Calibration & Thermographic Inspections Service

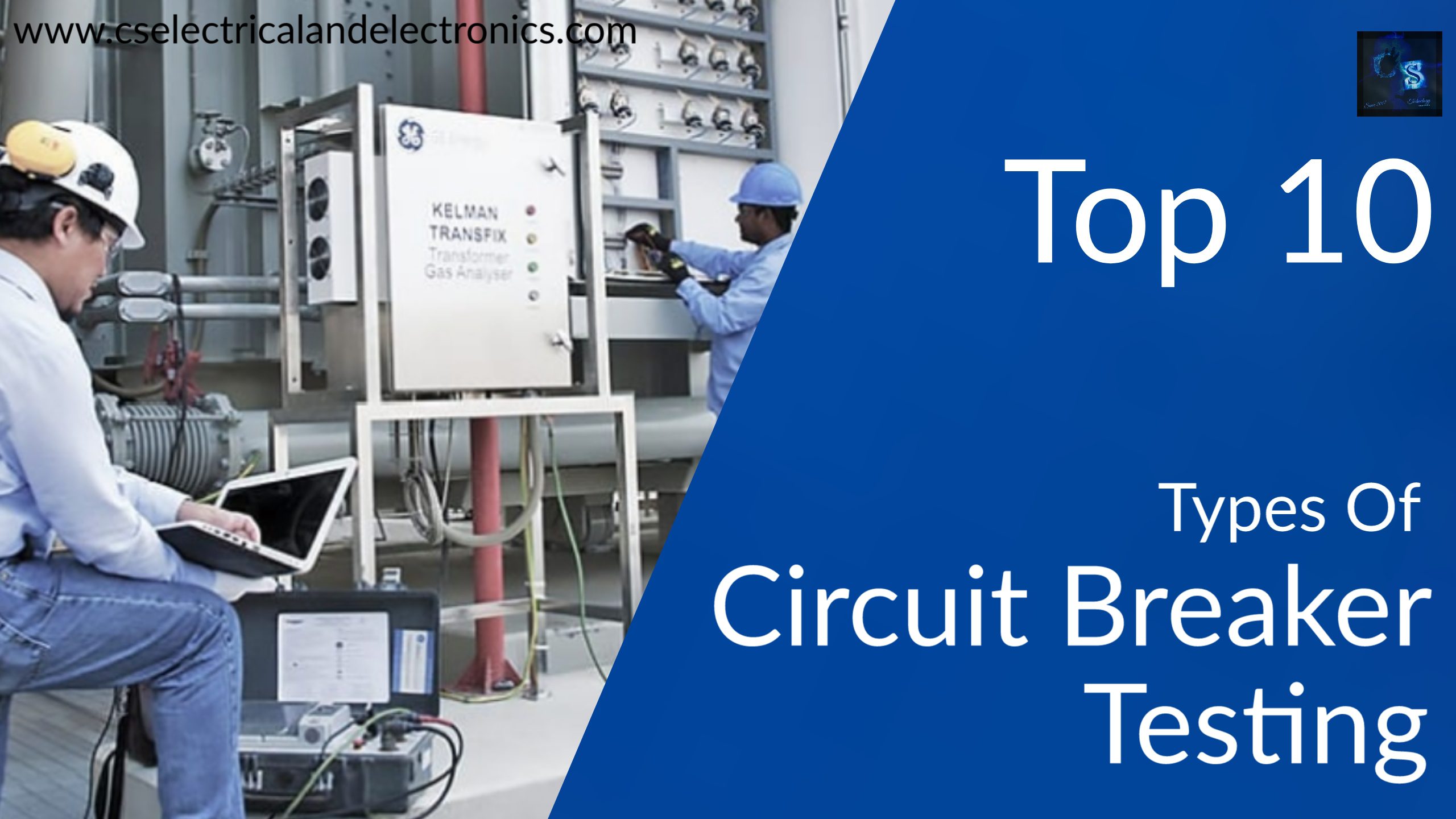

What is circuit breaker testing and how is it done.

Circuit Breaker Testing is utilised to test the operation of each switching systems and the programming of the entire tripping structure. Circuit Breaker Testing is essential to ensure the safe and reliable performance of this key link in the power asset chain. Circuit breakers perform three main tasks :

- They should conduct the current as efficiently as achievable, when closed.

- When open, they must insulate the contacts from one another as effectively as possible.

- In the event of a malfunction, they must disconnect the fault current as quickly and reliably as possible, thereby protecting all subsequent equipment.

Performing circuit breaker testing is more challenging with comparison to other electrical components like transformer as the short circuit current is greater. In the US market and regions of frequent earthquakes, the most popular high-voltage circuit breakers are “dead tank” units, whereas in central Europe “live tank” breakers are standard. Elsewhere both circuit breaker types are obtainable.

Why is Testing Circuit Breaker Important ?

A circuit breaker might stay idle years, but if a malfunction occurs it has to detach fault currents of huge kiloamps gradually within a few milliseconds. Major errors that happen on circuit breakers are incorrect behavior, short circuits in the coils, damage/wear to the mechanical connections or the insulation material. Therefore, circuit breakers need to be regularly and carefully tested. Circuit breakers perform a vital role in protecting expensive equipment from damage through faults i.e. connecting and disconnecting the electrical power in a reliable way; this requires proving their reliability with on field tests during installation and with regular maintenance tests during its lifetime to prevent costly failures and problems that could even compromising the safety of the substation. Testing the performance of your circuit breakers regularly is therefore an essential and cost-effective part of any maintenance strategy. Circuit breaker testing particularly concentrates on obtaining motion and time values on the units. However, our testing solutions have revolutionized circuit breaker testing. Performing the tests without use of the station battery greatly increases safety throughout the testing process.

What are the Steps in Circuit Breaker Testing?

Type tests of circuit breaker.

Type tests are organised with the aim of proving the abilities and making sure the rated characteristic of the circuit breaker are exact. Such tests are conducted in the specially built testing laboratory.

- Mechanical Test – It is mechanical ability type test involving the repeated opening and closing of the breaker. A circuit breaker must close and open at proper speed and do its allocated job and function without any failure.

- Thermal Test – Thermal tests are carried out to check the thermal behavior of the circuit breakers. Due to the streaming of rated current through its pole in a rated condition, the breaker under test undergoes steady-state temperature rises. The temperature rise for rated current should not exceed 40° for current less than 800A normal current and 50° for normal value of current 800A and above.

- Dielectric Test – These tests are performed to check power frequency and impulse voltage withstand capacity. Power frequency tests are kept on a new circuit breaker; the test voltage changes with a circuit breaker rated voltage. In impulse tests, impulse voltage of particular value is employed to the breaker. For outdoor circuit dry and wet tests are conducted.

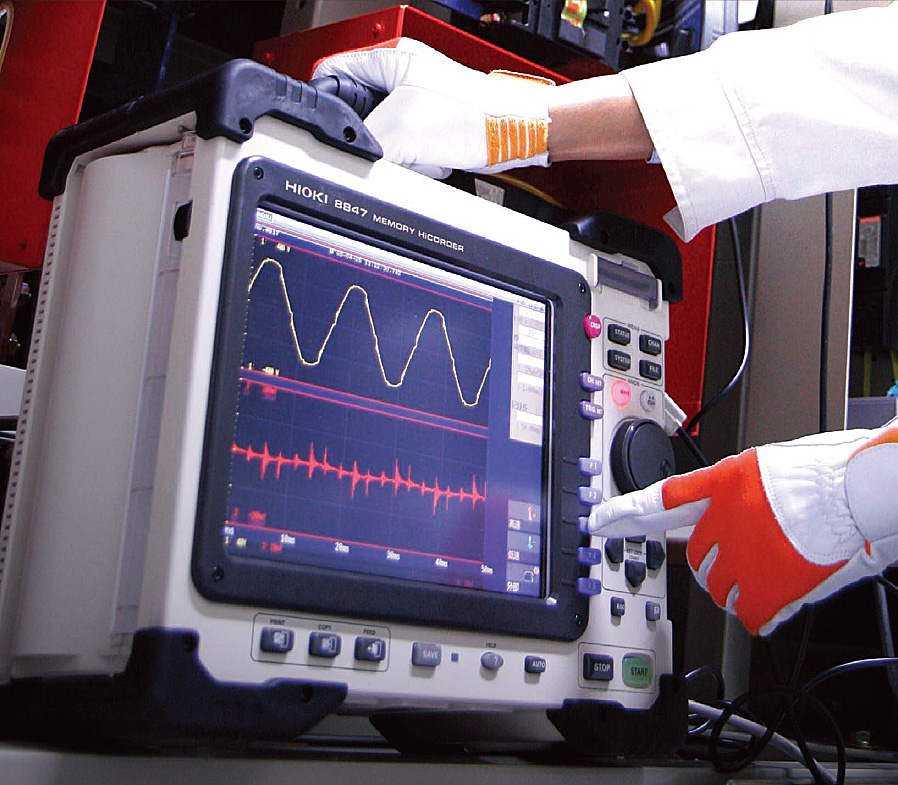

- Short -Circuit Test – Circuit breakers are subjected to sudden short-circuits in short-circuit test laboratories, and oscillograms are taken to know the behaviour of the circuit breakers at the time of switching in, during contact breaking and after the arc extinction. The oscillograms are studied with particular reference to the making and breaking currents, both symmetrical and asymmetrical restriking voltages, and switchgear is sometimes tested at rated conditions.

Routine Tests of a Circuit Breaker

Routine tests are done as per references of standards of Indian Engineering Service and Indian Standards. These tests are performed on the manufacturers’ premises. Routine tests confirm the proper functioning of the circuit breaker. The routine tests confirm the proper functioning of the circuit breaker. Routine testing doesn’t necessarily include complex gear in order to ensure that a circuit breaker is functional. Some guidelines and recommendations for these tests include routine maintenance and verifying that that circuit breaker performance is in line with manufacture’s calibration curves. It is crucial that these tests are performed under stable conditions at suitable temperature so that there are no variations in the data. Some of the tests are listed below.

Preventative Maintenance of Circuit Breaker, Inspection, and Testing

Preventative maintenance depend operating conditions for circuit breakers. Primary inspections of CB (circuit breakers) will look at particulate matter that’s contaminating the inner workings of the CB. Accumulation of particulates can generally be disposed of by flipping the lathe on the breaker “Off” and “On” switch to clear away the accumulated dust

Circuit Breaker Trip Test

By analysing the current consumed by the trip coil during the circuit breaker’s operation, it is possible to determine whether there are mechanical or electrical issues present. In many cases, such issues can be localised to aid in finding the root cause. Optionally, monitoring the tripping supply’s voltage during the operation can detect issues arising with tripping batteries.

Insulation Resistance Test

For individual breaker resistance testing, load and line conductors should be preferably disconnected. If not detached the test values will also involve the characteristics of the connected circuit. Resistance testing is crucial for verifying that the insulating material which makes up the molded cases breakers are performing correctly. In order to test for insulation resistance, an instrument known as a megger is used. A megger instrument applies a known DC voltage to a given wire for a given period of time in order to test the resistance within the insulation on that particular wire or winding. It is vital that voltage is employed as the resistance checked with an ohmmeter may differ when there are no report of potential differences. It should also be noted that if you apply a voltage that is too high for that insulation to withstand, then you could potentially damage the insulation.

Connection Tests

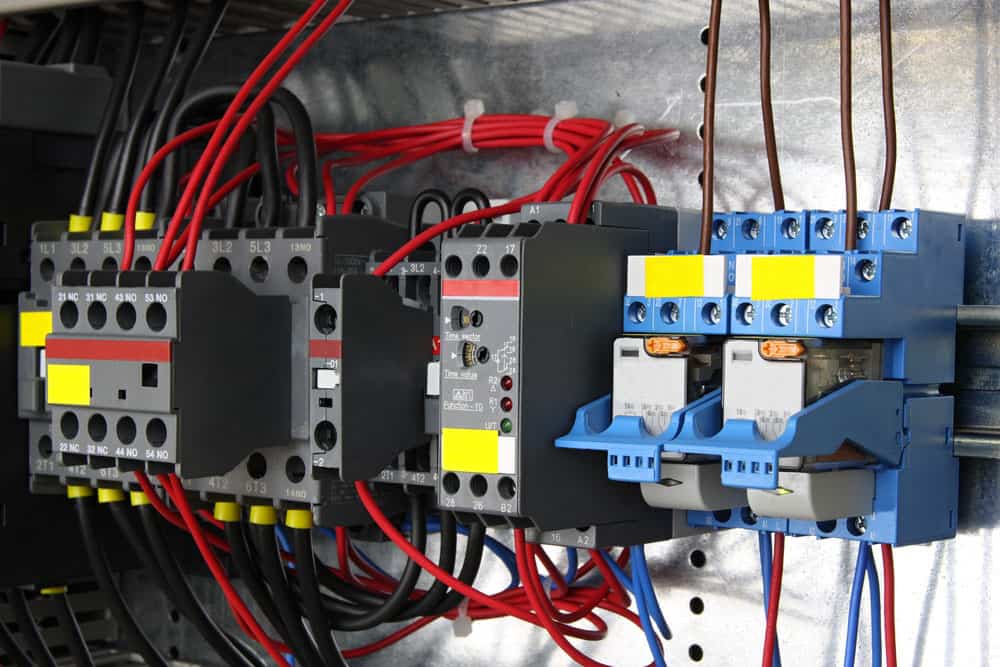

Connection testing is important to make sure that an appropriate electrical connection is available and to recognise traces of overheating denoted by colour difference. It is important that electrical connections are properly installed to the CB to prevent and reduce overheating.

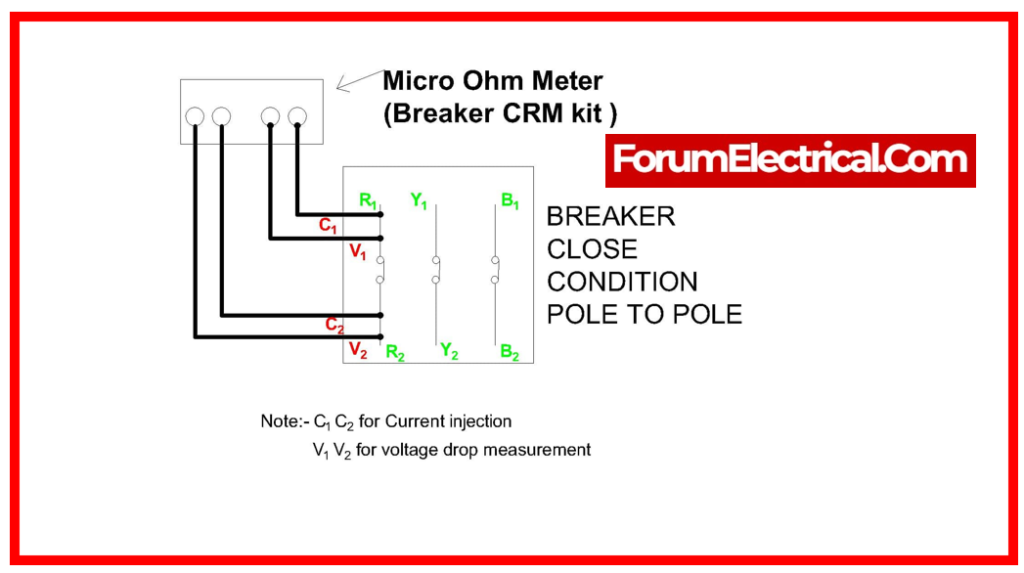

Contact Resistance Test

Normal wear and tear of contacts within the CB emerges after extended usage. An easy method to identify traces of weakening within the circuit breaker is to quantify the resistance across every pole of the breaker. Indications of abnormal conditions within the CB such as erosion and contamination of contacts are evident if there are excessive millivolt drops across the breaker. The contact resistance test is important in finding out if or not a circuit breaker is still apt for functioning.

Overload Tripping Test

Overload tripping components of CBs can be tested by inputting 300% of the breaker rating into each pole of the circuit breaker to determine that it will open automatically. The motive of this is to make sure that the circuit breaker will operate or not. Refer to NETA standards for trip times that are acceptable for the overload tripping test. When trying to find out tripping characteristics, it is advisable to consult with manufacturer’s manuals.

Instantaneous Magnetic Tripping

In routine tests, it is relevant to find out that the magnetic feature is functional and will trip the circuit breaker instead of finding the precise value at which the instantaneous magnetic feature functions.

How Testing of Circuit Breaker is Performed?

Different circuit breaker test equipment are used to check the operation and condition of circuit breakers on the power systems. How to test a circuit breaker involves many different test techniques and type of testers. This will define how to test a circuit breaker through different testing tools to be applied to check the equipment under a range of conditions or operation types. Discover how to test a circuit breaker with the different test sets that you can need.

Testing with Different Equipment:

To consider how to test a circuit breaker, it is required a deep knowledge of the breaker itself:

- How it works

- Its tolerances,

- Reference values of previous tests,

- Initial values with which to compare the actual results, sometimes defined by a rated timing graph,

- Established settings or initial features given by manufacturer

In this sense, how to test a circuit breaker becomes a trending analysis since test results are not always definitive but have meaning just when compared to previous data or results.

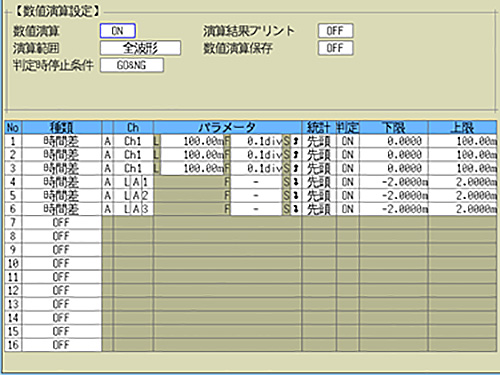

Testing with Circuit Breaker Analyzer

The timing tests of the different open and close operations of the breaker is an efficient way of how to test a circuit breaker, analyzing not only the trip times but also the essential synchronism of the poles in the different operations. This define how to test a circuit breaker through different simulations of its operation, which can be directly commanded from the circuit breaker analyzer, or initiated by an external signal, checking the opening or closing time of each pole, in single or combined operations, and checking the possible difference between poles or mismatch time which may lead to a dangerous lack of synchronism. How to test a circuit breaker with a circuit breaker analyzer depends also on the type of possible problems to be confirmed, which leads to check other features such as the possible bouncing, the proper performance of the pre-insertion resistances, the coils condition, and the mechanical analysis through contact travel speed and acceleration data with the use of the appropriate transducers.

Testing with a Micro-ohmmeter

Circuit breakers generally bear a huge value of current. Greater contact resistance cause greater losses, low current carrying capability and threatening hot spots in the breaker, so that the resistance testing with micro-ohmmeters are other way of how to test a circuit breaker for identifying and avoiding upcoming issues. How to test a circuit breaker with a micro-ohmmeter requires also reliable measurements and a wide injection range with high power that enables for longer test leads, less connections problems, and more accurate measurements.

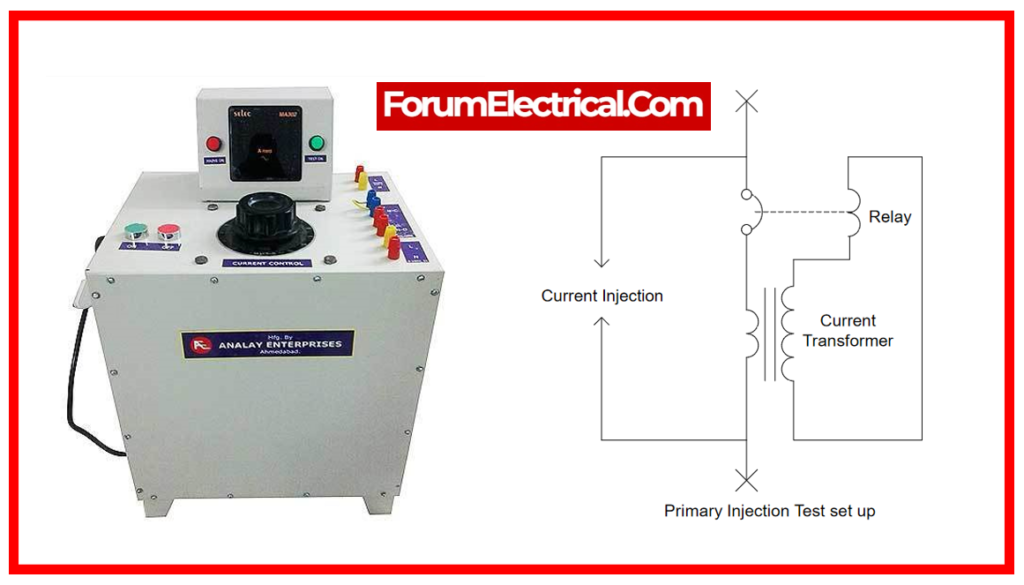

Testing with a High Current Primary Injection Tester

The analysis of the tripping time characteristics of LV circuit breakers and molded-case circuit breakers is performed using high current injection, as the way to check the entire functionality. How to test a circuit breaker of this type depends on its maximum rated current, the trip protection settings and the inverse curve types which will define the overload and short-circuit trip pickup levels and time delays; all these features must be checked with the appropriate primary injection test set with the capacity to simulate the corresponding high current faults required and capture the answer of the breaker. A system which be easily upgraded in power capacity enables how to test a circuit breaker in the different possible situations and range of breakers; how to test a circuit breaker of this kind also needs a bendable design of the test set to fruitfully attain the certain large current job, and a design that create possible to position it nearer to the breaker, and so decreasing the power needed with smaller test leads; this is the case of the Raptor System, a modular and flexible primary injection system which easily and quickly adapts its power capacity to the several high currents ratings of the different circuit breakers.

Benefits of Circuit Breaker Testing

- Quick and easy to perform on site

- Circuits can be tested on or off load

- Tests performance of whole tripping cycle

- Tests overall timing of tripping system

- Identifies need for maintenance

- Part of a comprehensive diagnostic maintenance program

- Find early indications of possible problems

- Avoid issues other than pick up pieces

- Build up a test record database for trending

- Pick out the bad actors

- DUTY OF CARE

- Electrical Low Voltage Testing

- Temperature & Humidity Calibration

- Electrical Inspection

- Electrical Study & Analysis

THE BEGINNER’S GUIDE TO FIRE SPRINKLER TESTING & PREVENTION

If you have a fire sprinkler system, you don’t actually need to test it , right? Wrong. Sure, testing is performed to comply with NFPA regulations , insurance requirements, and to keep you out of trouble with the fire department (ahem, violations ). But it also lets you know if your system is working properly.

The types of tests that can be performed depend on the type of system you have. Different tests are performed to check your system’s functionality, as well as all the specific components of your system. In this post, we’re going to review:

- 2” Main Drain Test

- Water Flow Alarm Device Test

- Fire Pump Test

- Dry Pipe Valve Trip Test

- Hydrostatic 5 Year Functionality Test

Do you need help testing your fire sprinkler system? Get a free estimate today!

2” MAIN DRAIN TEST

The main drain test is required by NFPA25 to be performed annually to ensure the proper water supply is available at the system riser, detect changes in the water supply that may affect the sprinkler system’s performance, and confirm the drain valves are operational.

If the measurement between the inspections varies more than 10%, that could be a sign of a problem like a large obstruction, a dropped gate, a valve that is almost fully closed, or a check valve clapper stuck to the valve seat.

How to perform the main drain test:

- Record the pressure shown on the gauge. This is known as static pressure.

- Locate the main drain valve and turn slowly to turn the water on. Allow the water to run until pressure stabilizes.

- Record the pressure shown on the gauge. This is known as residual pressure.

- Close the main drain by turning it slowly.

*Tip: During the test, water is piped outside or into a drain. It is best to avoid performing the test during the winter when the water outside can turn to ice, leading to an injury.

WATER FLOW TEST

The water flow test is required by NFPA25 to be performed quarterly to ensure water flow detecting devices are operational, alarms are operational, and a signal is sent to and received by the central station (if connected).

It is important to inform the fire department and/or central station before you perform the test. Depending on what type of alarm device your system has, either a water motor gong sounds the alarm or an electrical water flow switch is tripped when water is flowing through the pipe.

How to perform the water flow test:

- If connected to a central alarm, notify the fire department and/or central station about the test.

- Locate the inspector’s test valve and slowly open so that the valve is in line with the pipe.

- Allow the water to flow for about 60 seconds or until the alarm sounds. If connected to central station, call to confirm the signal was received.

- Slowly close the inspector’s test valve. Notify the fire department and/or central station that test is complete.

FIRE PUMP TEST

The fire pump flow test is required by NFPA25 to be performed annually and measures the performance of the fire pump’s flow and pressure. The test is conducted by flowing water through hose streams connected to the test header. The test results are compared to the factory specifications and the test results from previous years. If there is a significant reduction in the pump’s performance, further examination is needed to make the necessary repairs.

The 2011 Edition of NFPA 25 requires electric motor driven fire pumps to be operated monthly. This is known as a churn test.

For more information, check out our blog post on the requirements for fire pump testing .

DRY PIPE VALVE TRIP TEST

Partial Trip Test

The partial dry pipe valve trip test (say that 3 times fast) is required by NFPA25 to be performed annually. During the test, the control valve is only partially opened so that no water is released. The system must trip in under 60 seconds. After the test is completed, the low points are drained and the valve is reset.

Full Trip Test

A full flow trip test is required by NFPA25 to be performed every 3 years. During the test, the control valve is opened completely to allow the flow of water. The system must trip in under 60 seconds. After the test is completed, the low points are drained and the valve is reset. After the test is completed, the low points are drained and the valve is reset.

*Tip: Dry pipe valves should be trip-tested during warmer weather to avoid freezing.

HYDROSTATIC 5 YEAR TEST

The hydrostatic test is a Fire Department requirement, it is not required as part of your annual NFPA25 inspection contract. The 5 year hydrostatic test, also known as a functionality test, confirms the fire sprinkler/standpipe components are in working condition and are acceptable for fire department use.

The test is completed by applying hydrostatic pressure to the fire department connection and maintaining the pressure for up to 2 hours. It must be conducted by a licensed fire sprinkler contractor, such as Capitol Fire Sprinkler in the presence of the Fire Department.

To learn more about the hydrostatic test, check out our post: Everything You Need To Know About the Hydrostatic Test and 4 Reasons to Schedule a Pre-Test for Your 5 Year Hydrostatic Test .

- Inspections

- Installation

- Maintenance

Recent Posts

CALL (718) 533-6800 FOR A FREE ESTIMATE!

- Basic Electrical

- Electrical Laws

- Electrical Tools

- Electrical Formulas & Equations

- Electrical Calculators

- Preventive Maintenance

- Electrical Procedures

- Electrical Projects

- Electrical Notes & Articles

- Electrical How to

- Troubleshooting

- Electrical Symbols

- Excel Tools

- Transformers

- Electric Motors

- Generations

- Transmission

- Distribution

- Measurement

- Control Systems

- Electrical Safety

- Electrical Interview

- Electrical MCQ

- Instrumentation & Control

- Renewable Energy

- Electrical Vehicles

- Submit Articles

- Freelance Job

- Privacy Policy

- Power Systems

12 Fundamental Testing of High Voltage Circuit Breaker

Introduction

Types of circuit breakers, conventional testing procedures, 1). first trip test, 2). primary injection test, 3). contact resistance measurement, 4). dynamic resistance measurement (drm), 5). main circuit dielectric test, 6). main circuit resistance test, 7). auxiliary & control circuit tests, 8). tightness test, 9). o-c timing test, 10). coil resistance test, 11). travel test, 12). aesthetic test.

Circuit breakers may not be the most noticeable types of equipment in a substation.

They spend a significant amount of time doing nothing except waiting in expectation.

However, there will come a time when the circuit breaker must operate properly and promptly.

Unfortunately, all electrically controlled devices will eventually malfunction, and if a circuit breaker fails to function properly, problems can cascade with potentially disastrous consequences.

However, testing allows technicians & substation managers to alleviate their concerns regarding circuit breaker functionality.

Circuit breakers protect equipment that is an essential component of the infrastructure and expensive to replace; keeping the breakers in good working order minimizes outages, which saves utilities & their customer’s time and money.

Furthermore, there is a genuine public service component to providing a consistent supply of power, avoiding corporate downtime and customer “dark” time. Substation breaker testing is a significant responsibility for all electricity companies.

The proper operation of a breaker is dependent on several distinct components that need to be calibrated & tested on a regular basis.

The parameters used to establish maintenance intervals vary widely amongst power utilities, although they frequently include time since the last test, number of operations, and the extent of fault current activities.

Environmental factors like as humidity and temperature – either the breaker is situated in a desert (or) coastal region – also influence the repair timetable.

International standards define the design and functioning of high voltage circuit breakers, as well as their type and routine tests.

IEC 62271-SER ed1.0 – High-voltage switchgear & control gear.

ANSI/IEEE C37 – Guides & Standards for Circuit Breakers, Relays, Switchgear, Substations, and Fuses.

IEC/TR 62063 ed1.0 (1999–2008) TC/SC 17A – High-voltage switchgear & control gear – Application of electronic and related technologies to switchgear and control gear auxiliary equipment.

Circuit breakers can be classed in a wide range of ways, including voltage, application, insulating medium, etc.

Depending on where a circuit breaker is located in the power network, it will require varying levels of reliability.

These standards usually determine the breaker’s testing schedule and the quantity of maintenance it will obtain.

The various types of high voltage circuit breakers comprise the following:

- Oil Circuit Breaker

- Air Circuit Breaker

- Vacuum Circuit Breaker

- SF6 Circuit Breaker

A circuit breaker’s primary functions include opening the circuit in reaction to faults and connecting/disconnecting objects & parts of the electrical network.

Normal-load operations account for the vast majority of circuit breaker switching operations.

Initially, a circuit breaker may appear to have nothing to test, but a closer look shows an advanced system that must function flawlessly in milliseconds.

One of the most important purposes of circuit breaker testing is to measure those milliseconds, also known as main contact timing.

Furthermore, contact movement is nearly always measured as part of the circuit breaker maintenance and service schedule.

In this post, we will look at the most prevalent test methods for breakers as well as some new techniques that are quickly acquiring widespread acceptance.

A circuit breaker’s initial open operation after a long idle period is a good indicator of its condition.

This test involves connecting and measuring the circuit breaker while it is in service.

No test connections are established outside the control cabinet.

The main benefit of a first trip test is to test circuit breaker functioning in “real world” circumstances.

First trip testing will show if the circuit breaker has slowed due to rust or dried grease in mechanism linkages (or) coil armatures.

Traditional alternative test techniques require the circuit breaker to be removed from operation and operated at least one time.

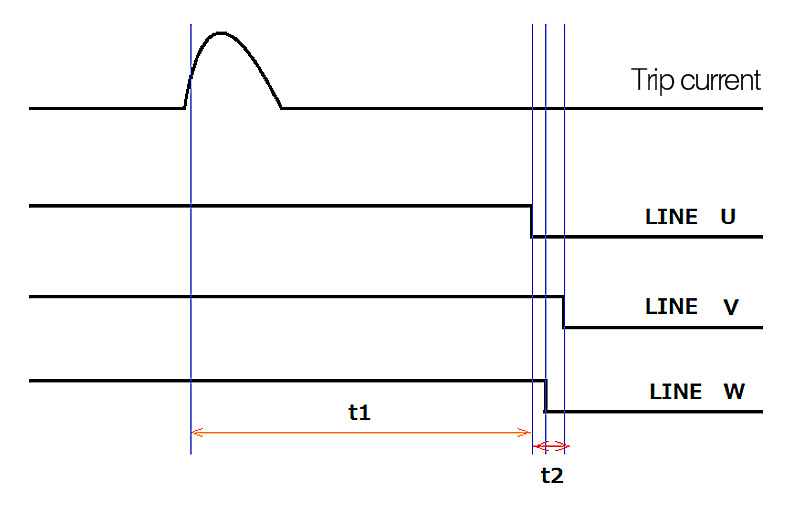

A first trip test on a gang-operated circuit breaker measures one-coil current.

However, an independent pole-operated breaker measures three coil currents. Analysis of coil current signatures reveals circuit breaker state. We can also measure auxiliary contact timing.

The secondary current in the protective CTs can be monitored to determine the circuit breaker’s opening time, but the arcing time is included.

Since parallel primary current paths limit arcing, opening time can be more accurately estimated.

First trip analysis can indicate the following problems:

Main Contact Timing

Main contact timing follows IEC definitions:

- The opening time is the time between activating the trip coil and the arcing contacts separating at all poles.

- The closing time is the period from activation of the closing device (such as the coil) until the moment the arcing contacts touch in all poles.

The primary contact timing test ensures circuit breaker manufacturer-specified opening and closing times.

Timing outside manufacturer guidelines, especially when switching short-circuit currents, increases arcing time. This causes severe contact wear and equipment emergencies such contact melting.

If contacts melt, the breaker must be repaired or replaced.

Correct synchronization between phases and, if there are many breaks / phases, across contacts in the same phase is essential, as are circuit breaker opening and closing times.

Multiple contacts in sequence require phase synchronization. When a breaker opens a circuit, it divides voltage. Too great a time gap between contact operations will cause high voltage across one, causing flashover and perhaps damaging the breaking chamber.

A 3-phase system power transmission system at 50 Hz has a higher tolerance for phase simultaneity as there is typically 3.33 ms across zero crossovers.

However, in such systems, time tolerance is frequently less than 2 ms. In both cases, synchronized switching breakers must meet stricter requirements.

IEC 62271-100 specifies circuit breaker synchronization to be better than 1/4 cycle for shutting and 1/6 cycle for opening. Better than 1/8 cycle synchronization across interrupters in the same phase.

Resistor Contact Timing

Resistor contacts may be pre- or post-insertion. Timing of resistor contacts is done simultaneously with main contacts, but only when main contacts are open can they be detected. Resistance is a good evaluating measure.

Auxiliary Contact Timing

The time connections between primary and auxiliary contacts are not limited, but understanding and checking auxiliary contact operation is essential. Auxiliary contacts close and open circuits.

To prevent coil burnout, such a contact could enable a closing coil whenever a breaker is ready to close and open the circuit shortly after. Relay protection and signalling use auxiliary contacts.

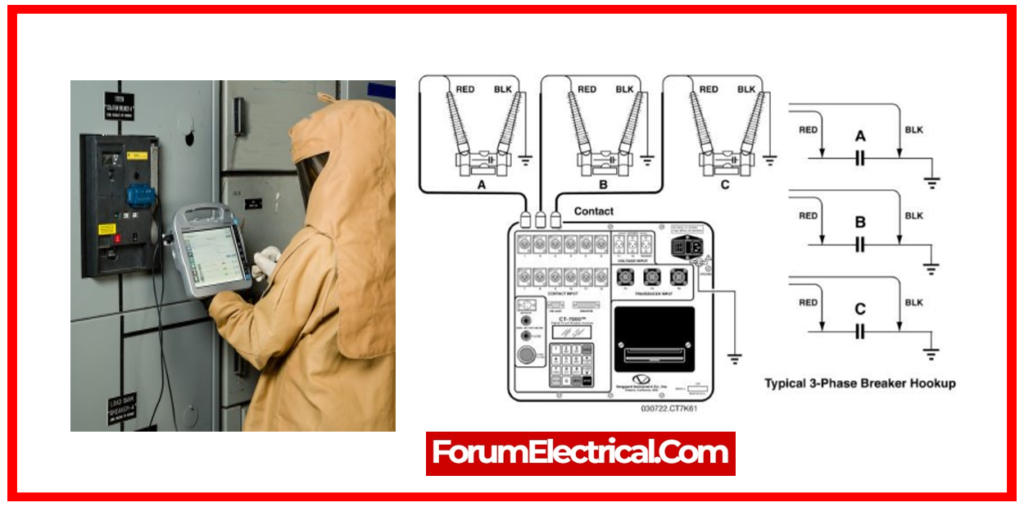

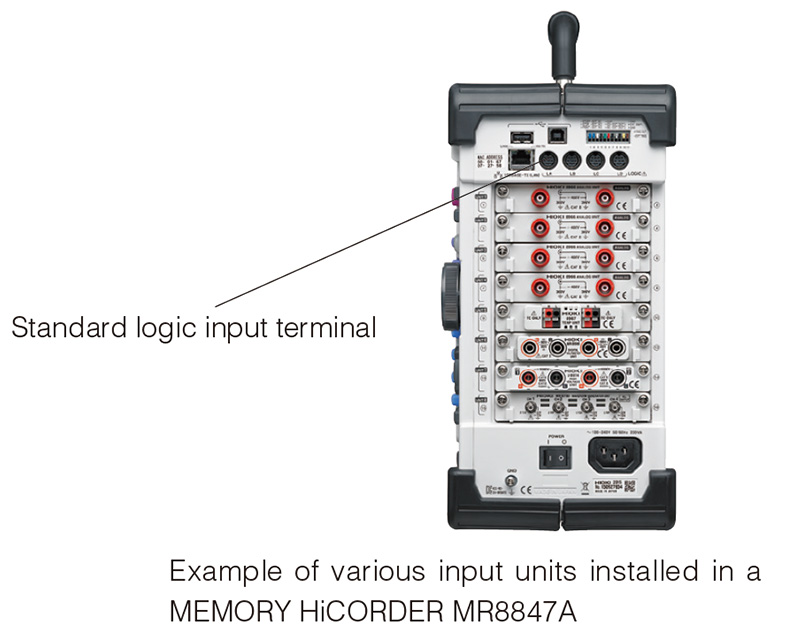

For primary injection testing, a large current is injected into the primary side of the transformer.

The test covers the full chain, which includes the

- Current transformer,

- Wires,

- Connection points,

- Relay protection, and

- Circuit breakers (in some cases).

During primary injection testing, the system undergoing test must be shut down.

This type of test is normally carried out as part of commissioning process.

The only method to ensure that a direct low voltage circuit breaker works properly is to run a strong current through it and observe/record the results.

Main Contact Motion

A high-voltage breaker is intended to stop short-circuit currents in regulated manner.

This places considerable pressure on the mechanical functionality of the operating mechanism & all of the components in the interrupter chamber.

The breaker must operate at a specific speed in order to provide enough pressure for the cooling stream of air, oil, or gas (depending on the kind of breaker) to extinguish the arc formed after contact separation till the next zero crossing.

It is essential to cut off the current to avoid a restrike. This is accomplished by making sure the contacts are adequately separated prior to the moving contact reaching the so-called damping zone.

The arcing zone is the distance required to extinguish the breaker’s electric arc. From the motion curve, velocity & acceleration curves may be derived, revealing even minor changes in the breaker mechanics.

The contact motion is collected by connecting a travel transducer to the moving element of the working mechanism. The transducer generates an analogue voltage in response to the movement of the contact.

Motion is typically represented as a time vs distance curve.

When the circuit breaker is closed, a known DC current is injected via the main contact system to determine contact resistance.

By monitoring the voltage drop, the resistance may be estimated. The value of main contact resistance represents the state of the conducting components. This test is often referred to as static resistance measurement (SRM).

The static resistance value serves as a reference value for all electrical connections and joints. According to IEC56 , this resistance should be measured with a current ranging from 50 A to the breaker’s nominal current.

ANSI C37.09 requires a minimal test current of 100 A.

Many international & national standards establish comparable guidelines to prevent the danger of receiving incorrectly high values if the test current is excessively low.

Heat created by a high test current can disperse contact grease residues or other contaminants found on contact surfaces.

When the circuit breaker contacts are in bad condition, the results can differ significantly from those recorded at the factory while the breaker was new.

ANSI specifies a 200% increase in resistance over the highest value specified by the factory.

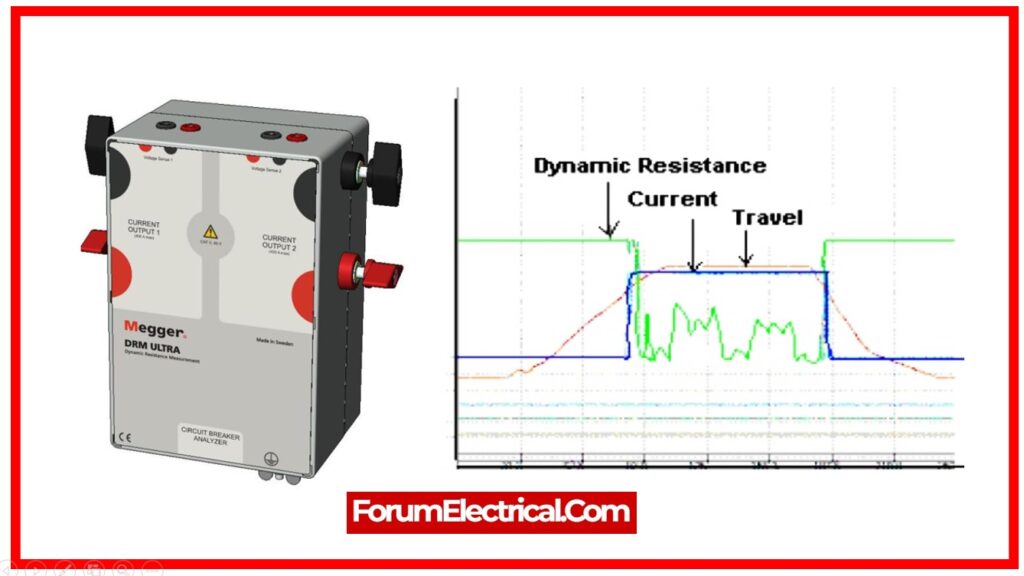

This test is performed by injecting DC current via the breaker’s main contacts and monitoring both the voltage drop & current when the breaker is operational.

These values are subsequently utilized to depict resistance versus time. If contact movement is captured at the same time, the resistance of each contact position can be calculated.

This method is mostly used for contact diagnostics, while it can also be utilized for main contact timing. The only way to determine the total length of arcing contact is to disassemble the circuit breaker.

In SF6 breakers, the arcing contact is often constructed of tungsten. This contact gets burned off & gets shorter with each interruption of the load current. The arcing contact’s shortening is plainly seen from dynamic resistance tests.

To obtain valid DRM data, large test current and test equipment with adequate voltage measurement resolution are necessary.

Electrical Tester, will cover further widely used circuit breaker tests such as coil and voltage tests; vacuum bottle, SF6 leakage, & air pressure tests; & new test methods, like as resonant frequency techniques, which are rapidly gaining popularity.

This test, also known as the ‘Dielectric Withstand Test’, is designed to assess the CB’s withstand capacity against a variety of power frequencies & impulse voltages.

As standard procedure, a dry, high-power frequency voltage test must be performed for 60 seconds. According to the IEC 60061-2 standard, the voltage delivered should be 1.5 – 1.8 times higher than the CB’s rated voltage in a frequency range of 45 to 65 Hz.

Alternatively, unless otherwise indicated by the relevant technical committee, the ideal test voltage levels should be sustained within ±1% of the required level during the test.

For tests lasting more than 60 seconds, maintain voltage readings within ±3% of the required level.

The IEC 62271-100 standard requires a minimum current of 50 amps across the CB. The DC millivolt drop across it should be measured to determine the main contact resistance value using the Kelvins 4-Wire concept.

The main contact resistance value cannot go above 150 micro ohms.

Auxiliary & control circuits are usually tested using three distinct tests:

- Inspection & verification to establish whether the auxiliary & control circuits comply with the specified Circuit and Wiring Diagrams.

- Functional testing of all (LV) low-voltage circuits to check if auxiliary & control Circuits are functioning seamlessly with the other elements of the switchgear and control gear,

- Visual inspection to see if the auxiliary & control circuits may be securely accessed without also risking an electric shock from direct contact with the main circuit.

Manual testing should be performed to determine the tightness of CB’s connections.

Depending on the kind of switchgear, the following three tightness checks should be performed:

- Controlled & closed-pressure tests for the gas-insulated switchgear.

- Sealed-pressure tests for gas-insulated & vacuum-insulated switchgear.

- Perform a liquid tightness test to find any leaks.

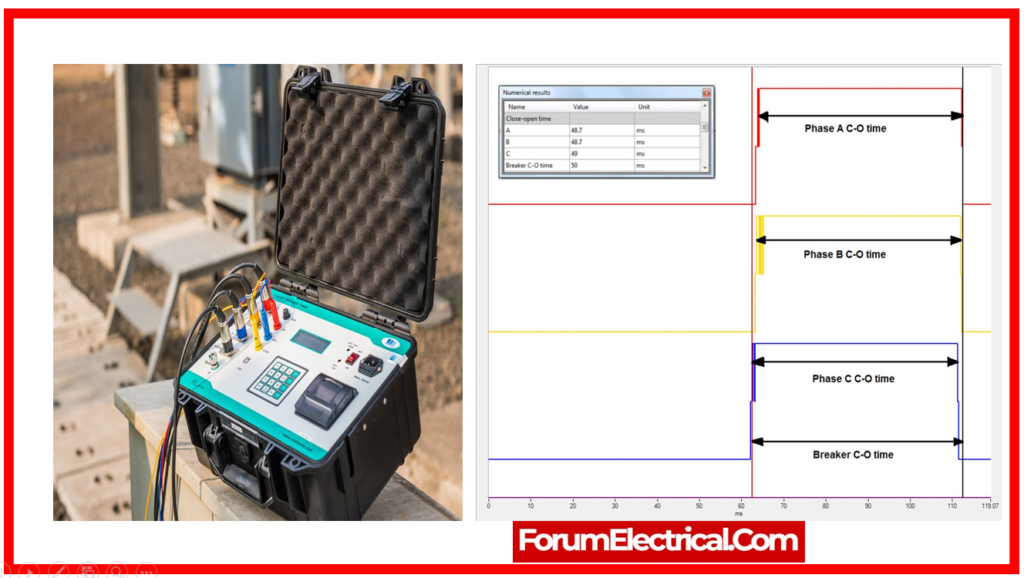

When it comes to avoiding an electrical accident, the opening & closing time of CB are important.

In case of an electrical fault, the CB must quickly open and trip the current, then close when the issue is resolved.

Industry best practices indicate that HV CBs open (& trip) between 30 to 50 ms of fault happening and shut between 60 to 80 milliseconds of the fault being fixed.

However, if the fault persists even after CB has closed, it should reopen, re-trip the current, and then close again. Unpredictable conditions like these make testing the CB’s Opening-Closing (O-C) timings essential.

CBs have dedicated coils for the opening and shutting. Depending on the condition, the relay delivers a ‘coil current’ that activates and operates the relevant coil.

To make sure whether a CB continues to function properly, measuring the resistance levels of each coil is essential.

Every CB’s interrupter has two mechanisms:

- Fixed and

- Movable.

As a CB closes, the moving part moves towards the fixed component, completing the loop.

To make sure that both of these components function properly, travel tests are conducted to assess their effectiveness. There are four basic characteristics to consider while performing trip tests:

Stroke Length: The contacts’ total travel distance from where they are at rest in a given state. For example, in a closed state, the distance travelled from resting posture to open state, & vice versa.

Damping: This is determined directly on the trip curve by computing the velocity in the damping zone or the time between two predetermined places on the travel curve in the damping zone.

Contact Wipe: The total length measured from initial contact touch to final resting posture following the relevant procedure.

Over-Travel: Over-travel, as measured directly from the travel curve, is the maximum displacement which the contacts may achieve beyond their resting position.

Rebound: The lowest displacement (after over-travel) to the contacts’ final resting position.

Aesthetic tests, which are as significant and involve a thorough inspection of the switchgear & control gear to ensure compliance with their individual procurement requirements.

These tests include a thorough examination of the language and information used on the respective nameplates, the identification of any auxiliary equipment, the color and quality of the paint and corrosion-protection materials used on metallic surfaces, & the values of the resistors & capacitors connected to main circuit.

RELATED ARTICLES MORE FROM AUTHOR

Disconnector switch testing procedure, how medium voltage switchgear (mvsg) works, explain air circuit breaker (acb) and their working principle.

What happens when you press the TEST button on a circuit breaker in an electric panel?

Thursday, July 12, 2018

All circuit breakers provide “overcurrent protection.” This means that, if current in excess of the breaker’s rating in amps is flowing through the circuit, the breaker will trip and disconnect the circuit to avoid overheating the wiring or equipment it serves, which could potentially start a fire.

Breakers with a small colored button marked “TEST”—it could be white, yellow, green, or red—have a dual protective function. And older GFCI breaker from the 1980s with a red test button is shown below.

There are two primary types: GFCI (Ground Fault Circuit Interrupter) and AFCI (Arc Fault Circuit Interrupter). When the test button is pushed the device simulates the defect that it s designed to protect against, and trips the breaker to the middle position if functioning properly. To reset, you push the breaker switch all the way to “OFF” and and then back to “ON.” If nothing happens when the test button is pushed, that means the device is not functional and therefore not protecting the circuit in the way it was designed.

The GFCI-breakers protect against ground faults, which is essentially current that is traveling off the intended circuit and may be shocking you. These breakers protect circuits for pools and spa tubs, along with receptacles in wet areas like bathrooms, kitchens, garages, and exterior. Because GFCI-protection can also be provided by GFCI-receptacles with “TEST” and “RESET” buttons in the center, GFCI-breakers are used less often in panels today, with GFCI-receptacles placed around the home in the wet areas instead.

Also, see our blog post Where are GFCI receptacle outlets required? and What electrical hazards does a Ground Fault Circuit Interrupter (GFCI) NOT protect against? and When did arc fault circuit interrupter (AFCI) breakers first become required? and Are Ground Fault Circuit Interrupters (GFCIs) really necessary and worth the trouble

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Here’s links to a collection of our other blog posts about AFCI and GFCI RECEPTACLES AND CIRCUIT BREAKERS:

• Does a septic pump or sump pump require a GFCI-receptacle?

• What is the difference between what trips a GFCI (ground fault) receptacle and a circuit breaker?

• What is the code requirement for GFCI protection for receptacles near a wet bar sink?

• When was GFCI-protection for kitchen dishwasher receptacle outlet first required?

• Does a washing machine receptacle outlet require GFCI protection?

• My spa tub stopped working. What's wrong?

• How do I identify a combination AFCI (CAFCI) circuit breaker?

• What does "listed and labeled" mean for an electrical component?

• What is the difference between GFCI and AFCI circuit breakers?

• When were GFCI receptacle outlets first required?

• What is the difference between the electric service to a mobile home and a site built home?

• Why is there a wall switch next to the furnace or indoor unit of the air conditioner in the garage?

• What is a Dual Function Circuit Interrupter (DFCI)?

• How I can tell if a receptacle outlet is tamper resistant?

• What is the difference between a Combination Arc Fault Circuit Interrupter (CAFCI) and an Arc Fault Circuit Interrupter (AFCI) circuit breaker?

• What is the difference between "grounded" and "grounding" electrical conductors?

• How far above a kitchen countertop do electrical outlets have to be?

• How is it possible to provide both GFCI (Ground Fault Circuit Interrupter) and CAFCI (Combination Arc Fault Circuit Interrupter) protection for kitchen and laundry circuits?

• My bathroom electric receptacle/outlet is dead and there are no tripped breakers in the electric panel. What's wrong?

• My GFCI reset button is hard to push and won't reset. What's wrong?

• Why do some breakers in my electric panel have a "TEST" button on them?

Visit our ELECTRICAL page for other related blog posts on this subject, or go to the INDEX for a complete listing of all our articles.

Water Heaters

Water Heater Age

"What Are The

Signs Of..."

Septic Tank Systems

Structure and Rooms

Plumbing Pipes

Termites, Wood Rot

When It First

Became Code

"Should I Buy A..."

Park Model Homes

Shingle Roofs

Wind Mitigation

Roof and Attic

"Does A Home

Inspector...?"

Pool and Spa

"What Is The Difference Between..."

Concrete and

Concrete Block

Metal Roofs

Foundations

Modular Homes

Rain Gutters

Mold, Lead & Other Contaminants

Condominiums

Historic Houses

Crawl Spaces

Mobile-Manufactured Homes

Building Permits

Life Expectancy

Exterior Walls

& Structures

Common Problems

HUD-Code for

Mobile Homes

Garages and Carports

Flat (Low Slope) Roofs

Electrical Panels

Sprinkler Systems

Electrical Receptacle Outlets

4-Point Inspections

Hurricane Resistance

Frequently Asked Questions (FAQ)

Home Inspection

Heating and Air Conditioning

Building Codes

Fireplaces and Chimneys

Inspector Licensing

& Standards

Energy Efficiency

Washers and Dryers

Doors and Windows

Electrical Wiring

Click Below

to Collections

of Blog Posts

Plumbing Drains

Smoke & CO Alarms

Aging in Place

Top 5 results given instantly.

Click on magnifying glass

for all search results.

AFCI, CAFCI,

DFCI, & GFCI

Air Conditioner & Furnace Age/Size

Electrical Switches

Water Intrusion

Electrical - Old

and Obsolete

Foundation Certifications

Tiny Houses

About McGarry and Madsen

Buying a home in North/Central Florida? Check our price for a team inspection by two FL-licensed contractors and inspectors. Over 8,500 inspections completed in 20+ years. In a hurry? We will get it done for you.

Moisture Problems

Schneider Electric Blog

Home > Infrastructure and Grid > Power Distribution and Management > LV Circuit Breaker Testing – Learn when, why, and how to perform it and the role new software plays

Power Distribution and Management

LV Circuit Breaker Testing – Learn when, why, and how to perform it and the role new software plays

February 24, 2022

6 min read | Mathieu Guillot

JavaScript is required to use the TTS Player.

This audio was created using Microsoft Azure Speech Services

Circuit breakers help ensure the safety and reliability of electrical distribution systems in all facility types. Low-voltage (LV) circuit breakers need checking to ensure proper configuration to operate as expected during their entire lifecycle.

This validation is the combined responsibility of specifiers, panel builders, installers, and service technicians. This post explains why, when, how, and by whom should perform testing and how the newest software makes it faster and easier to perform and share test reports.

The importance of properly configuring LV circuit breakers

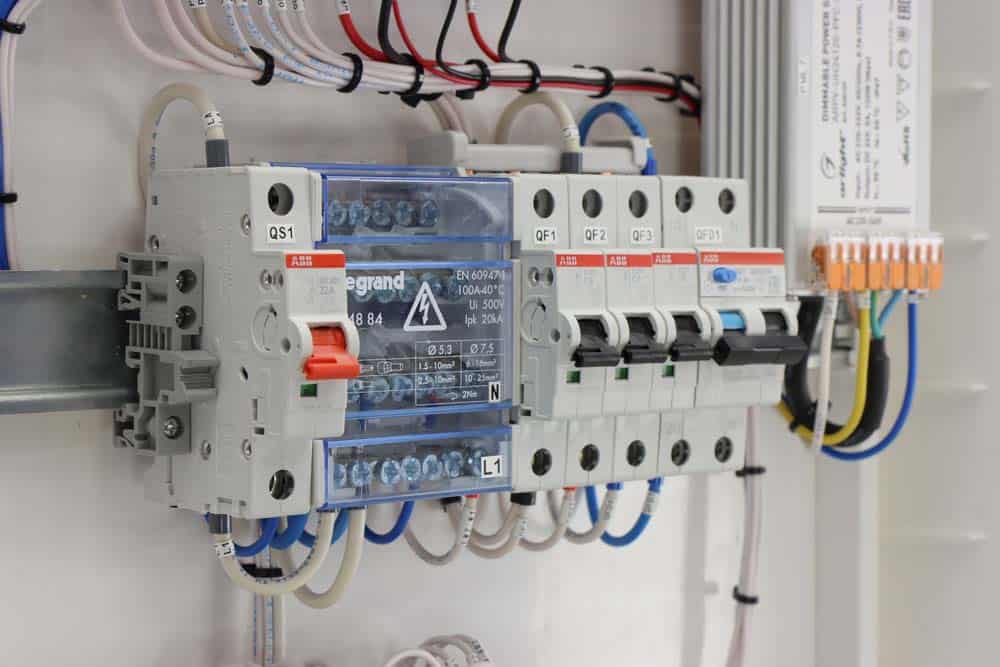

Most of today’s circuit breakers designed for simple protection functions in final distribution applications are non-adjustable, so they do not require any unique configuration.

However, circuit breakers designed for LV applications above 100A in main switchboards – i.e., molded case circuit breakers (MCCB) and air circuit breakers (ACB) – typically integrate protection for many fault conditions, like overload, short circuit, and earth fault. Many of these breakers configure to coordinate protection between each other – using selectivity and cascading – to help minimize impacts of electrical faults while preserving supply continuity for the rest of a facility. Circuit breakers offering this level of protection and reliability have adjustable settings that need configuration.

During the design phase of a new facility, upgrade, or expansion, the latest advanced software design tools, such as ETAP or Caneco ONE , can specify settings for each circuit breaker in an electrical system based on various parameters, e.g., cable cross-section. To optimize safety and reliability, it is essential that the specified breaker settings during the design stage are applied to each circuit breaker and maintained to ensure optimized performance during electrical instillation’s operational lifecycle.

Circuit breaker checking validates the configuration

There are three important reasons to check circuit breakers to certify proper configuration and operation:

- Safety – The ability of a circuit breaker to reliably disconnect in the case of overcurrent or earth fault is a matter of property and people protection. Proper functioning relies on consistency between circuit-breaker setting, tripping curves, and power system characteristics (e.g., rated power of sources, impedances, length, and cross-section of cables).

- Continuity of supply – One way to solve the previous requirement is to have a very sensitive circuit breaker with a low threshold and time delay, but this will create issues due to unwanted tripping or selectivity issues. That will result in forcing settings to maximum values, potentially impairing safety. So the perfect compromise between safety and supply continuity is entirely dependent on the correct application of the settings calculated during design.

- Standards compliance – Part 6 of the IEC 60364-6 standard for LV installations – and multiple local regulations such as BS7671 and NFC15100 – require overcurrent protective devices tripping values to be checked during installation and periodically during operation.

Though circuit breakers must be properly configured, it is unfortunately prevalent that large numbers of breakers do not have their optimized settings configured when buildings are designed, constructed, and operated. We estimate that at least one-third of adjustable circuit-breaker remain with factory settings. There can be many reasons for this:

- According to the actual installation, the initial design calculation is done without the necessary information and is not current. For example, it is typical that the load list may evolve, cable types and lengths may change, or the setting capability is more than initially calculated for a circuit breaker.

- No one thinks it’s their responsibility to configure the circuit breakers.

- Settings are manual, and checking is visual, increasing the chance of human error.

- Settings are modified during operation to solve an issue quickly.

If not configured, circuit breaker settings remain in their factory defaults. A circuit breaker with factory settings might still pass a building inspection, but there is the risk of:

- Non-conformity to the installation standard

- Non-selectivity or unexpected circuit breaker tripping for the installation

Checking circuit breaker settings during the construction phase and periodically during the facility’s operation will avoid these risks by ensuring conformity of the built installation with the calculations done during design. However, mandatory checking is usually performed visually. This poses a risk of human error with poor traceability.

Additionally, periodically testing circuit breaker s is an essential preventative maintenance step to help find early indications of a potential operational issue. Circuit breakers may be inactive for months or years before a fault. This will give you time to fix the issue before it can cause a problem.

Recommended steps for circuit breaker testing

As per the standards noted above, checking LV circuit breaker settings should be executed multiple times over the circuit breaker’s lifecycle. Here are some additional considerations:

Testing at the initial installation stage:

- Checking adjustable circuit breaker settings should be prescribed for all new electrical installations.

- The panel builder or electrical contractor should be responsible for this early verification phase.

- Before putting electrical equipment into operation, check the protection settings on circuit breakers and perform testing to verify the functioning of the breakers in accordance with these settings.

- Details of configuration should be entered into a digital logbook – such as EcoStruxure Facility Expert – to set a ‘baseline’ for the configuration and ensure traceability. This record should also include all details for the associated switchboard.

- The panel builder or contractor performing the settings check should deliver a test report to the specifier and building owner to ensure correct settings and operational tests. This should be delivered before starting the installation.

Periodic testing during facility operation:

- For example, the contracted electrical service, a Schneider Electric EcoXpert ™ partner, should be responsible for this stage of checking settings and testing performance.

- Though the IEC 60364-6 standard specifies that the testing period is dependent on the installation, equipment, and type of operation. For example, for the ComPacT NSX from Schneider Electric, we recommend testing the trip curve every two years under normal environmental conditions.

- The test procedure should include testing the ability of the circuit breaker to detect an overcurrent and trip (including the mechanical part). It should also include checking that all settings are consistent with the original design specification, including protected circuit characteristics and selectivity objectives.

New technology makes circuit breaker testing simpler, faster, and more reliable

EcoStruxure™ Power Commission (formerly known as Ecoreach) is an intelligent digital testing tool compatible with all Schneider Electric circuit breakers with electronic trip units, power and energy meters, and communication gateways. EcoStruxure Power Commission is a software app that runs on a laptop computer. This mobility makes it ideal for circuit breaker initial validation testing before installation and periodic testing during facility operations.

EcoStruxure Power Commission automates setting, commissioning, and testing, making these steps safer, faster, and more reliable, with less human error. The newest version of this software is simplified to allow direct connection of the laptop to any Schneider Electric MasterPacT MCB or ComPacT MCCB circuit breaker with as little as a USB cable or Field Services Interface. It supports routine checkups, secondary injection testing, preparation for primary injection testing (if required in special cases), and zone selective interlocking testing.

Settings are automatically documented in a digital logbook to save time while enabling consistency and traceability. EcoStruxure Power Commission can also quickly and automatically generate a project report to share with all stakeholders to give them peace of mind that circuit breakers are correctly configured and performing safely and reliably.

In the future, we envision digital design tools like ETAP or Caneco BT software to offer seamless connectivity between the ‘digital twin’ and EcoStruxure Power Commission. This will enable direct upload of specified settings for each breaker in the electrical system for even greater time savings.

To learn more, discover EcoStruxure Power Commission , watch our demonstration video, or download our eGuide .

Tags: Caneco ONE , EcoStruxure Facility Expert , EcoStruxure Power , EcoStruxure Power Commission , ETAP , Low Voltage Circuit Breaker , LV Circuit Breaker Testing , LV electrical installations , selectivity

Optimizing installation costs with circuit breaker cascading

Circuit breaker selectivity for power availability

Circuit breaker innovation drives today’s quality and reliability standards

3 Extreme Conditions that Put Low Voltage Circuit Breaker Reliability at Risk

Sprinkler Age A Publication of the American Fire Sprinkler Association

Dry System Valve Trip Testing

April 17, 2019 Featured Articles , Technical Articles Leave a comment

All That It Entails

With all that NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems , includes, few things are as straight forward as the trip testing of a dry system valve. Straight forward, however, does not mean uncomplicated. So, don’t lose focus during this test procedure or you’ll find yourself having to perform it all over again to get the information needed for a proper functional test. Of course, that goes for any test where one may think the results are not accurate, but it is one thing to re-perform the testing of a wet system or even a fire pump three-point flow test. It is an entirely different burden to have to drain, reset, and pump up a dry valve in order to retest it a second time. What’s the famous saying? You know it… if you don’t have time to do it right the first go around, where is the time going to come from to do it correctly the second go around?

This article will cover the most important areas on which to focus in the hopes of helping to avoid the costly and time-consuming dry trip retest. Let me start by saying that if you’re reading this article then dry system valve trip testing is probably something with which you are familiar and already understand. With so many variations of dry system valves and set ups, this article is meant to be a refresher or a checklist for you to confirm what you already know; it is not meant to be the “end all be all” to dry system valve trip testing. So, with the disclaimer out of the way, let’s get to it.

The most important thing to do with a dry system valve is slow down… slow way down. This equipment is touchy and once tripped, leaves no chance to go back and get your previous static pressures (air, water, quick-opening device, etc.). So upon walking up on one, look it over and take some notes. Firstly, notice if there is a quick-opening device (QOD) and what pressure is on it. Also, pay attention to whether there is a low-pressure actuator or a standard actuator and then validate by verifying that the pressure concurs with the system gauge. Keep in mind that the QOD also has to match the actuator as either standard or low-pressure; they don’t mix and match. It is not uncommon to walk up on a dry valve and have the QOD out of service or have a low-pressure actuator with 38 pounds of air or nitrogen on the system. Those low-pressure actuators should have between 13 and 18 pounds of air or nitrogen in them according to the manufacturer, not 38. Additionally, find the air compressor or nitrogen generator and confirm that it is operational before attempting the trip test. If it’s not working, you won’t be able to pressurize the system without repairing the unit or bringing in temporary air or nitrogen to use. Notice the water pressure on the system; is it fed from city pressure or is there a pump supplementing the pressure? All of these things affect the performance and accuracy of the test results. Remember the reason for performing the test – to ensure the functionality of the valve to operate if it is needed. Therefore, the starting parameters need to be accurate in order to ensure the final results are accurate. Finally, pay attention to the temperature. Dry system valves shall be trip tested during the warm seasons when there is time to drain down the piping prior to freezing weather.

After assessing the equipment on the system to be operated and documenting all of the pressures, the technician will need to understand what kind of test is going to be performed. Dry system valve trip testing can be performed as a partial trip test or as a full flow trip test. The full-flow trip test is conducted every third year with the control valve fully open. The water delivery time to the most remote outlet is compared to the system acceptance results. Longer water delivery times could mean the degradation of the system or water supply, resulting in significant delays in system operation. By contrast, a partial trip test is performed the other years with the control valve partially open to prevent the system from filling with water. It does not require water delivery to the most remote outlet. The full-flow test procedure requires two people to perform where the partial trip test procedure can be performed with one technician as long as the control valve is not a wall post indicating valve (WPIV) or a post indicating valve (PIV).

So far there has been a whole lot of looking, assessing, and organizing but we haven’t touched a thing. We’ll perform the procedures for the partial dry trip test first. Let’s assume the customer is expecting you and they have already notified the local fire department, if required, and the monitoring company has the system on test. Before the test is conducted, make sure that the area where water will be discharged can handle the volume and pressure and that it is safe to discharge. Then,

• Record the air or nitrogen pressure on the QOD (if it exists and confirm it matches with the actuator, if one exists) and on the system side of the valve, taking note if a low-pressure or standard actuator is installed.

• Record the water pressure on the supply side of the valve.

Note: At this point, the technician should follow the pre-planned impairment procedures in Chapter 15 to secure the fire pump (if it exists). Technicians should follow their company procedures as they align with NFPA 25.

• Fully open the main drain and flush the water supply. While the main drain is flowing, slowly close down the system control valve until the main drain can no longer provide flow through the entire outlet. Some water needs to be exhausting from the drain; do not close the system control valve tightly.

• Fully close the main drain.

Note: The technician can choose to close the QOD (if it exists) or leave it in service. The QOD has to be tripped quarterly so this may be a good time to perform that test. The technician should follow their company’s procedure whether to perform the QOD trip as part of the dry trip or as a separate test after the dry trip.

• Open a valve on the system to release the air or nitrogen.

• Watch the system air or nitrogen gauge and document the pressure at which the dry valve trips.

• Immediately close tightly the system control valve and fully open the main drain valve.

• Fully close the air or nitrogen supply valve and the QOD supply valve (if it exists).

• Fully open the inspector’s test valve and the auxiliary drain valves on the system to allow them to drain any accumulated condensation.

Note: The location of auxiliary drain valves shall be listed at the riser.

• While resetting the interior seat of the dry valve, clean it and make sure the seat will open fully and latch.

• Confirm that the pressure switch flow alarm and the control valve and low air or nitrogen supervisory signals were received at the fire alarm control panel (FACP).

Note: Make sure the dry valve system is not equipped with a paddle style flow switch and be mindful of the order the switches were received at the FACP. Occasionally, switches have been wired or identified incorrectly.

• Reset the seat of the dry valve system and the QOD (if it exists) and apply priming water to the actuator of a newer valve or to the top of a differential dry valve system.

• Fully close all auxiliary drain valves and the inspector’s test valve.

• Fully open the air or nitrogen supply valve.

Note: The air or nitrogen supply shall be able to restore system air or nitrogen pressure to normal within 30 minutes through the bypass connection. If multiple systems exist, the 30-minute fill requirement is only applicable to one system at a time. Technicians may use a supplemental supply to bring multiple systems to normal pressure but the 30-minute requirement must be confirmed using the installed compressor.

• When system air or nitrogen pressure is restored, open the QOD supply valve (if it exists). Document the air or nitrogen pressure on the system side of the dry valve and on the QOD (if it exists).

Note: Compare the two. They should be very similar.

• With the main drain still open, slowly open the system control valve until water starts to release from the main drain. Continue slowly opening the system control valve until it is fully opened and the main drain is fully flowing. Document your residual pressure.

• Slowly close the main drain fully so as to not cause water hammering. Document your return to static pressure.

Note: The technician may choose to close the main drain after partially opening the system control valve to allow water pressure to build up under the seat. However, the technician will be required to perform a valve status test if it is not performed at the time of setting up the valve as described above.

• Hang the system tag with pertinent information at the dry valve system.

• Return the fire pump (if it exists) to normal operation.

• Reset the fire alarm control panel and confirm its status is normal.

Now, let’s take a look at how the full flow dry trip test compares to the partial trip procedures from above. Keep in mind, for this test there will need to be two people present and the use of radios or communication of some kind will be imperative. Certainly one, but I prefer both technicians to have a stopwatch. If a pump exists and it is remote from the location of the valve or the inspector’s test, then a third person will need to be present in the pump room while the pump is running. We’ll make the usual assumptions that we made above and we’ll start the test procedure at:

• Record the air or nitrogen pressure on the QOD (if it exists and confirm it matches with the actuator, if one exists) and on the system side of the valve, taking note if a low pressure or standard actuator is installed.

• Record the water pressure on the supply side of the valve.

Note: At this point, the technician should follow the pre-planned impairment procedures in Chapter 15 to secure the fire pump (if it exists). Technicians should follow their company procedures as they align with NFPA 25.

• Fully open the main drain and flush the water supply.

• Fully close the main drain slowly.

Note: Restore the pump that was impaired per Chapter 15 to normal operating service at this time. It will be needed for the full-flow dry system valve trip test.

Note: At this point, one technician should be stationed at the most remote inspector’s test valve and the other technician at the riser. When the next step is initiated, both technicians will start their stopwatches in order to time the tripping of the dry system valve and the delivery of a full stream of water at the inspector’s test valve.

• Open the inspector’s test valve on the system to release the air or nitrogen. (Timing begins.)

• Watch the QOD gauge (if it exists) and document the pressure when the QOD (if it exists) trips.

Note: This should happen quickly and will most likely result in the dry system valve tripping instantaneously, so be watching both gauges simultaneously as best you can.

• Watch the system air or nitrogen gauge and document the pressure at which the dry system valve trips.

• Document the time at which the dry system valve trips. Call out to your coworker that the system tripped.

• Document the water pressure at the time the dry system valve tripped.

• Confirm operation of the fire pump (if it exists).

• Close the air or nitrogen supply valve and the QOD supply valve (if it exists).

• When a steady flow of water is reached at the inspector’s test valve, the coworker should stop the timing and call in the time to the technician stationed at the riser.

• Document the time it took for water to reach the inspector’s test valve.

• When a steady stream of clear water is present at the inspector’s test valve, close tightly the system control valve.

• The technician should follow the pre-planned impairment procedures in Chapter 15 to secure the fire pump (if it exists).

• While resetting the interior seat of the dry system valve, clean it and confirm it latched in the open position.

Note: The full-flow test shall latch the clapper in the open position.

• Confirm that the pressure switch flow alarm and the control valve, low temperature, and low air or nitrogen supervisory signals were received at the FACP.

Note: Make sure the dry valve system is not equipped with a paddle-style flow switch and be mindful of the order the switches were received at the FACP. Occasionally, switches have been wired or identified incorrectly.

• Reset the seat of the dry system valve and the QOD (if it exists) and apply priming water to the dry system valve.

• Fully close all auxiliary drains and the inspector’s test valve.

Note: The air or nitrogen supply shall be able to restore system air or nitrogen pressure to normal within 30 minutes through the bypass connection. If multiple systems exist, the 30-minute fill requirement is only applicable to one system at a time. Technicians may use a supplemental supply to bring multiple systems to normal pressure but the 30-minute requirement must be confirmed using the installed compressor.

• Slowly close the main drain fully so as to not cause water hammering. Document your return to static.

So, in a nutshell, there you have the basic differences between the partial trip test and the full flow dry system valve trip test. I would be remiss if I didn’t reiterate that there are a multitude of system configurations for which a technician needs to be looking, which was the purpose of my first two paragraphs. Additionally, the air compressor or nitrogen generator maintenance, the heating of the riser room, and the draining of auxiliary drum drips are a continual task of which the owner needs to be aware, especially at the onset of cold weather and during freezing weather. These three topics have enough information to fill their own article which is coming shortly. For now, take your time, be aware of the purpose of the equipment you see, and have good documentation so that you can successfully communicate the accurate results of the testing you just performed. Unlike golf, taking a mulligan on a dry system will cost you, and perhaps your boss, a stroke.

ABOUT THE AUTHOR: Howard Clay is employed by VSC Fire & Security, Inc. in its Inspection Division. He received his B.A. in managerial economics from Hampden-Sydney College. Clay is NICET certified in water-based fire protection systems, fire alarm systems, and fire alarm inspections and testing. He holds state backflow prevention testing licenses in both Virginia and North Carolina and carries the FS-IT-C inspection and testing certification in North Carolina. Clay represents AFSA on the NFPA 25 Committee. He has authored articles for magazines of local organizations and has been asked to speak to local businesses, fire departments, and community associations to help them better understand fire protection. Clay is an instructor for AFSA’s ITM Inspector Development program and is a member of the National Association of Fire Investigators (NAFI) and the International Association of Arson Investigators (IAAI). He can be reached at [email protected].

IMPORTANT NOTICE: The article and its content is not a Formal Interpretation issued pursuant to NFPA Regulations. Any opinion expressed is the personal opinion of the author and presenter and does not necessarily present the official position of the NFPA and its Technical Committee.

Did you enjoy this article? Subscribe for FREE!

Tags dry system valve trip test dry systems ITM

AFSA: Your Education Destination

ITM, Hydraulic Calculations, Design, and Apprenticeship Programs Offered In-Person and Virtually The American Fire Sprinkler …

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

CDL Pre-Trip Inspection Test and How To Memorize It

The pre-trip is one of the things that students fear the most and fail the most. Let’s face it, the pre-trip is intimidating because there is so much stuff to memorize. The key to learning the pre-trip inspection is preparation, memorization, and repetition. Don’t go away, in this article I have exactly what you need to make sure you pass it the first time.

It is going to take time for you to memorize everything and the only way to do this is by repeating it over and over.

Hopefully, the school where you are being trained is giving you enough time to practice it everyday you are there.

I can’t stress that enough, regardless of which method you use below you need to repeat it daily and practice on your own.

Don’t expect that your run through once a day with your instructor is enough, it isn’t.

In this article I’m going to give you 8 tips that will help you memorize the pre-trip so you are able to pass it your first time and move on with your driving career.

1. REPETITION!

The only way to memorize the pre-trip is to repeat it over and over. Start with the engine area and work your way around the truck and finally inside the cab.

There is no way around consistent repetition. The more you do it the more you will memorize it. It’s just that simple.

Now that we have established how important repetition is I want you go through the rest of this list and figure out which method (or methods) works best for you and then repeat it over and over.

2. Record Someone Else

You can use YouTube to find a video of someone doing a pretrip and for the most part they work pretty well (more about YouTube later).

Take it a step further though. Ask someone (like and instructor or friend) to do a pre-trip and video record them.

While they are doing it try to use the zoom function on your camera so that you know what the parts look like and what is being checked.

Students that I come across have said that this method works really well because you have quality video and audio. Just watch your recording over and over and this stuff will be engraved in your brain.

Just make sure you are absolutely sure that the person you record knows what they are doing and are showing you everything. You don’t want to watch a video that skips anything that will be on the test.

3. Smaller Chunks

Break down the pre-trip into smaller chunks so that it is not overwhelming. If you think about memorizing everything at once it will be a daunting task.

My suggestion is you learn your air brakes first, then the inside of the cab, the engine compartment, and then the rest of the truck. You can chose any order that you want to as long as it helps you out.

Memorize each part and then tie it all together. You will find that learning the pre-trip is much easier if you do it this way.

4. Use Your Imagination

Do this while in bed before you fall asleep. Warning: the pre-trip is going to consume a lot of your attention during training, even while you sleep!

When you wake up go through a video you found on YouTube or the one you recorded (see #2) and correct any errors you made.

5. Find A Truck

It really helps if you have access to a truck. Pictures alone are not enough. Most of you are probably getting your training through a private school, company sponsored training , or community college.

All of these will give you access to an actual truck and should be taking time each day to practice the pre-trip.

Take advantage of this time with the truck to practice your pre-trip as much as possible. When class ends try to stick around to get in some extra practice, this could be the difference between passing and failing.

6. Watch A Pre-Trip Video On YouTube (not straight through)

There are a lot of videos on YouTube that you can choose from. Let me save you some time, these two (below) is the best because it has good audio and video quality, is accurate, and is easy to follow.

Don’t watch the video straight through over and over. Like I mentioned earlier you should chunk it into smaller sections.

Watch a section, pause it, and list off the names of the parts and things to look for. Play it again to see if you are getting them correct. When you finish one section go on to another section until you finish it.

Don’t move on to a new section until you have memorized the section you started. When you complete all the sections you should be able to watch the whole pre-trip and repeat everything on it from start to finish.

If you want to challenge yourself a little try mixing up the sections so that the sections that was last is now first. This will let you know if you are really memorizing everything.

7. Use A Checklist

Probably the most popular ways to memorize the pre-trip is to use a checklist. No doubt that wherever you are getting your training at is already giving you a checklist to use.

Use it. A lot.

Not all checklists are done in the same order but they should all cover the same stuff. I like this one here (printable PDF document) by the people at Trucking Truth , it’s easy to follow and is accurate.

Every possible thing that you will need to identify during the pre-trip is on this checklist.

8. Use Pictures/Diagrams

There are a ton of picture resources out there that will help you memorize the test. Just do a search for “cdl pre-trip inspection pictures” and you will find a ton of stuff.

The picture I like most are these (link to PDF) by Driver Solutions. The pictures are easy to see and distinct arrows are used to point to each part. Along with pictures is an explanation of what to look for and what to say for each individual part.

What Is The Pre-Trip Inspection?

The pre-trip inspection is an inspection of the commercial vehicle including the cab, engine compartment, and exterior.

A driver of a commercial vehicle is required, by federal law, to complete one every day before driving the vehicle and at least once in a 24 hour period. Every single time you begin driving your truck you will have to complete a pre-trip.

The purpose of it is to make sure that the vehicle is safe to drive.

This gives you a chance to get whatever is wrong fixed. If you miss something and are inspected it could result in citations by the DOT.

A lot of drivers find it to be a pain in the rear but you really need to do it every single time you drive your truck. Don’t listen to the irresponsible driver at the truck stop that tells you it’s okay to skip it. It’s not okay.

How Long Does An Inspection Take?

A pre-trip usually takes about 15-45 minutes to complete. It really depends on the type of truck you are inspecting and your experience.

After several years of driving it’s inevitable that your pre-trip is going to be quicker because you are better at doing it and you know what to look for.

As a new driver you should take your time and make sure you do it right. Make it a habit to always conduct a thorough inspection so that you run into less problems while on the road.

What To Say During The Pre-Trip Test

Knowing what to say is important during the test. There are some specific language the person testing you is going to be listening for. More than likely you already heard these phrases but here is an easy way to remember what to say:

PMS— Properly Mounted, Secure ABC— Abrasions, Bulges, Cuts CBB— Cracked, Bent, Broken

There are some tricks that you can use to make sure you say the right thing, here they are: 1 . If its mounted (almost everything is) use the words, “Properly Mounted, Secure” (PMS) 2. If its rubber use the words, “Abrasions, Bulges, Cuts” (ABC) 3. If it’s metal or another hard surface use the words, “Cracked, Bent, Broken” (CBB) 4. If it has fluid or air going through it or in it remember to say, “Not Leaking”

This language shouldn’t be new to you, hopefully the school that is training you has already taught you this stuff.

What Should You Cover During The Pre-Trip?

The areas that you should cover include the coupling system, light check, in-cab inspection, engine compartment, trailer, and drivers door fuel area. Make sure that you are prepared for all of these.

Also, keep in mind that CDL schools/classes may cover the pre-trip in different orders. It’s okay though, they all cover the same stuff. The order that you practice is probably going to be different from someones in a different school/class.

There is no correct order as long as you memorize everything.

What Will Be Tested On The Actual State Pre-trip Inspection Test?

You will be required to perform a pre-trip for the light check, the in-cab inspection, and the coupling system. These 3 areas you have to complete.

After completing those 3 areas your examiner will have you perform one of the following: the engine compartment, trailer, drivers door fuel door, or the entire vehicle.

You will not know ahead of time which one the examiner will choose. This is why it is crucial that you know all the areas.

What Else You Can Do To Prepare?

Aside from the ways listed above to help you memorize the pre-trip there are some other things you can do.

One thing you can do is try answering some practice tests like these here from Trucking Truth. There are 5 free practice tests you can take.

I really find that these practice tests reinforce what you need to know for the real test. It’s worth your time try them out just to see how you do.

What If You Fail The Pre-Trip?

If you do fail the pre-trip you are able to retake it. Make sure you know why you failed the test, ask the inspector if he/she can specifically tell you what you did wrong.

This is usually never a problem because the inspectors want you to know what you missed so that you can pass the test the next time.

One more thing, don’t be embarrassed because you didn’t pass it on your first try! This happens to a lot of people! You are not the only person that will fail the pre-trip and you won’t be the last.

Study what it is that you missed/did wrong and pass it on your second attempt.

Extra Tips For Passing The Pre-Trip Test

Probably the most common reason people fail the pre-trip is because they are nervous.

The two things that will help you out the most is to always remember that the pre-trip is a verbal contact test.

As you start walking towards the vehicle you should already be looking for any leaks under it, broken marker lights, loose mirror brakes and anything else that seems out of place.

BE VERBAL! Your number one priority is to make sure the examiner knows that you know what you are talking about. The more you talk the greater your chances are to pass the test.