concepts in order to appreciate why a suspension is necessary in the first place. Most automobile engineers consider the dynamics of a moving car from two perspectives:

- Ride : a car's ability to smooth out a bumpy road

- Handling : a car's ability to safely accelerate, brake and corner

These two characteristics can be further described in three important principles — road isolation , road holding and cornering . The table below describes these principles and how engineers attempt to solve the challenges unique to each.

A car's suspension, with its various components, provides all of the solutions described.

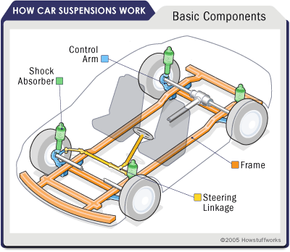

Let's look at the parts of a typical suspension, working from the bigger picture of the chassis down to the individual components that make up the suspension proper.

Car Suspension Parts

Dampers: shock absorbers, dampers: struts and sway bars, suspension types: front, suspension types: rear, specialized suspensions: the baja bug, specialized suspensions: formula one racers, specialized suspensions: hot rods.

The suspension of a car is actually part of the chassis, which comprises all of the important systems located beneath the car's body. These systems include:

- The frame : structural, load-carrying component that supports the car's engine and body, which are in turn supported by the suspension

- The suspension system : setup that supports weight, absorbs and dampens shock and helps maintain tire contact

- The steering system : mechanism that enables the driver to guide and direct the vehicle

- The tires and wheels : components that make vehicle motion possible by way of grip and/or friction with the road

So the suspension is just one of the major systems in any vehicle.

With this big-picture overview in mind, it's time to look at the three fundamental components of any suspension: springs, dampers and sway bars.

Today's springing systems are based on one of four basic designs:

- Coil springs are the most common type of spring and is, in essence, a heavy-duty torsion bar coiled around an axis. Coil springs compress and expand to absorb the motion of the wheels.

- Leaf springs consist of several layers of metal (called "leaves") bound together to act as a single unit. Leaf springs were first used on horse-drawn carriages and were found on most American automobiles until 1985. They are still used today on most trucks and heavy-duty vehicles.

- Torsion bars use the twisting properties of a steel bar to provide coil-spring-like performance. This is how they work: One end of a bar is anchored to the vehicle frame. The other end is attached to a wishbone, which acts like a lever that moves perpendicular to the torsion bar. When the wheel hits a bump, vertical motion is transferred to the wishbone and then, through the levering action, to the torsion bar. The torsion bar then twists along its axis to provide the spring force. European carmakers used this system extensively, as did Packard and Chrysler in the United States, through the 1950s and 1960s.

- Air springs consist of a cylindrical chamber of air positioned between the wheel and the car's body, and use the compressive qualities of air to absorb wheel vibrations. The technology is used in many luxury vehicles today, but the concept is actually more than a century old and could be found on horse-drawn buggies. Air springs from this era were made from air-filled, leather diaphragms, much like a bellows; they were replaced with molded-rubber air springs in the 1930s.

Based on where springs are located on a car — i.e., between the wheels and the frame — engineers often find it convenient to talk about the sprung mass and the unsprung mass .

Springs: Sprung and Unsprung Mass

The sprung mass is the mass of the vehicle supported on the springs, while the unsprung mass is loosely defined as the mass between the road and the suspension springs. The stiffness of the springs affects how the sprung mass responds while the car is being driven. Loosely sprung cars, such as luxury cars (think Mercedes-Benz C-Class), can swallow bumps and provide a super-smooth ride; however, such a car is prone to dive and squat during braking and acceleration and tends to experience body sway or roll during cornering. Tightly sprung cars, such as sports cars (think Mazda Miata MX-5), are less forgiving on bumpy roads, but they minimize body motion well, which means they can be driven aggressively, even around corners.

So, while springs by themselves seem like simple devices, designing and implementing them on a car to balance passenger comfort with handling is a complex task. And to make matters more complex, springs alone can't provide a perfectly smooth ride. Why? Because springs are great at absorbing energy, but not so good at dissipating it. Other structures, known as dampers , are required to do this.

Unless a dampening structure is present, a car spring will extend and release the energy it absorbs from a bump at an uncontrolled rate. The spring will continue to bounce at its natural frequency until all of the energy originally put into it is used up. A suspension built on springs alone would make for an extremely bouncy ride and, depending on the terrain, an uncontrollable car.

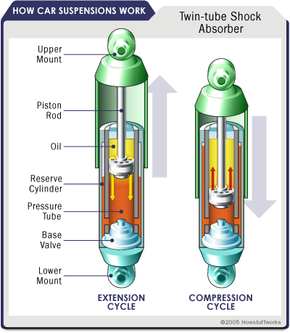

Enter the shock absorber , or snubber, a device that controls unwanted spring motion through a process known as dampening . Shock absorbers slow down and reduce the magnitude of vibratory motions by turning the kinetic energy of suspension movement into heat energy that can be dissipated through hydraulic fluid. To understand how this works, it's best to look inside a shock absorber to see its structure and function.

A shock absorber is basically an oil pump placed between the frame of the car and the wheels. The upper mount of the shock connects to the frame (i.e., the sprung weight), while the lower mount connects to the axle, near the wheel (i.e., the unsprung weight). In a twin-tube design , one of the most common types of shock absorbers, the upper mount is connected to a piston rod, which in turn is connected to a piston, which in turn sits in a tube filled with hydraulic fluid. The inner tube is known as the pressure tube, and the outer tube is known as the reserve tube. The reserve tube stores excess hydraulic fluid.

When the car wheel encounters a bump in the road and causes the spring to coil and uncoil, the energy of the spring is transferred to the shock absorber through the upper mount, down through the piston rod and into the piston. Holes perforate the piston and allow fluid to leak through as the piston moves up and down in the pressure tube. Because the holes are relatively tiny, only a small amount of fluid, under great pressure, passes through. This slows down the piston, which in turn slows down the spring.

Shock absorbers work in two cycles — the compression cycle and the extension cycle . The compression cycle occurs as the piston moves downward, compressing the hydraulic fluid in the chamber below the piston. The extension cycle occurs as the piston moves toward the top of the pressure tube, compressing the fluid in the chamber above the piston. A typical car or light truck will have more resistance during its extension cycle than its compression cycle. With that in mind, the compression cycle controls the motion of the vehicle's unsprung weight, while extension controls the heavier, sprung weight.

All modern shock absorbers are velocity-sensitive — the faster the suspension moves, the more resistance the shock absorber provides. This enables shocks to adjust to road conditions and to control all of the unwanted motions that can occur in a moving vehicle, including bounce, sway, brake dive and acceleration squat.

Another common dampening structure is the strut — basically a shock absorber mounted inside a coil spring. Struts perform two jobs: They provide a dampening function like shock absorbers, and they provide structural support for the vehicle suspension. That means struts deliver a bit more than shock absorbers, which don't support vehicle weight — they only control the speed at which weight is transferred in a car, not the weight itself.

Because shocks and struts have so much to do with the handling of a car, they can be considered critical safety features. Worn shocks and struts can allow excessive vehicle-weight transfer from side to side and front to back. This reduces the tire's ability to grip the road, as well as handling and braking performance.

Sway bars (also known as anti-roll bars) are used along with shock absorbers or struts to give a moving automobile additional stability. A sway bar is a metal rod that spans the entire axle and effectively joins each side of the suspension together.

When the suspension at one wheel moves up and down, the sway bar transfers movement to the other wheel. This creates a more level ride and reduces vehicle sway . In particular, it combats the roll of a car on its suspension as it corners. For this reason, almost all cars today are fitted with sway bars as standard equipment, although if they're not, kits make it easy to install the bars at any time.

So far, our discussions have focused on how springs and dampers function on any given wheel. But the four wheels of a car work together in two independent systems — the two wheels connected by the front axle and the two wheels connected by the rear axle. That means that a car can and usually does have a different type of suspension on the front and back.

Much is determined by whether a rigid axle binds the wheels or if the wheels are permitted to move independently. The former arrangement is known as a dependent system , while the latter arrangement is known as an independent system . In the following sections, we'll look at some of the common types of front and back suspensions typically used on mainstream cars.

Dependent Front Suspensions

Dependent front suspensions have a rigid front axle that connects the front wheels. Basically, this looks like a solid bar under the front of the car, kept in place by leaf springs and shock absorbers. Common on trucks, dependent front suspensions haven't been used in mainstream cars for years.

Independent Front Suspensions

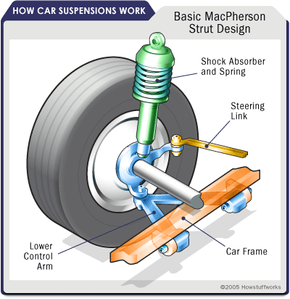

In this setup, the front wheels are allowed to move independently. The MacPherson strut , developed by Earle S. MacPherson of General Motors in 1947, is the most widely used front suspension system, especially in cars of European origin.

The MacPherson strut combines a shock absorber and a coil spring into a single unit. This provides a more compact and lighter suspension system that can be used for front-wheel drive vehicles.

The double-wishbone suspension , also known as an A-arm suspension or control-arm suspension, is another common type of front independent suspension.

While there are several different possible configurations, this design typically uses two wishbone-shaped arms to locate the wheel. Each wishbone, which has two mounting positions to the frame and one at the wheel, bears a shock absorber and a coil spring to absorb vibrations. Double-wishbone suspensions allow for more control over the camber angle of the wheel, which describes the degree to which the wheels tilt in and out. They also help minimize roll or sway and provide for a more consistent steering feel. Because of these characteristics, the double-wishbone suspension is common on the front wheels of larger cars.

Now let's look at some common rear suspensions.

Dependent Rear Suspensions

If a solid axle connects the rear wheels of a car, then the suspension is usually quite simple — based either on a leaf spring or a coil spring. In the former design, the leaf springs clamp directly to the drive axle. The ends of the leaf springs attach directly to the frame, and the shock absorber is attached at the clamp that holds the spring to the axle. For many years, American car manufacturers preferred this design because of its simplicity.

The same basic design can be achieved with coil springs replacing the leaves. In this case, the spring and shock absorber can be mounted as a single unit or as separate components. When they're separate, the springs can be much smaller, which reduces the amount of space the suspension takes up.

Independent Rear Suspensions

If both the front and back suspensions are independent, then all of the wheels are mounted and sprung individually, resulting in what car advertisements tout as "four-wheel independent suspension." Any suspension that can be used on the front of the car can be used on the rear, and versions of the front independent systems described in the previous section can be found on the rear axles. Of course, in the rear of the car, the steering rack — the assembly that includes the pinion gear wheel and enables the wheels to turn from side to side — is absent. This means that rear independent suspensions can be simplified versions of front ones, although the basic principles remain the same.

Next, we'll look at the suspensions of specialty cars.

Sixteenth-century wagons and carriages tried to solve the problem of "feeling every bump in the road" by slinging the carriage body from leather straps attached to four posts of a chassis that looked like an upturned table. Because the carriage body was suspended from the chassis, the system came to be known as a "suspension" — a term still used today to describe the entire class of solutions. The slung-body suspension was not a true springing system, but it did enable the body and the wheels of the carriage to move independently. Semi-elliptical spring designs, also known as cart springs, quickly replaced the leather-strap suspension. Popular on wagons, buggies and carriages, the semi-elliptical springs were often used on both the front and rear axles. They did, however, tend to allow forward and backward sway and had a high center of gravity. By the time powered vehicles hit the road, other, more efficient springing systems were being developed to smooth out the ride for passengers.

For the most part, this article has focused on the suspensions of mainstream front- and rear-wheel-drive cars — cars that drive on normal roads in normal driving conditions. But what about the suspensions of specialty cars, such as hot rods, racers or extreme off-road vehicles? Although the suspensions of specialty autos obey the same basic principles, they do provide additional benefits unique to the driving conditions they must navigate. What follows is a brief overview of how suspensions are designed for three types of specialty cars — Baja Bugs, Formula One racers and American-style hot rods.

The Volkswagen Beetle, or Bug, was destined to become a favorite among off-road enthusiasts. With a low center of gravity and engine placement over the rear axle, the two-wheel-drive Bug handles off-road conditions as well as some four-wheel-drive vehicles. Of course, the VW Bug isn't ready for off-road conditions with its factory equipment. Most Bugs require some modifications, or conversions, to get them ready for racing in harsh conditions like the deserts of Baja California.

One of the most important modifications takes place in the suspension. The torsion-bar suspension, standard equipment on the front and back of most Bugs between 1936 and 1977, can be raised to make room for heavy-duty, off-road wheels and tires. Longer shock absorbers replace the standard shocks to lift the body higher and to provide for maximum wheel travel. In some cases, Baja Bug converters remove the torsion bars entirely and replace them with multiple coil-over systems , an aftermarket item that combines both the spring and shock absorber in one adjustable unit. The result of these modifications is a vehicle that allows the wheels to travel vertically 20 inches (50 centimeters) or more at each end. Such a car can easily navigate rough terrain and often appears to "skip" over desert washboard like a stone over water.

The Formula One racing car represents the pinnacle of automobile innovation and evolution. Lightweight, composite bodies, powerful V10 engines and advanced aerodynamics have led to faster, safer and more reliable cars.

To elevate driver skill as the key differentiating factor in a race, stringent rules and requirements govern Formula One racecar design. For example, the rules regulating suspension design say that all Formula One racers must be conventionally sprung, but they don't allow computer-controlled, active suspensions. To accommodate this, the cars feature multi-link suspensions , which use a multi-rod mechanism equivalent to a double-wishbone system.

Recall that a double-wishbone design uses two wishbone-shaped control arms to guide each wheel's up-and-down motion. Each arm has three mounting positions — two at the frame and one at the wheel hub — and each joint is hinged to guide the wheel's motion. In all cars, the primary benefit of a double-wishbone suspension is control . The geometry of the arms and the elasticity of the joints give engineers ultimate control over the angle of the wheel and other vehicle dynamics, such as lift, squat and dive.

Unlike road cars, however, the shock absorbers and coil springs of a Formula One racecar don't mount directly to the control arms. Instead, they are oriented along the length of the car and are controlled remotely through a series of push and pull rods. They translate the up-and-down motions of the wheel to the back-and-forth movement of the spring-and-damper apparatus.

The classic American hot rod era lasted from 1945 to about 1965. Like Baja Bugs, classic hot rods required significant modification by their owners. Unlike Bugs, however, which are built on Volkswagen chassis, hot rods were built on a variety of old, often historical, car models: Cars manufactured before 1945 were considered ideal fodder for hot rod transformations because their bodies and frames were often in good shape, while their engines and transmissions needed to be replaced completely. For hot rod enthusiasts, this was exactly what they wanted, for it allowed them to install more reliable and powerful engines, such as the flathead Ford V8 or the Chevrolet V8.

One popular hot rod was known as the T-bucket because it was based on the Ford Model T. The stock Ford suspension on the front of the Model T consisted of a solid I-beam front axle (a dependent suspension), a U-shaped buggy spring (leaf spring) and a wishbone-shaped radius rod with a ball at the rear end that pivoted in a cup attached to the transmission.

Ford's engineers built the Model T to ride high with a large amount of suspension movement, an ideal design for the rough, primitive roads of the 1930s. But after World War II, hot rodders began experimenting with larger Cadillac or Lincoln engines, which meant that the wishbone-shaped radius rod was no longer applicable. Instead, they removed the center ball and bolted the ends of the wishbone to the framerails. This " split wishbone " design lowered the front axle about 1 inch (2.5 centimeters) and improved vehicle handling.

Lowering the axle more than an inch required a brand-new design, which was supplied by a company known as Bell Auto. Throughout the 1940s and 1950s, Bell Auto offered dropped tube axles that lowered the car a full 5 inches (13 centimeters). Tube axles were built from smooth steel tubing and balanced strength with superb aerodynamics. The steel surface also accepted chrome plating better than the forged I-beam axles, so hot rodders often preferred them for their aesthetic qualities, as well.

Some hot rod enthusiasts, however, argued that the tube axle's rigidity and inability to flex compromised how it handled the stresses of driving. To accommodate this, hot rodders introduced the four-bar suspension , using two mounting points on the axle and two on the frame. At each mounting point, aircraft-style rod ends provided plenty of movement at all angles. The result? The four-bar system improved how the suspension worked in all sorts of driving conditions.

For more information on car suspensions and related topics, check out the links below.

Car Suspension FAQ

What does suspension do for a car, what are the parts of a car suspension, how long do car suspensions last, what causes car suspension problems, how do you know if your suspension is damaged, lots more information, related articles.

- How Car Engines Work

- How Car Steering Works

- How Champ Cars Work

- How Differentials Work

- How NASCAR Race Cars Work

More Great Links

- Car Bibles: Complete Guide to Car Suspension

- Monroe Shocks and Struts Tech Support

- Samarins.com: How to check car suspension and steering when buying a used car

- "Bose suspension." Edmunds.com, Inside Line. Accessed April 26, 2005.

- http://www.cars.com/carsapp/national/?szc Cars.com Glossary Double wishbone suspension.

- Clynes, Tom. 2004 Better living through curiosity. Popular Science. December 3.

- DiPietro, John. 2004. http://www.edmunds.com/insideline/do/Features/articleId"

- http://www.edmunds.com/insideline/do/Features/articleId" Encyclopedia Britannica 2005, s.v. "damping." CD-ROM, 2005.

- http://www.edmunds.com/insideline/do/Features/articleId"Kahn, Dan. http://www.monroe.com/tech_support/tec_default.asp http://www.rodandcustommagazine.com/techarticles/135_0312_solid/ Monroe Shocks and Struts. Tech Support, Technical Training.

- Sherman, Don. http://www.automobilemag.com/news/0411_praxis/%0A

- Wright, Michael and Mukul Patel, eds. 2000. Scientific American: How things work today. New York: Crown Publishers.

Please copy/paste the following text to properly cite this HowStuffWorks.com article:

Understanding Your Car Suspension Setup

Do you know how your car's suspension system works?

What is car suspension? It seems like a silly question because you already know that suspension is the bit that connects the wheel to the vehicle. And if you're even more of a car nerd, you'll be able to identify and name all the different components. But vehicle suspension is a topic that creates almost as many arguments as gas vs diesel or a V-engine configuration versus an inline layout . So in this discussion, we'll look at stiff suspension vs soft suspension and which is best; but before we get there, we first need to understand how complex this topic actually is.

Here's an abbreviated version of the history: Man invents the wheel. Or woman invents the wheel. We don't actually know because it predates recorded history. Man then connects two wheels with a log and invents a solid axle. Put a few pieces of wood between the two, and presto - the wagon was born. Then another wagon was built, and racing was born. Only kidding.

In any case, it took a few hundred years for man to realize that connecting the body directly to the axle was a bad idea. Every bump the wooden wheels were subjected to reverberated straight through the entire cart. The first solution for this problem was to use chains to hang the frame from the axles. This only delayed the inevitable knock that would follow, so man came up with leaf springs. Leaf springs predate the American Revolutionary War and are the most basic suspension setup still in existence today, so Fred Flintstone would probably be the only person to see this system as highly advanced.

What is a Car Suspension System?

With the above in mind, the most basic definition of suspension is a series of components connecting the wheel to the car to allow the two entities (wheel and car) to move semi-independently from each other. Basically, a way of alleviating the kinetic energy from any bump or imperfection the wheel may encounter. All of this is related to the most basic function, which is comfort. But the modern car demands a lot more than just that. A modern car's suspension is a complex system, and in most cases, consists of the following components:

- Coil springs, leaf springs, or air-based suspension

- Shock absorbers

- The rods and linkages between the components

- The bushings and joints that connect the various components

Types of Suspension

You could write a book about all of the different types of suspension setups, but we'll break it down into two main categories for this article.

- Non-independent (dependent) suspension: Basically, this is any suspension where the wheels are connected via a single solid axle. What happens to one wheel will affect the other. The best modern example of this is the Jeep Wrangler , which has solid Dana axles front and rear. Jeep still uses this setup because of its inherent toughness and fundamental physics. When the wheel on the right side is pushed up, the wheel on the left is forced down. As you can imagine, this makes for epic articulation, which makes it such a good off-roader.

- Independent suspension: There are various examples of independent suspension, with MacPherson Struts, multi-link, and double wishbones being the most common. The main difference between an independent setup and a non-independent setup is that all four cars' wheels are treated as independent entities. What happens at one corner will not affect the other. Cost is most often the deciding factor when it comes to which of the above a manufacturer uses. MacPherson struts are relatively straightforward and cheap to manufacture. A multi-link setup is any suspension setup with three or more lateral bars (arms) and one lateral bar. Manufacturers can add more than one lateral bar as well. There isn't a single standard setup, which manufacturers tend to design in-house depending on the car's needs.

Different Suspension System Settings

As mentioned earlier, the Jeep Wrangler Rubicon uses solid Dana 44 axles because they're arguably the best, most cost-effective solution for off-road vehicles. The same goes for leaf springs, which you'll find at the rear suspension of most pickup trucks on sale in the USA. At the front, they'll have an independent setup, which is why you'll often hear the term semi-independent suspension.

Suspension settings depend entirely on the purpose of a car. Something as mundane as a Volkswagen Golf will use a McPherson strut at the front because it's cheap to mass manufacture yet adaptable enough to offer both comfort and the necessary grip levels. Even the VW Golf GTI uses this setup at the front and a multi-link setup at the rear. This provides the best of both worlds, as it can be both comfortable and sporty. Thanks to the invention of adaptive damping and air suspension, drivers can now choose how they want the suspension to react, but more on that later.

Most drivers want soft shocks or a soft suspension. This is easy enough to provide these days with independent options like the McPherson strut and double-wishbone suspension. A perfect example of this comfort-first approach is a luxury car like the Lexus ES. The front suspension is a MacPherson strut placed at an angle to provide a smooth ride. At the rear, it has a trailing arm with a high mounting point, which allows for a larger bushing size. All of this means the Lexus glides down the road as syrup runs down a hot pancake.

Higher up in the chain, you have some seriously advanced comfort-biased suspension setups. Manufacturers struggled with air when it first came along, but over the years, this system has been refined to a point where it's now virtually the gold standard in the luxury barge segment.

For a prime example, look no further than the all-new 2022 Mercedes-Benz S-Class . As standard, it has an air suspension system and active suspension dampers. The former is simply there to carry the body's load, while the latter is connected to a 48-volt system that can change the damping rate at all four wheels. Let's say the new rear-wheel-drive S-Class is accelerating from a standing start. Usually, the car's nose will lift slightly, while the rear hunkers down - because physics. The new S-Class can counteract this by balancing the forces at both axles. We were never bothered by the physical reaction of acceleration, as it was simply a given - like the sun coming up every morning. But along comes Merc and removes it via an intelligent suspension setup. There's also a new E-Active Body Control suspension setup that uses a camera and multiple sensors to scan the road ahead. It does this more than 1,000 times per second. Depending on the mode, it will prep the suspension for what's coming. If it detects a bump on the right side, it will prime the suspension to soak it up perfectly. In a more dynamic mode, it can firm up the right wheels for a tight left corner. Heck, it can even give the rear left wheel a bit more articulation when it starts spinning.

Stiff vs Soft Suspension: The Best Setup for Comfort and Performance

If you're wondering what suspension is better for comfort and which is better for performance, the answer is the same. A car has four independent wheels, which travel at different speeds, and are subject to various forces. That's why an independent suspension is the best for everything, including off-roading. We can hear the solid car axle and leaf spring fans moaning in the back, but for proof, look no further than the Land Rover Defender. It has a fully independent multi-link air suspension. Not only does it make it refined on the road, but the air suspension allows for impressive articulation. At the same time, the multi-link setup has greater control over lateral and longitudinal movements. Essentially, it improves grip, which is the essence of off-roading.

As we learned above from the new S-Class and Lexus ES, independent is also the perfect solution for a comfort suspension. Coupled with adaptive damping, it can also offer the best balance between comfort and performance. Take any of the current super-sedan cars out there: Mercedes-AMG E 63 S, Audi RS6 Avant, and BMW M5. All of them have adaptive damping, which allows them to be reasonably comfortable and ridiculously stiff when the mood for driving fast strikes.

For sports cars , independent also works best. A multi-link setup allows for great lateral and longitudinal control, improving grip. But the positives are not just limited to the lateral arms providing more grip. An adjustable shock absorber can be tuned to provide an effective damping rate, while a positive caster setting (the axis of the shock absorber) can increase grip. On performance SUVs, the norm is an air suspension, which allows for comfortable damping daily, but the car can also be lowered by a few inches to decrease the center of gravity.

How to Improve a Suspension Setup

If you're a casual car enthusiast who doesn't participate in track days, best stick with the standard OEM suspension. A manufacturer spent millions of dollars finding the perfect balance for your car, so best keep it that way. Since an independent suspension is such an intricate system, you can easily mess up the whole system by changing one component. A strut brace is a perfect example. It's affordable and easy enough to install, but your car's multi-link suspension's movement may be limited and damaged by the increased rigidity. A suspension swap is easy enough on a pickup with leaf springs. There are various manufacturers out there that offer adjustable shock absorbers that improve ride quality.

With the above in mind, here are some changes you can make to (hopefully) increase performance. We'll also include some pros and cons.